Device for debonding and cleaning fish oosperm

A fertilized egg and debonding technology, which is applied in the field of fish fertilized egg hatching equipment, can solve problems such as unstable debonding agent uniformity, irregular operation, and high labor intensity of manual operation, and achieve standardized cleaning procedures and solve Inhomogeneity, to achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

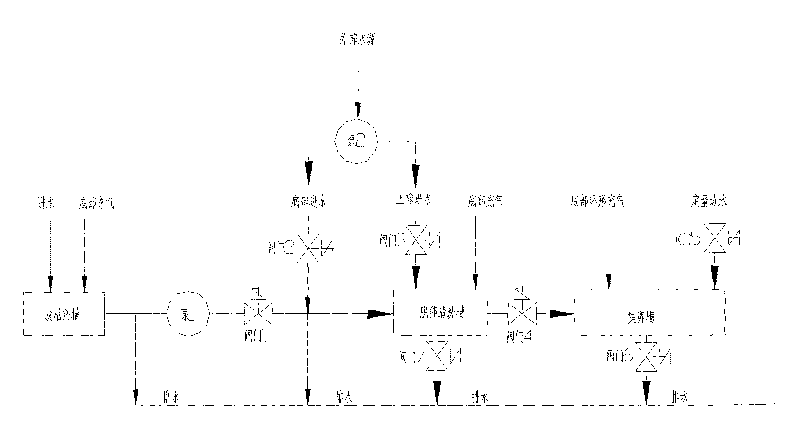

[0042] The method and equipment structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] The use of debonding and cleaning equipment for fish fertilized eggs in the hatchery production of allogenetic gibel carp.

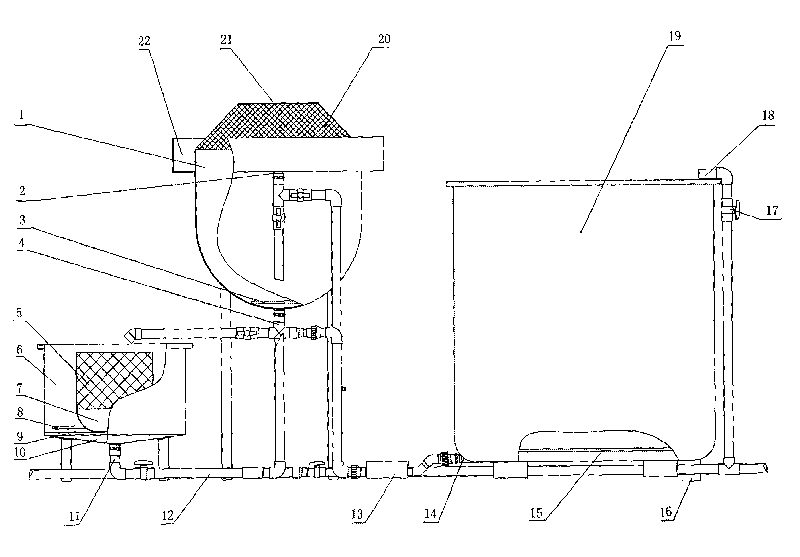

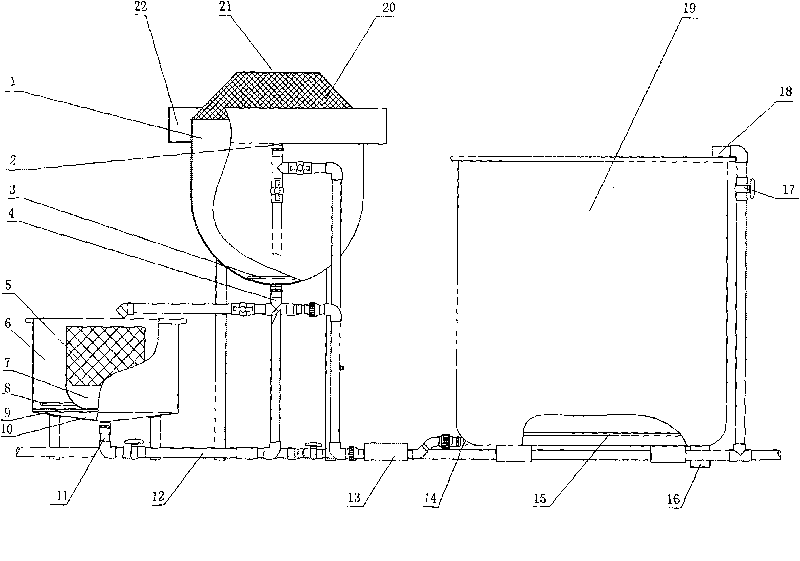

[0044] A debonding and cleaning equipment for fish fertilized eggs, the equipment includes three parts: a debonding agent tank 19, a debonding cleaning tank 1 and an egg collection tank;

[0045] The debonding agent tank 19 is a cylinder or box with an open top, with a water inlet pipe 18 arranged above, and a discharge port 16, an agent discharge pipe 14 and an inflator 15 arranged at the bottom;

[0046] The debonding cleaning tank 19 is in the shape of a round-bottomed pot or a conical bottomed pot. A discharge pipe 4 is arranged in the center of the bottom of the debonding cleaning tank 19, and a storm ring 3 is arranged horizontally overhead. Install a tapered screen ring 20 with the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com