Method for producing licorice plum

A production method and technology of licorice, applied in confectionery, confectionary industry, food science, etc., can solve the problems of potential safety hazards, failure to satisfy consumers' taste and preferences, and weak sweetness, so as to improve the taste and appearance quality, Long-lasting licorice flavor and unique taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

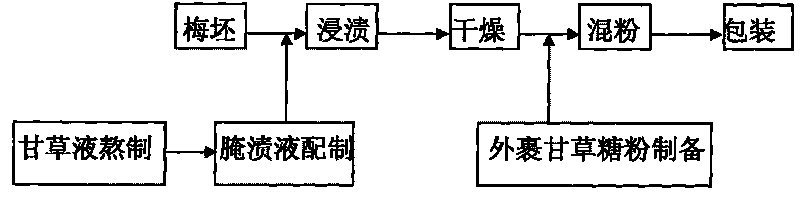

[0022] Embodiment 1: (preparation process flow chart is as figure 1 shown)

[0023] (1) Making plum blanks: the green plums are prepared by the prior art to obtain plum blanks with a moisture content of 8% and a salt content of 1.8%; 3g of plum blanks are soaked in 50mL of water for 5h, and the measured pH value is 2;

[0024] (2) Glycyrrhizae liquid boiling: crush the licorice, pass through a 60-mesh sieve, and collect the sieved licorice powder for later use; take 3kg of licorice powder that has not been sieved, boil it with 18kg of water for 20min, place it for 4h, and filter; filter the residue with 12kg of water Boil for 20 minutes for the first time, and filter; combine the above-mentioned filtered filtrates, mix well, and obtain the licorice liquid;

[0025] (3) Preparation of pickling solution: take 8% of the quality of the licorice solution obtained in step (2), add spice powder, heat and boil for 5 minutes; add the seasoning to the remaining licorice solution, stir ...

Embodiment 2

[0034] (1) Making plum blanks: green plums are prepared by the prior art to obtain plum blanks with a moisture content of 15% and a salt content of 2.8%; 3g of plum blanks are soaked in 50mL of water for 5h, and the measured pH value is 3.5;

[0035] (2) Preparation of licorice liquid: crush licorice, pass through a 80-mesh sieve, and collect sieved licorice powder for later use; take 5.5kg of unsifted licorice powder, boil it with 35kg of water for 40min, place it for 2h, and filter it with gauze; filter the residue with 14kg Boil with 8kg water for 40min, filter with gauze; combine the above-mentioned filtered filtrates, mix well, and obtain the licorice liquid;

[0036] (3) Preparation of pickling solution: take 12% of the mass of the licorice solution obtained in step (2), add spice powder, heat and boil for 15 minutes; add the seasoning to the remaining licorice solution, stir to dissolve, and then mix with the above-mentioned licorice solution added with spices , to obta...

Embodiment 3

[0045] (1) Making plum blanks: green plums are prepared by the prior art to obtain plum blanks with a moisture content of 10% and a salt content of 2.0%; soak 3 g of plum blanks with 50 mL of water for 5 hours, and measure the pH value to be 2.5;

[0046](2) Glycyrrhizae liquid boiling: crush licorice, pass through a 100-mesh sieve, and collect sieved licorice powder for later use; take 7kg of licorice powder that has not been sieved, boil it with 45kg of water for 50min, place it for 1h, and filter it with gauze; filter the residue with 18kg and Boil 11kg of water for 50 minutes respectively, filter with gauze; combine the above-mentioned filtered filtrates, mix well, and obtain licorice liquid;

[0047] (3) Preparation of pickling solution: take 15% of the mass of the licorice solution obtained in step (2), add spice powder, heat and boil for 20 minutes; add the seasoning to the remaining licorice solution, stir to dissolve, and then mix with the above-mentioned licorice solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com