Drill bit grinding device and testing method

A technology of a grinding device and a detection method, which is applied in the directions of drilling tool accessories, drilling/drilling equipment, grinding machine parts, etc., can solve the problems of increasing the inspection stroke of the drill bit, reducing the grinding efficiency and quality, and improving the efficiency. and accuracy, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

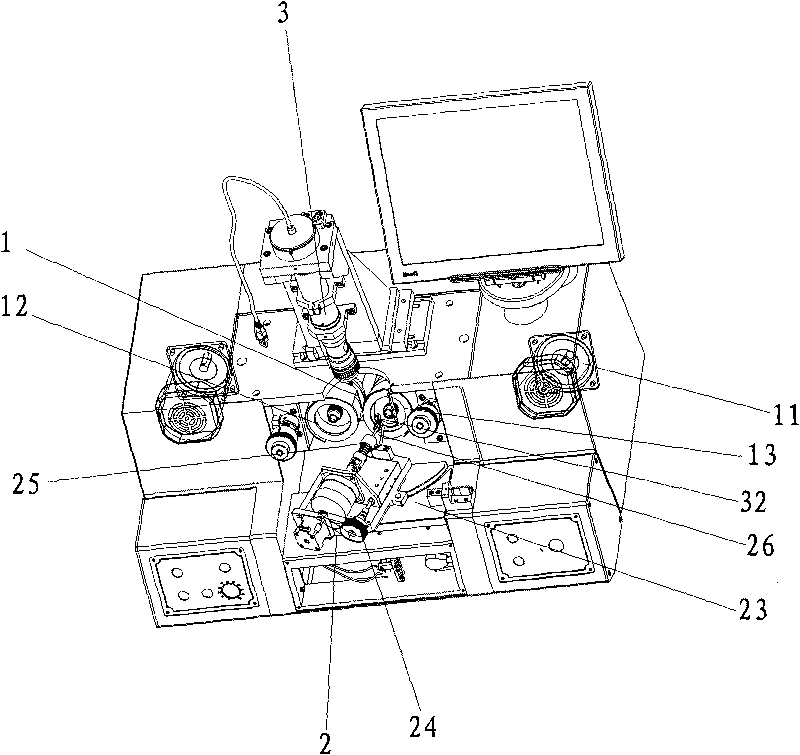

[0029] Please refer to figure 1 As shown, the drill grinding device includes a grinding wheel mechanism 1 for grinding the drill, a control device 2 for fixing and adjusting the position of the drill, and a first image acquisition device 3 for collecting images of the drill.

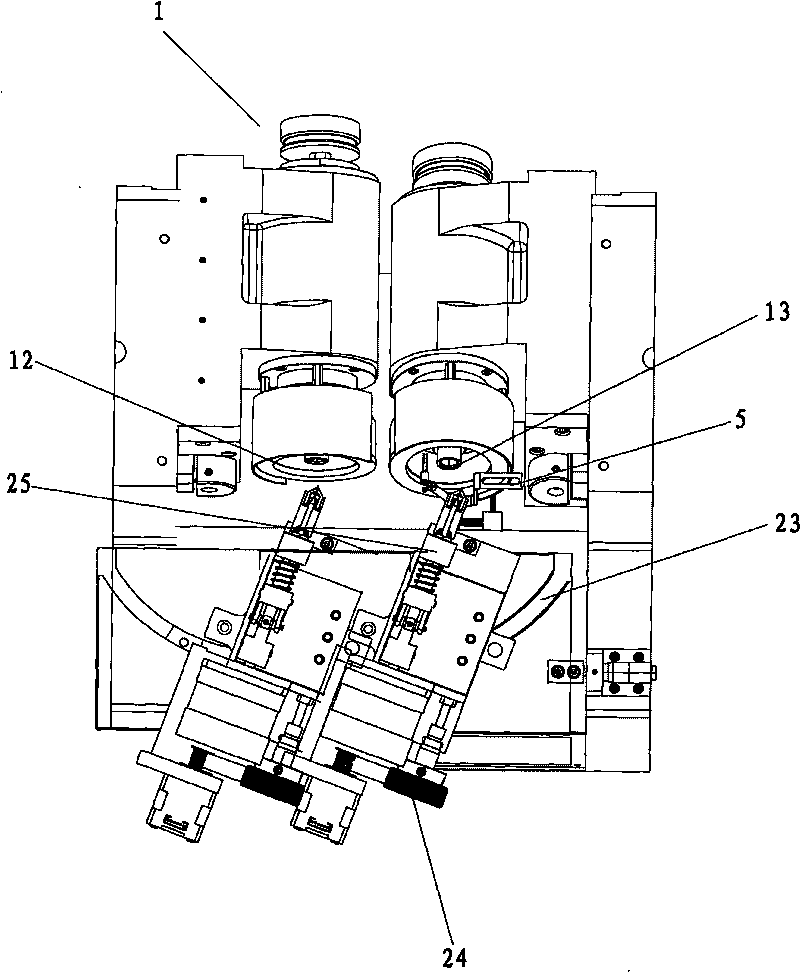

[0030] The grinding wheel mechanism 1 includes a first grinding wheel 12 and a second grinding wheel 13 driven by a motor 11 to rotate. When the first grinding wheel 12 and the second grinding wheel 13 are viewed from the side, the grinding edges of the first grinding wheel 12 and the second grinding wheel 13 are closely adjacent to each other or have a distance. side by side setting.

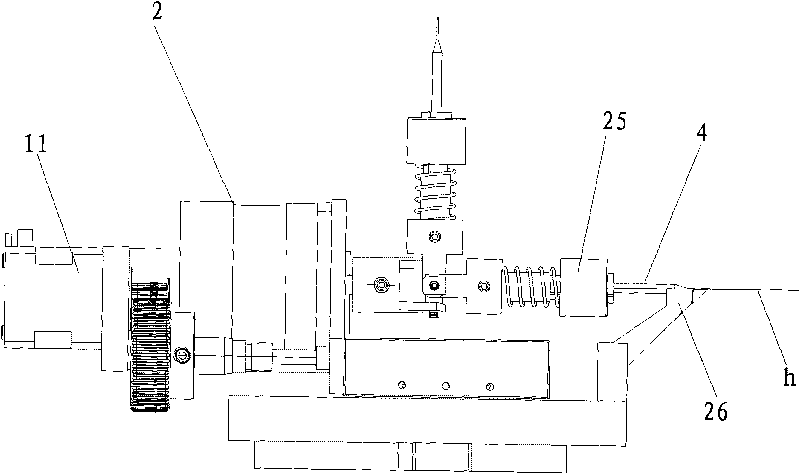

[0031] Please refer to figure 2 , image 3 , Figure 4 , Figure 5 As shown, the control device 2 is arranged on one side of the first grinding wheel 12 or the second grinding wheel 13, and the control device 2 is used to fix the drill bit and feed the drill bit to move the drill bit to the initial position to be gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com