Plasma-enhanced chemical vapor deposition PECVD equipment

A chemical vapor deposition, plasma technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the first cell effect and other problems, to improve product quality and production efficiency, improve quality and excellent Productivity, the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific structure of a plasma-enhanced chemical vapor deposition equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

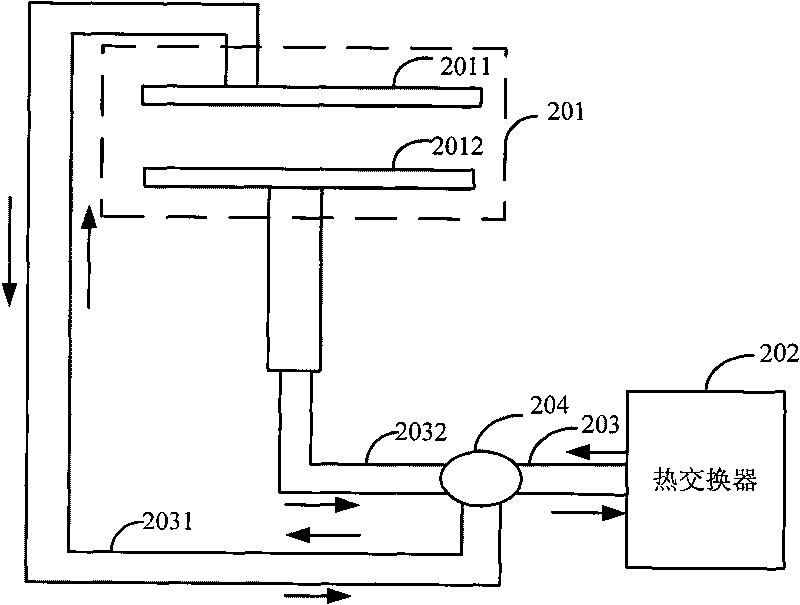

[0025] A kind of plasma-enhanced chemical vapor deposition PECVD equipment provided by the embodiment of the present invention, such as figure 2 As shown, it includes: PECVD deposition chamber 201, heat exchanger 202 and heat exchange pipeline 203;

[0026] The heat exchanger 202 is connected with the heat exchange pipeline 203, and is used for heating the fluid in the heat exchange pipeline 203;

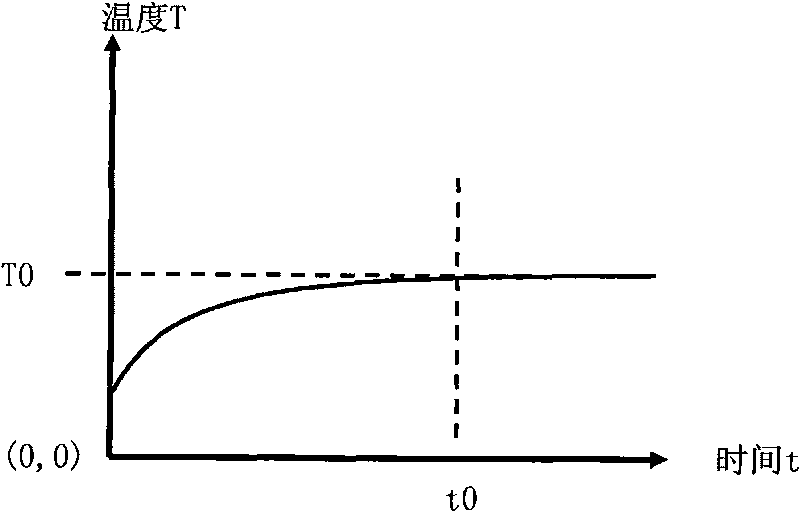

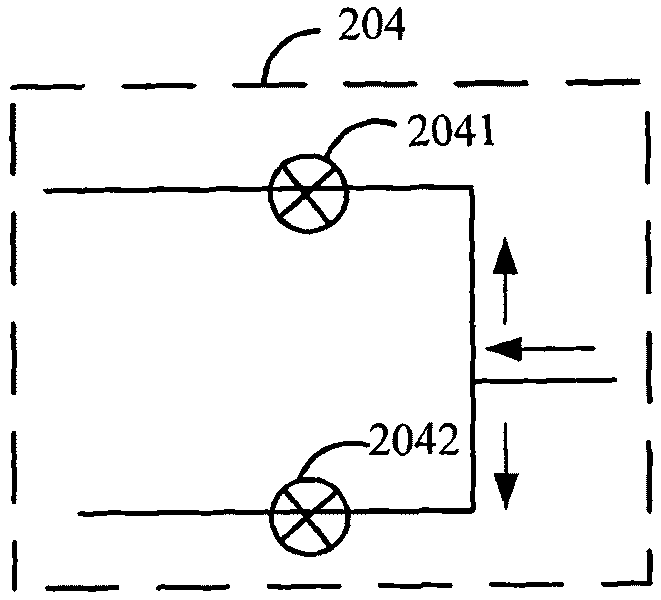

[0027] One end of the heat exchange pipeline 203 is connected to the heat exchanger 202; the other end is divided into two branches 2031 and 2032 leading to the support plate 2011 of the PECVD deposition chamber 201 and the substrate 2012 of the PECVD deposition chamber respectively for heating the support plate 2011 and base 2012 to reach the set temperature. The set temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com