Method for weaving coating terylene industrial yarn doup structure sunshade screen

A technology of polyester industrial yarn and sunshade net, which is applied in leno fabrics, leno fabrics, textiles and papermaking, etc. It can solve the problems of poor sun resistance, poor mesh stability, fine and dull gaps, and easy aging. Uniform, beautiful and stable, reduce the intensity of sunlight, and prevent the effect of mosquitoes and flies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

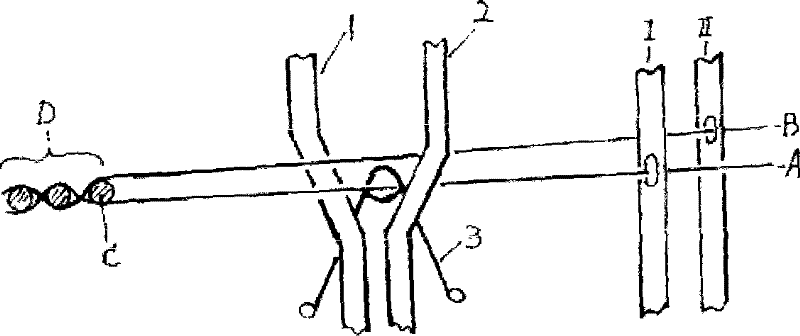

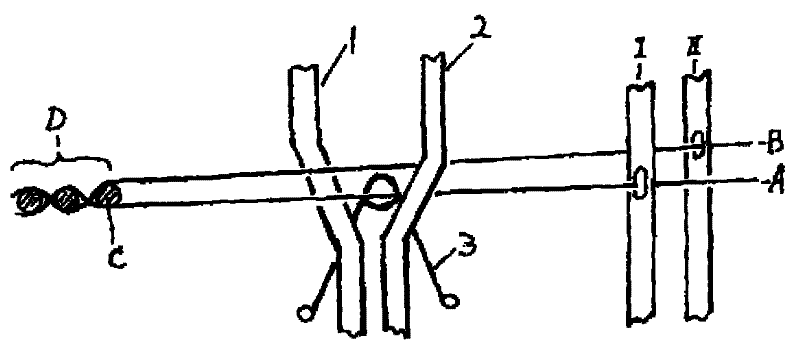

[0032] A coated polyester industrial yarn skein structure sunshade net and its forming method, using PVC-coated polyester industrial yarn as raw material, using 1 twist 1 or 1 twist 2 (that is, the arrangement ratio of twist warp and ground warp is 1:1 or 1:2) yarn weave and skein structure, which is woven into a decorative fabric sunshade net on a loom with a dobby open semi-heald skein lifting device. Utilizing the feature that the melting point of the PVC coating agent is lower than that of polyester industrial yarn (polyester), the PVC-coated polyester industrial yarn is a sheath formed with high-strength polyester yarn industrial bundles as the core layer and PVC coating glue as the skin layer. Core structure composite monofilament. Adding Nanoscale ZiO to Coating Adhesive 2 Anti-ultraviolet anti-aging agent, phosphorus flame retardant or eco-safe insect repellant. The nanoscale ZiO 2 The anti-ultraviolet and anti-aging agent is commercially available active nano-zinc ...

Embodiment 2

[0037] According to actual needs, this embodiment can adopt one or more color coating composite silk weave skein structure sunshade nets and forming methods thereof, adopting 1 twist 3 or 1 twist 5 (the arrangement ratio of skein warp and ground warp is 1:3) Or 1:5) yarn weave skein structure, on the loom of the dobby open semi-heald skein heald lifting device, weave into a decorative fabric sunshade net with rib pattern mesh. The coated polyester industrial yarn is a composite monofilament with a skin-core structure formed by using polypropylene yarn as the core layer and polyurethane coating glue as the skin layer. Adding Nanoscale ZiO to Coating Adhesive 2 Anti-ultraviolet anti-aging agent, phosphorus flame retardant. The nanoscale ZiO 2 The anti-ultraviolet and anti-aging agent is commercially available active nano-zinc oxide, with a zinc content of 95% and above. Described phosphorus flame retardant is commercially available ammonium polyphosphate, molecular formula is...

Embodiment 3

[0043] In this embodiment, according to actual needs, the sunshade net and its forming method woven by using colored coated composite yarn and one or more yarn structures or skein structures, and the coated polyester industrial yarn uses nylon yarn as the core layer, a skin-core structure composite monofilament formed with polyethylene coating glue as the skin layer. Adding Nanoscale ZiO to Coating Adhesive 2 Anti-ultraviolet anti-aging agent, ecological safety insect repellant. The nanoscale ZiO 2 The anti-ultraviolet and anti-aging agent is commercially available active nano-zinc oxide, with a zinc content of 95% and above. The ecologically safe insect repellent is BIO-X natural insect repellent, which is a pure natural insect repellent extracted from plants such as edible peppers and garlic.

[0044] Divide the warp yarns into M group and N group. The M group does not pass through the twisted heddle, but only passes through the ground heddle to weave the plain weave; whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com