Shearing device of round reversely-wrapped towel knitting machine

A technology for knitting machines and towels, which is applied in knitting, textiles, papermaking, and cut pile loops. It can solve the problems of long-term use, blade wear, and increased production costs. It achieves simple structure, reduced loss, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

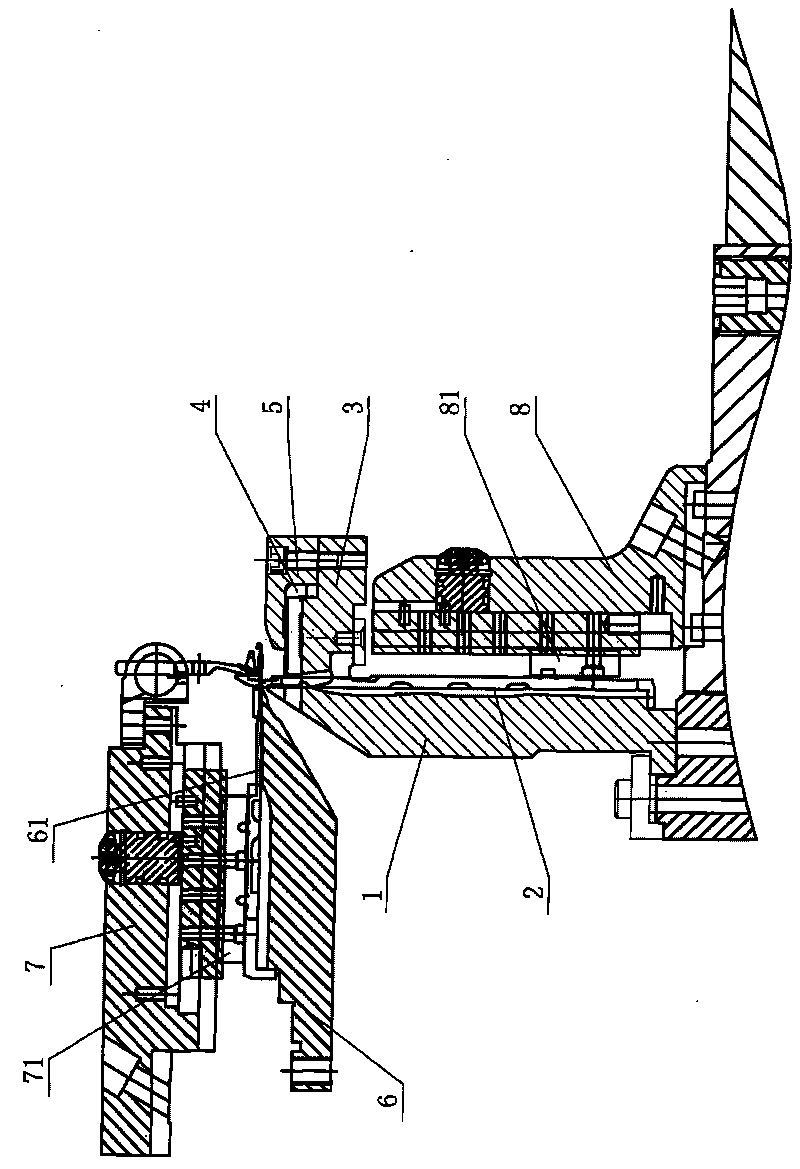

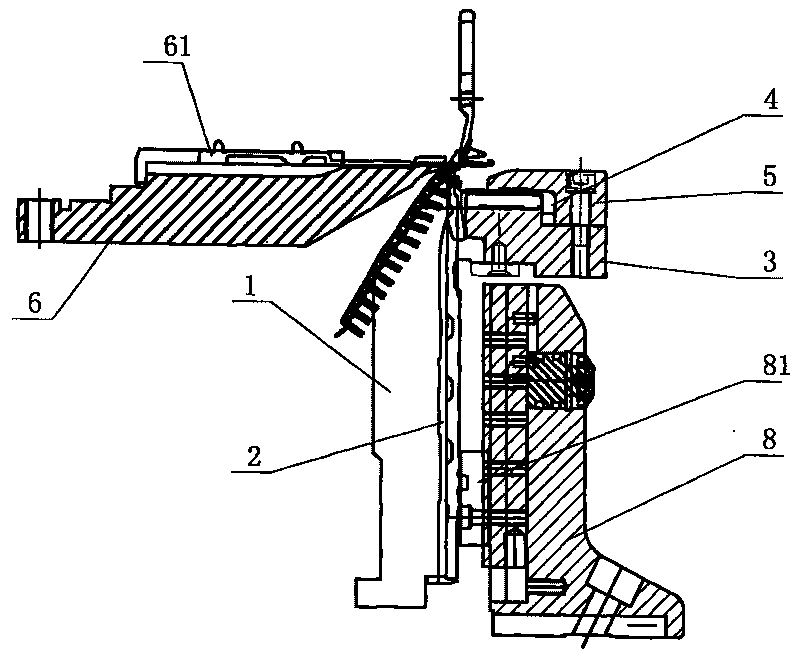

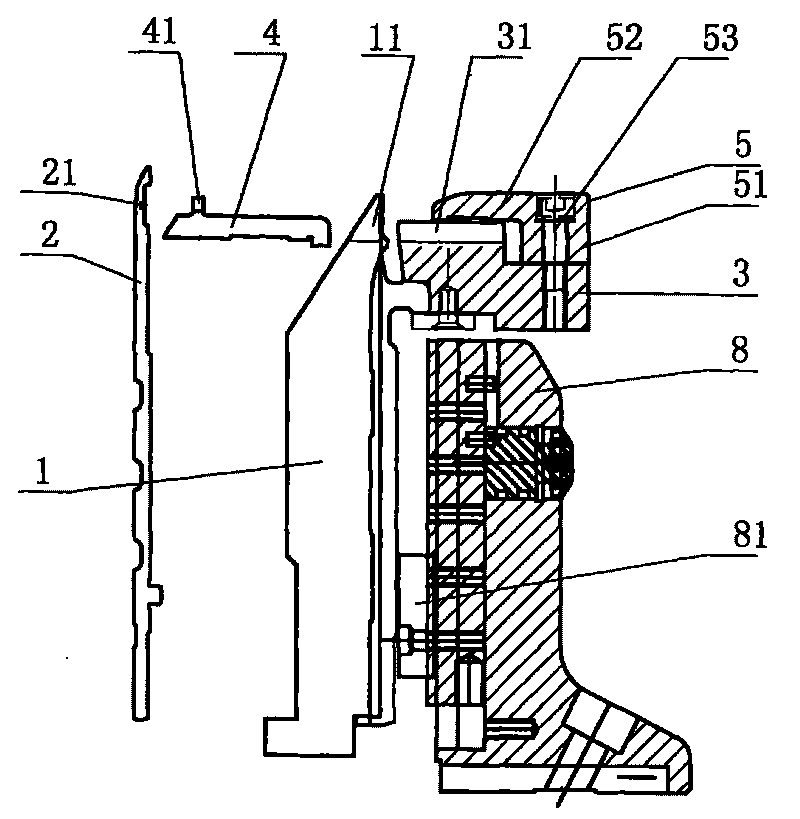

[0029] See figure 1 , 2 , 3, 4, the present invention is used in the circular turn-up towel knitting machine, and this knitting machine comprises: Lower needle cylinder 1, upper needle cylinder 6, upper horse seat 7 and lower horse seat 8. Wherein the side of following needle cylinder 1 is vertically installed with some lower loop hook yarn cutters 2 that can move up and down, and this lower loop hook yarn cutter 2 is driven by the lower triangle 81 on its side to realize moving up and down. Described lower triangle 81 is installed on the side of dismounting seat 8.

[0030] The upper end surface of the upper needle cylinder 6 is horizontally equipped with an upper knitting needle 61 corresponding to the lower knitting hook knife 2, and the upper knitting needle 61 is driven by the upper triangle 71 on its upper end to move left and right. This upper triangle 81 is installed on the lower end of the horse seat 7 . The upper knitting needle 61 and the lower loop-forming hook ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com