Dual-working condition heat pump cold hot water machine unit of parallel evaporator

A technology of cold and hot water units and evaporators, which is applied to compressors with multiple evaporators, refrigerators, refrigeration components, etc., and can solve the problem of increased exergy loss coefficient, unsuitable household independent cold and heat source systems, Complicated piping system and other problems to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

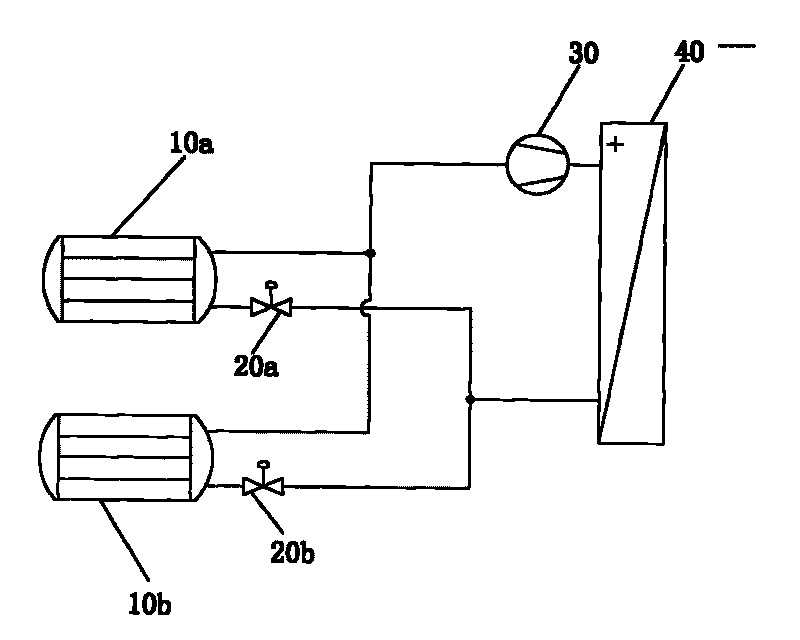

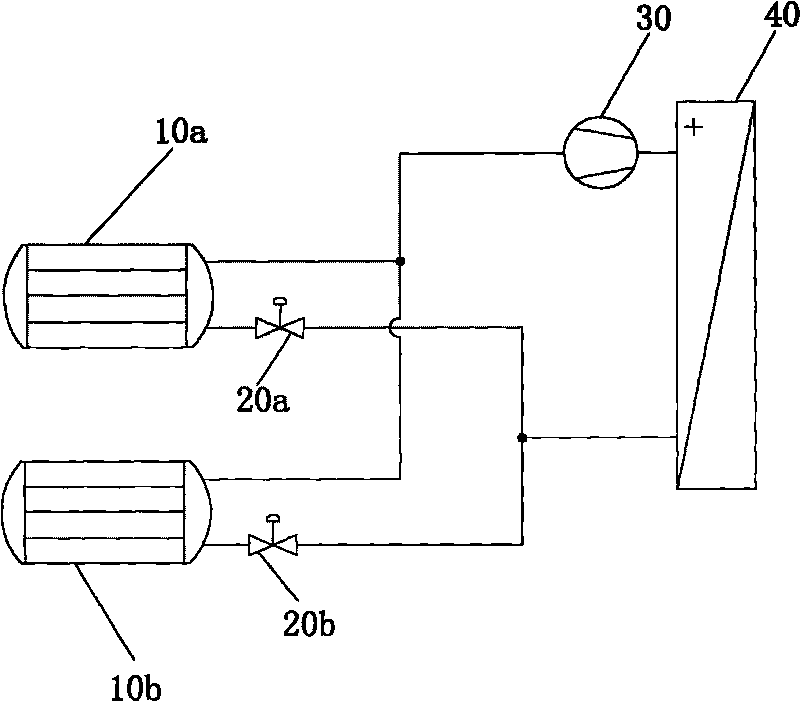

[0012] refer to figure 1 , the present invention includes a circulation loop composed of a compressor 30, a condenser 40, a first evaporator 10a, a second evaporator 10b, a first throttle valve 20a and a second throttle valve 20b, the first evaporator 10a and the second evaporator The second evaporator 10b is connected together with the compressor 30 and the condenser 40 in parallel; a first throttle valve 20a is arranged between the first evaporator 10a and the condenser 40, and a first throttle valve 20a is arranged between the second evaporator 10b and the condenser 40. A second throttle valve 20b is also arranged therebetween, and the entire circulation circuit is controlled by the first throttle valve 20a and the second throttle valve 20b. Wherein, the first throttle valve 20a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com