Conveying device capable of stopping

A conveying device and chain technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of poor reliability, easy aging of air pipes, and high cost of pneumatic components, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

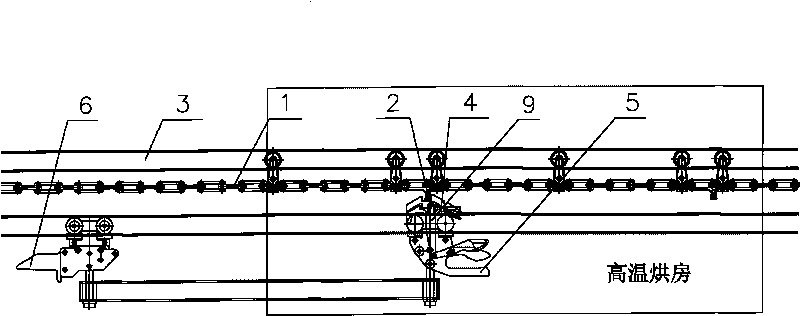

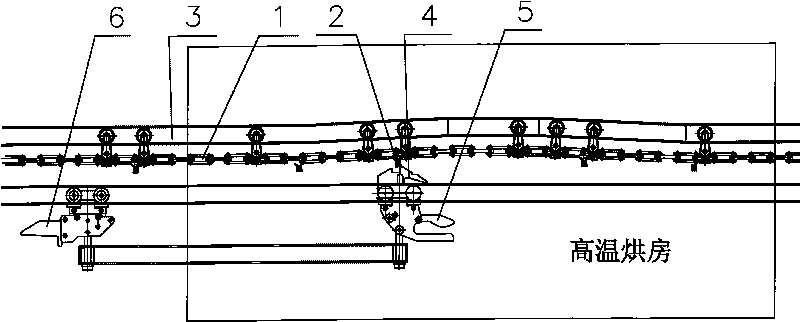

[0013] Such as figure 2 As shown, when the trolley 17 enters the drying room, since the traction rail 3 of the chain 1 is lifted, the chain 1 and the push head 2 are lifted for a certain distance along the traction rail 3 (the height is greater than the depth of the groove of the lifting claw 4) , the lifting claw 4 of the trolley is disengaged from the push head 2 of the chain 1, and the trolley I 7 stops running.

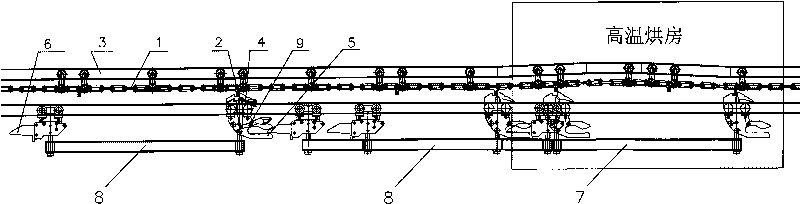

[0014] Such as image 3 Shown, the working process schematic diagram of the present invention:

[0015] After the stopped trolley I 7 dries in the drying room for a period of time, the stopper outside the drying room is opened, and the trolley II8 moves forward, and the trolley II 8 drives the trolley I 7 to move forward until the trolley II 8 runs to the rail lifting place . In the process of trolley II 8 pushing trolley I 7 to run, the front shovel 5 of trolley II 8 is inserted into the tail plate 6 of trolley I 7. Since the traction rail 3 is lifted for a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com