Pneumatic valve locking plate dismounting device

A valve lock plate, pneumatic technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced maintenance efficiency, inconvenient production, time-consuming and laborious, etc., to achieve precise operation, high work efficiency, and reduce compression The effect of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

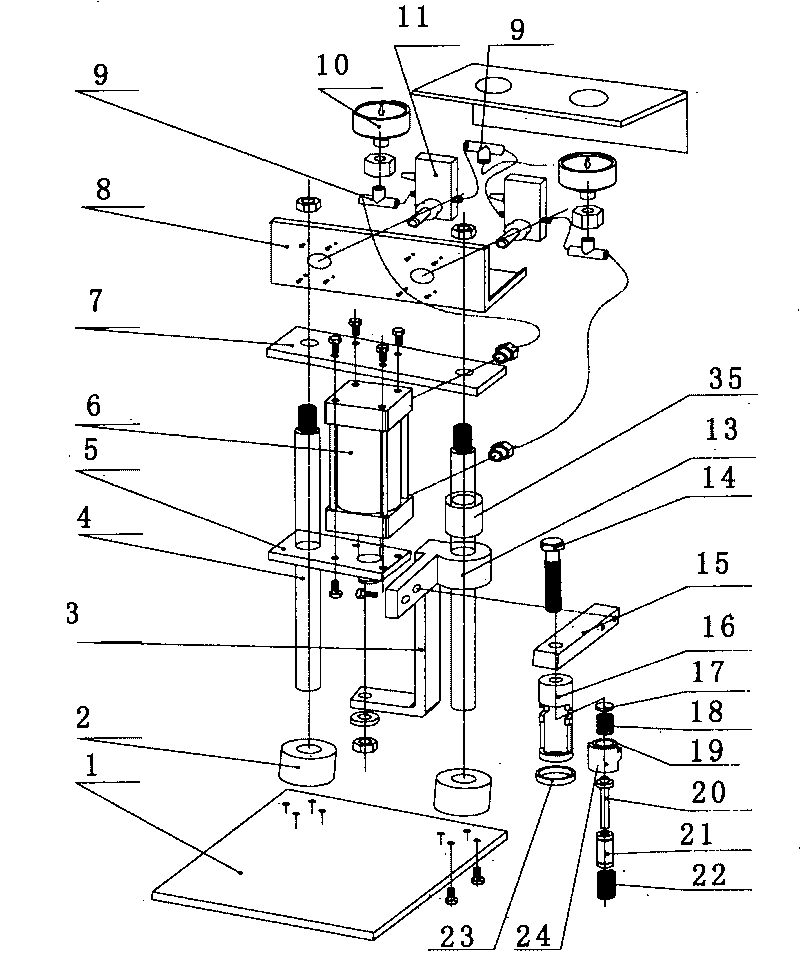

[0033] Such as figure 1 , Figure 4 , Figure 6 and Figure 8 A pneumatic valve lock plate remover with a bolt-type lock plate placer is shown, including a base plate 1, a column 4 fixed on the base plate, a column connecting block 2, a cylinder 6, a connecting rod 3, and a movable frame 13 1. Lock plate dismounting mechanism and valve head gasket, lock plate dismounting mechanism includes valve spring compressor 16, valve spring compressor force arm 15 and lock plate placer 26; The upper end of the cylinder 6 is fixed on the upper fixing plate 7, The lower end of the cylinder 6 is fixed on the lower fixed plate 5, the lower fixed plate 5 is movably socketed on a column 4, the piston of the cylinder 6 passes through the lower fixed plate 5 and the connecting rod 3 is fixedly connected to the other end of the connecting rod 3 and the movable frame 13 Fixedly connected, the movable frame 13 is movably socketed on another column 4 through a sliding sleeve 35, the valve spring ...

Embodiment 2

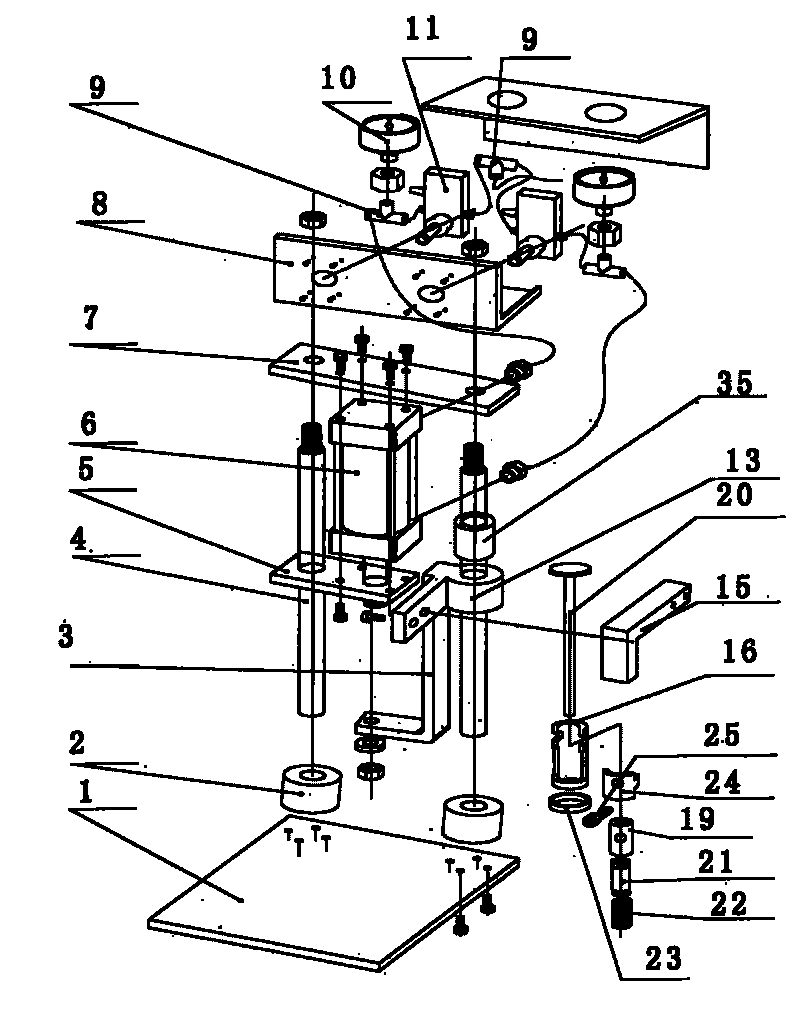

[0035] Such as figure 2 , Figure 5 , Figure 7 and Figure 8 A pneumatic valve lock plate remover with a fixed lock plate placer is shown, including a base plate 1, a column 4 fixed on the base plate, a column connecting block 2, a cylinder 6, a connecting rod 3, and a movable frame 13 1. Lock plate dismounting mechanism and valve head gasket. The lock plate dismounting mechanism includes valve spring compressor 16, valve spring compressor arm 15 and lock plate placer 26; the upper end of cylinder 6 is fixed on the upper fixing plate 7, and the cylinder 6 The lower end is fixed on the lower fixed plate 5, the lower fixed plate 5 is movably socketed on a column 4, the piston of the cylinder 6 passes through the lower fixed plate 5 and is fixedly connected with the connecting rod 3, and the other end of the connecting rod 3 is fixed with the movable frame 13 connection, the movable frame 13 is movably socketed on another column 4 through the sliding sleeve 35, the movable f...

Embodiment 3

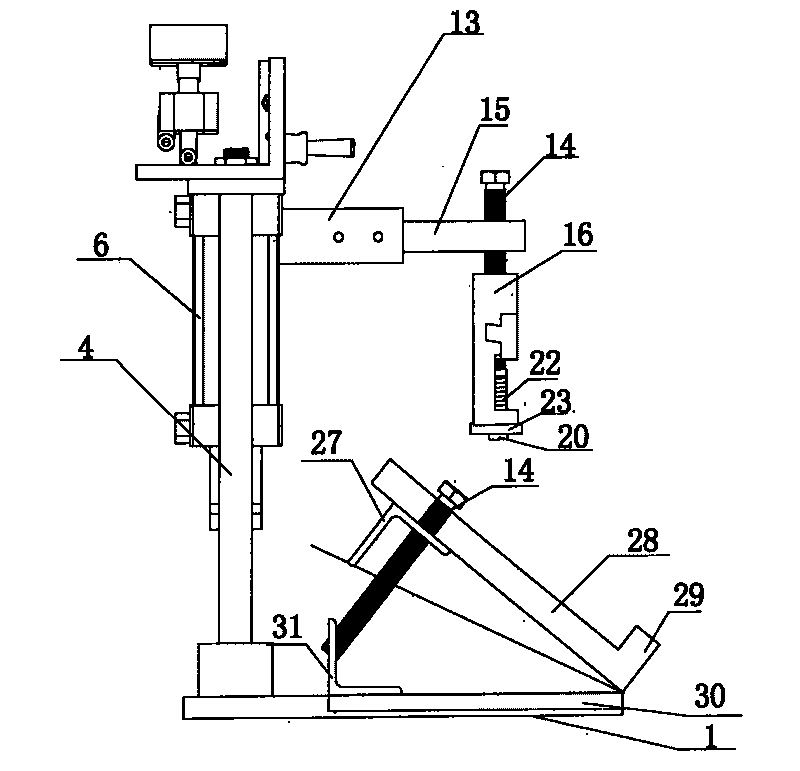

[0037] Such as image 3 and Figure 8 As shown, the pneumatic valve lock plate remover also includes a cylinder head angle adjustment bracket placed on the bottom plate 1, and the cylinder head angle adjustment bracket includes an upper adjustment plate 28, a lower adjustment plate 30, an upper support angle iron 27, a lower Support angle iron 31, one end of upper adjustment plate 28 is provided with baffle plate 29, the upper adjustment plate 28 and lower adjustment plate 30 are hinged at one end of baffle plate 29, and the upper support angle iron 27 is fixed on the lower side of the other end of upper adjustment plate 28 , the lower support angle iron 31 is fixed on the upper side of the opposite end of the hinged end of the lower adjustment plate 30, and the upper adjustment plate 28 is fixed on one end of the upper support angle iron 27 to be provided with 1-3 adjustment bolts 14; the valve head pad is placed On the upper adjustment plate 28 of the cylinder head angle ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com