Method and device for coating film to hang tag of black card clothes

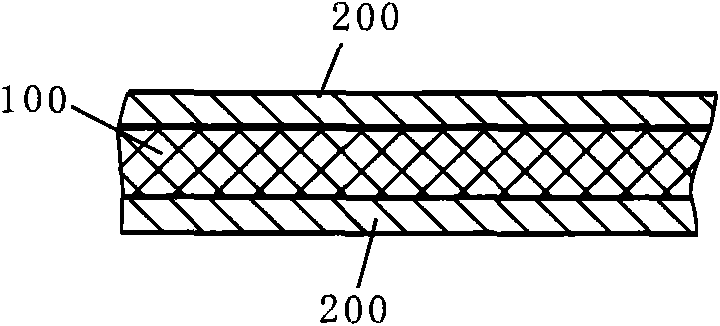

A black card and clothing technology is applied in the field of laminating methods and devices for black card clothing hangtags, which can solve the problems of damage to, detachment of the laminating machine, affecting the quality of black card clothing hangtags, etc., and achieve the effect of improving quality and overcoming white light spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

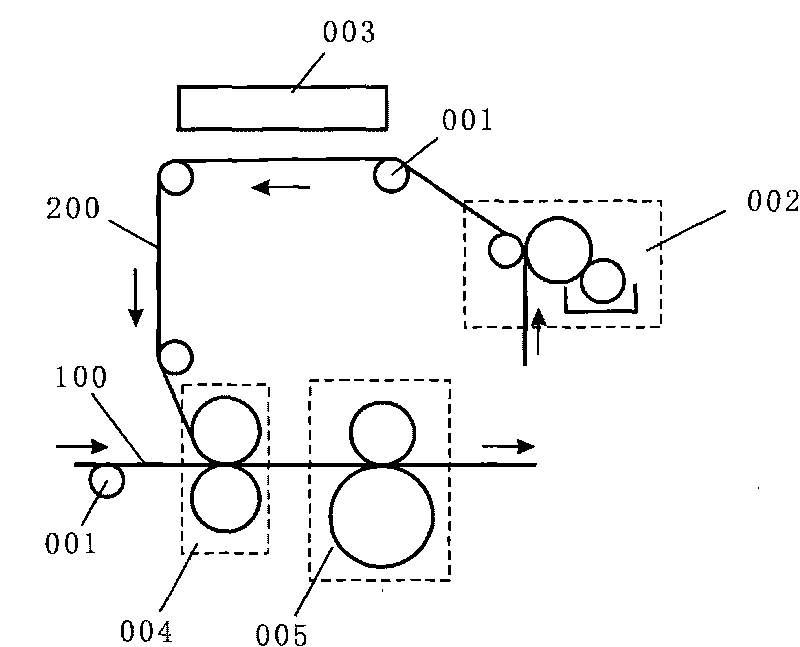

[0021] Such as image 3 As shown, the black card clothing tag laminating device of the present invention is connected with a gluing device 002, a gluing device 003, a rolling device 004 and a calender head 005 in sequence through a transfer roller 001.

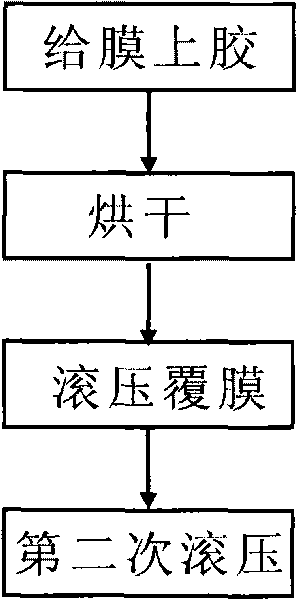

[0022] Such as figure 2 and combine image 3 , the black card garment hang tag coating method of the present invention, its steps are:

[0023] 1. Apply glue to the surface of the plastic film, the thickness of the glue is 0.33kg / cm 2 ; Such glue thickness makes the adhesion of plastic film and black cardboard stronger.

[0024] 2. Dry the glue on the plastic film.

[0025] 3. Use a pressure of 15MPa to roll the plastic film on the black cardboard; the speed of the roller used for rolling is set to 80-100rpm;

[0026] 4. Use the calender head to roll the black cardboard covered with plastic film for the second rolling, the pressure of the second rolling is 25-30MPa.

[0027] Using the above-mentioned method and device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com