Construction method for large equipment hoisting tail sliding rail

A large-scale equipment and construction method technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of traction that cannot meet the requirements, large traction, large friction coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

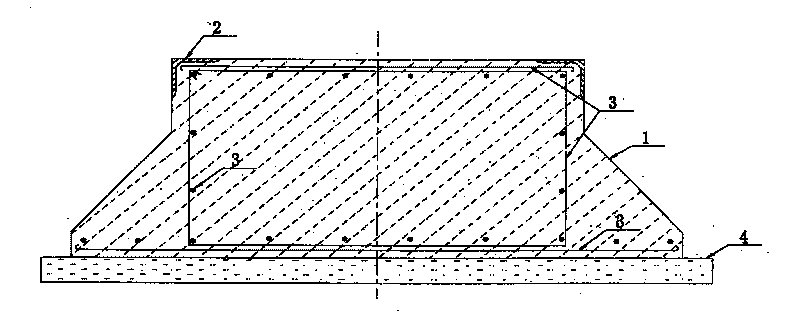

[0013] Level the bottom surface and then lay the concrete cushion 4, level the top of the concrete cushion 4 and set the reinforcement mesh 3, then pour concrete, and set the embedded angle steel 2 on both sides of the concrete cap 1 before the concrete cap 1 is poured.

Embodiment 2

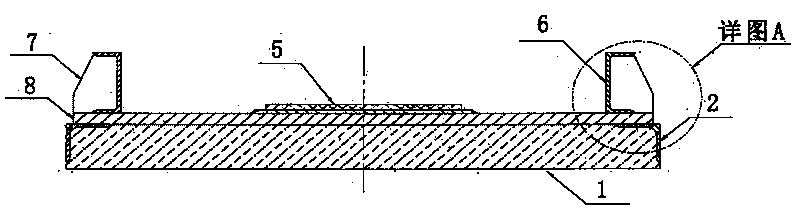

[0015] A track support base plate 8 is arranged above the concrete cap 1, and both sides of the track support base plate (8) are welded with pre-embedded angle steel (2) as a whole, and are fixed on the concrete cap.

Embodiment 3

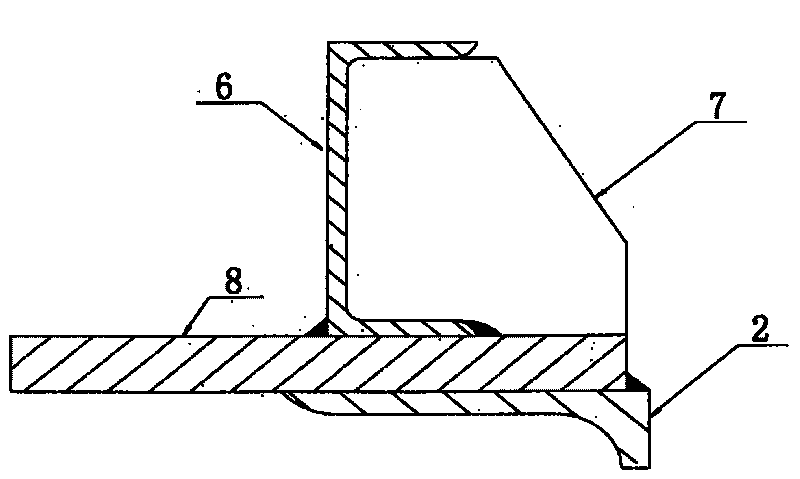

[0017] The channel steel (6) is welded together with the track support base plate (8), and at least one stiffener plate (7) is welded on the outer side of the channel steel (6) at intervals;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com