Method for lifting shipping caisson by capsule trolley

A caisson and trolley technology, applied in caisson, construction, infrastructure engineering and other directions, can solve the problems of complex procedures, many hidden safety hazards, low shipping efficiency, etc., and achieve the effects of avoiding pollution, safe shipping process, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

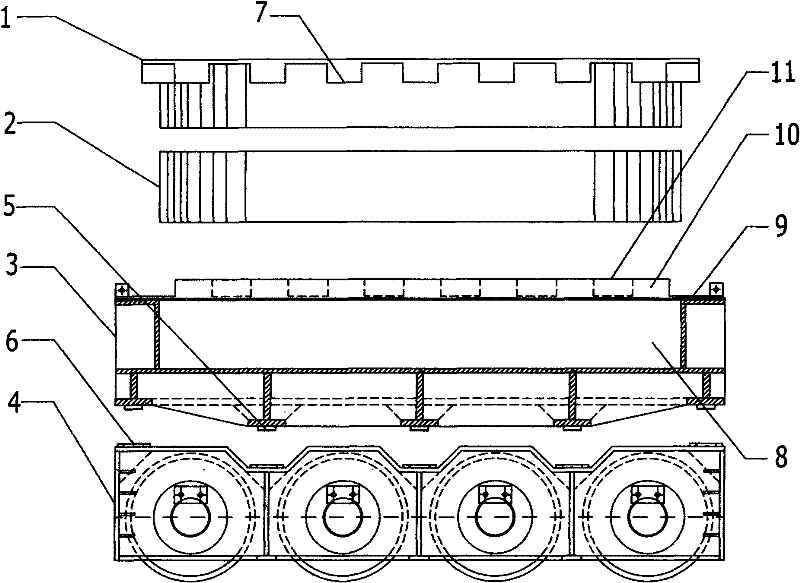

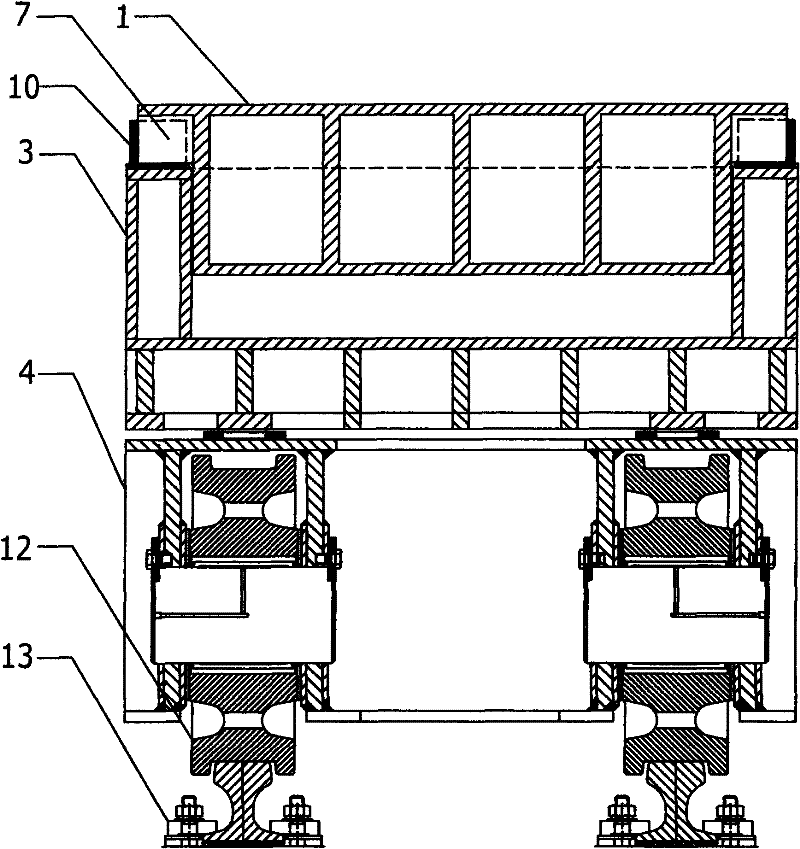

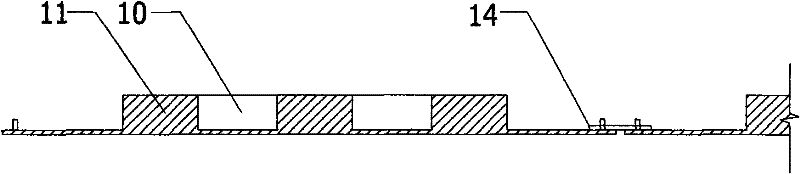

[0016] Such as Figure 1 to Figure 3 The schematic diagram of the trolley structure of the present invention is a capsule trolley for transporting caissons, which is composed of a plurality of trolley units. Each trolley unit includes a base frame 4 installed on the track 13, and is installed on The jacking support box 3 on the frame 4, the jacking capsule 2 arranged in the box, and the caisson lifting plate 1 installed above the jacking support box 3 and can be lifted by the jacking capsule 2, the The jacking supporting box body 3 is provided with a pipeline, and the pipeline communicates with the pipeline mouth of the jacking capsule 2 inside the box body. The base frame rests on rails 13 via wheel rails 12 .

[0017] The upper surface of the base frame 4 is provided with a groove with a trapezoidal cross section, and the surface of the groove is provided with a circular embedding hole 6, and the lower surface of the jacking support box is provided with a matching protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com