Refrigerator door body

A refrigerator door body and door liner technology, applied in lighting and heating equipment, household appliances, household refrigeration equipment, etc. Implementation and other issues, to achieve the effect of reducing material costs, simple and easy implementation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

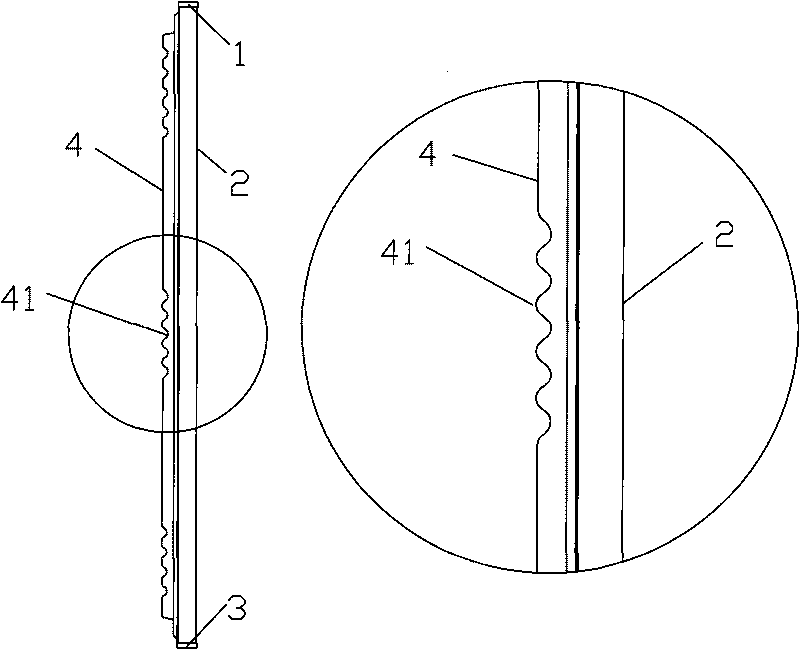

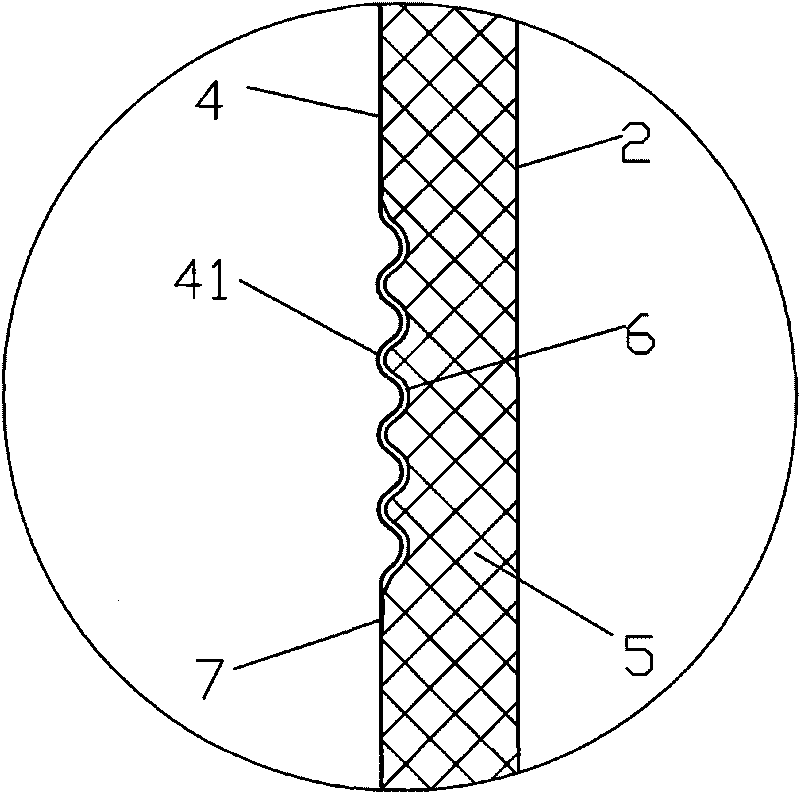

[0022] see figure 1 , figure 2 The door body of the refrigerator is composed of an upper end cover 1, a door panel 2, a lower end cover 3, and a door liner 4, etc. The foam material is injected in the middle, and after the foam material is foamed, matured and solidified, a heat-insulating foam layer 5 is formed; the foam material combines the above The parts are bonded together to form a rigid whole - the refrigerator door.

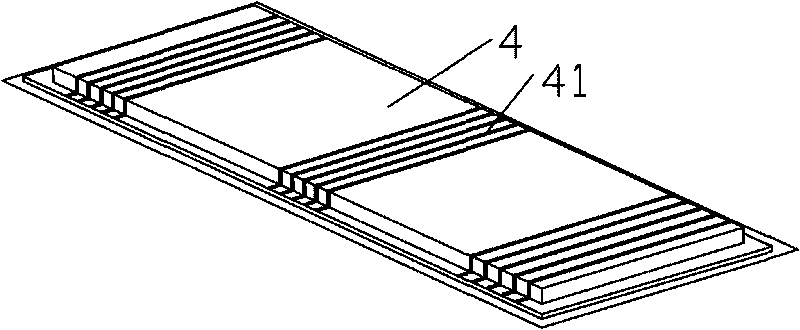

[0023] see image 3 , The upper, middle and lower parts of the door liner 4 are provided with several grooves or flanges 41 . The groove or flange 41 extends from one side of the door liner 4 to the other side of the door liner 4 , and passes through the steps of the door liner 4 . The specific number of grooves or flanges 41 is determined by the size of the refrigerator door; the larger the refrigerator door, the greater the degree of deformation, and the required number of grooves or flanges 41 also increases accordingly.

[0024] see figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com