Total run-out comprehensive measuring instrument

A checker and full runout technology, applied in the direction of instruments, measuring devices, electric/magnetic profile/curvature measurement, etc., can solve the problem of rarely marking full runout tolerance items, achieve high energy efficiency ratio, reduce errors, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

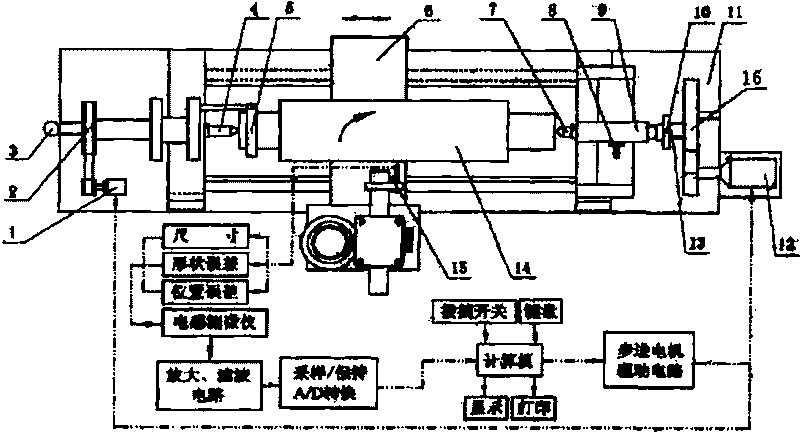

[0017] like figure 1 As shown, the full run-out comprehensive inspection of the present invention includes a base part, a head frame part, a measuring slide mechanism, a measuring device, an axial and radial measuring position transformation mechanism, a control circuit, and a computer.

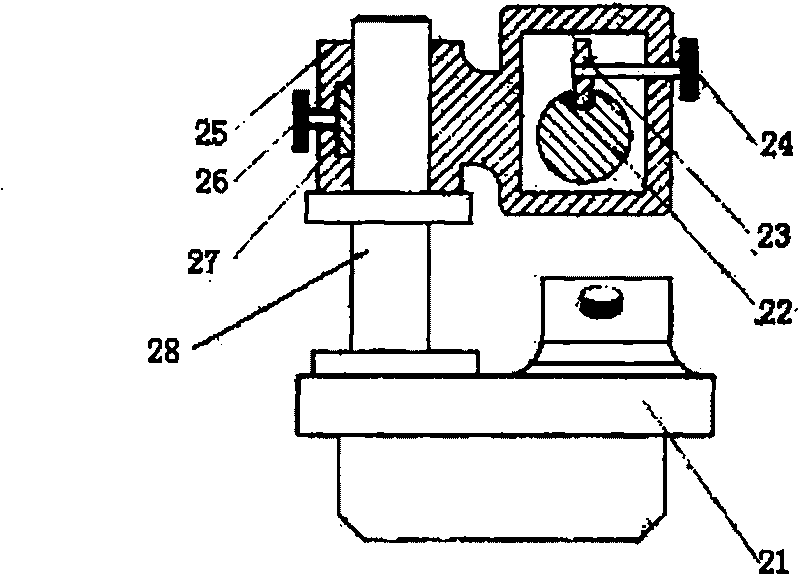

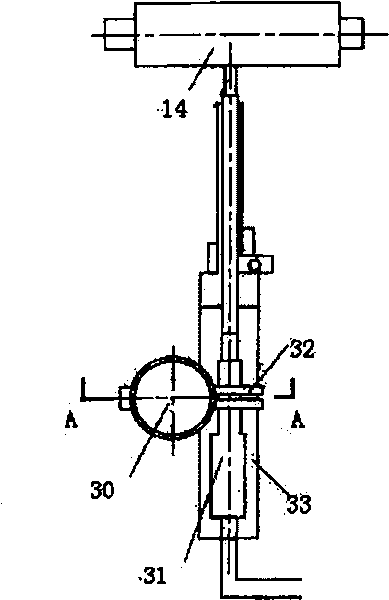

[0018] The left and right ends of the base 11 are respectively equipped with a head frame component and a right top device composed of a right top 7, a locking mechanism 8, a right top seat 9 and a hand wheel 10, and a measuring slide mechanism 6 for lateral movement is installed on the middle , a measuring slide plate transmission mechanism is installed between the measuring slide plate mechanism 6 and the base part, a measuring device 15 is installed on the measuring slide plate mechanism 6, and the measuring device 15 is provided with an axial and radial measuring position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com