Constant-voltage electric brush device of motor

A piezoelectric and brush technology, used in electromechanical devices, electrical components, etc., can solve problems such as reduced pressure on brush collector rings, wear of brushes and collector rings, and poor contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

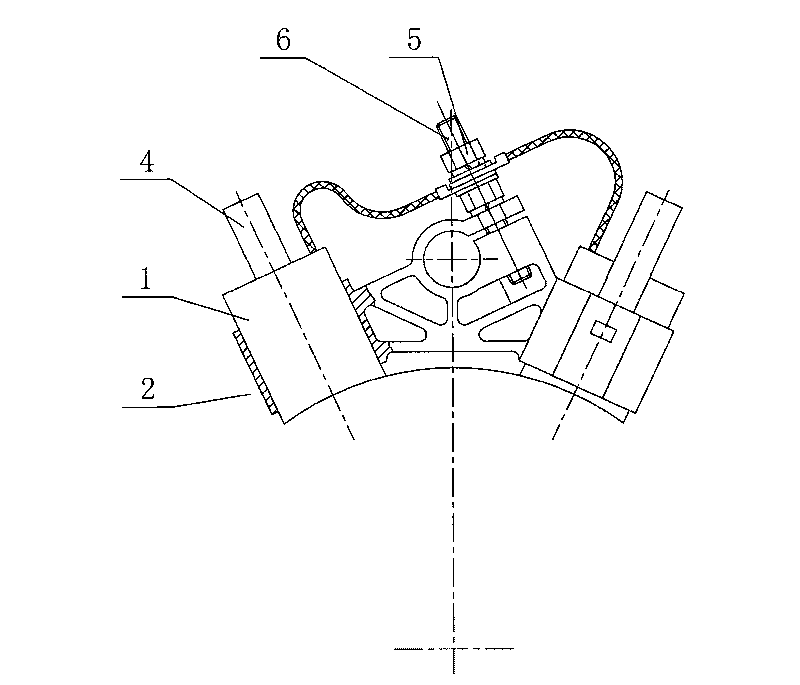

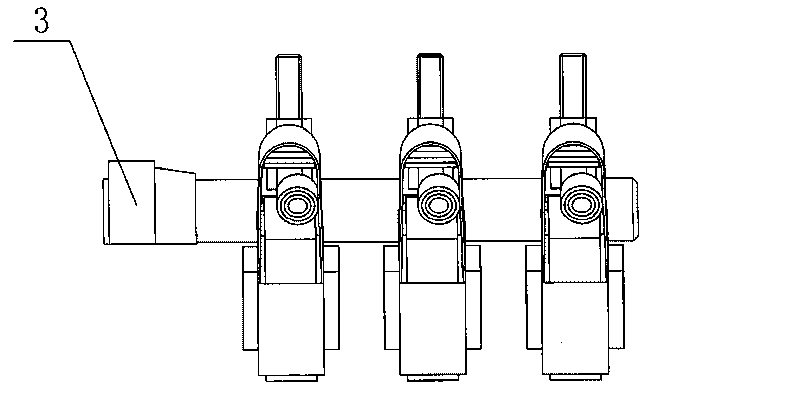

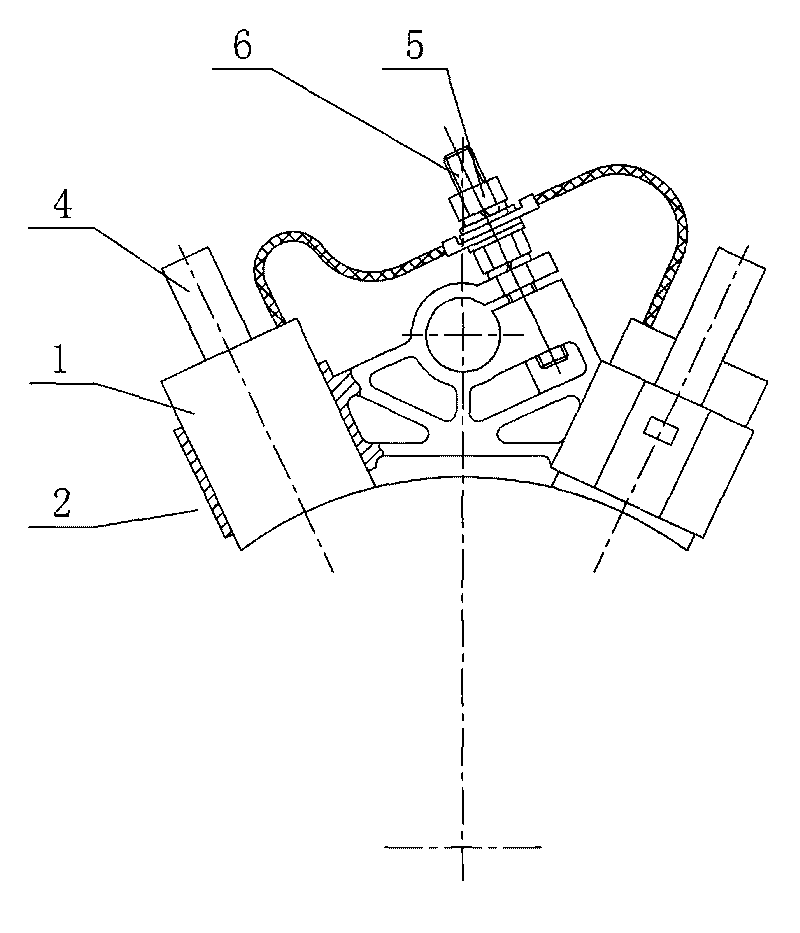

[0014] Such as Figure 1-2 As shown, the constant voltage brush device of the motor according to the present invention includes a brush box 2, a brush 1 installed inside the brush box 2, a brush bar 3 passing through the brush box 2, and the brush box 2 is fixed on the brush bar 3 and tightened by the nut 5 and the set screw 6, a constant pressure spring 4 is installed at the rear of the brush 1, and the constant pressure spring 4 is a rigid spring.

[0015] The constant pressure spring 4 can support the contact between the brush 1 and the collector ring, and since the constant pressure spring 4 is a rigid spring, the radius of curvature and the number of turns of the constant pressure spring can meet the rigidity requirements, especially after the brush is worn out, the electric The brush produces a small axial displacement, and the pressure of the constant pressure spring will only change slightly at this time, but the pressure is still within the allowable pressure control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com