Correlated color temperature and color rendering index self-calibration circuit of LED light source consisting of light of multiple colors

A technology of LED light source and correlated color temperature, applied in the direction of light source, electric light source, electric light circuit layout, etc., can solve complex problems, achieve the effect of eliminating self-calibration errors, easy to use, and improving color rendering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

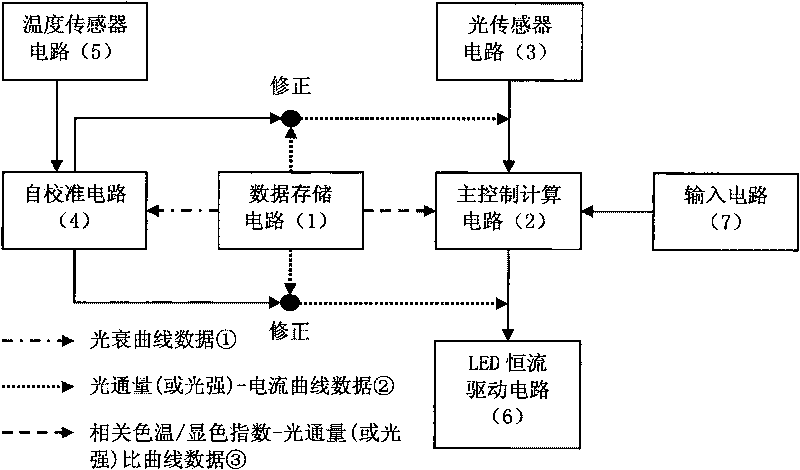

[0035] Such as Figure 4 As shown, a correlated color temperature self-calibration circuit and method of a "white LED+red LED" light source, since the light source contains two kinds of LEDs, white light and red light, the circuit includes two sets of constant current drive circuits 1 and 2, respectively driving white light LEDs and red LEDs can accurately control their luminous flux (or light intensity). The composition of other parts of the circuit is the same as the content of the above invention.

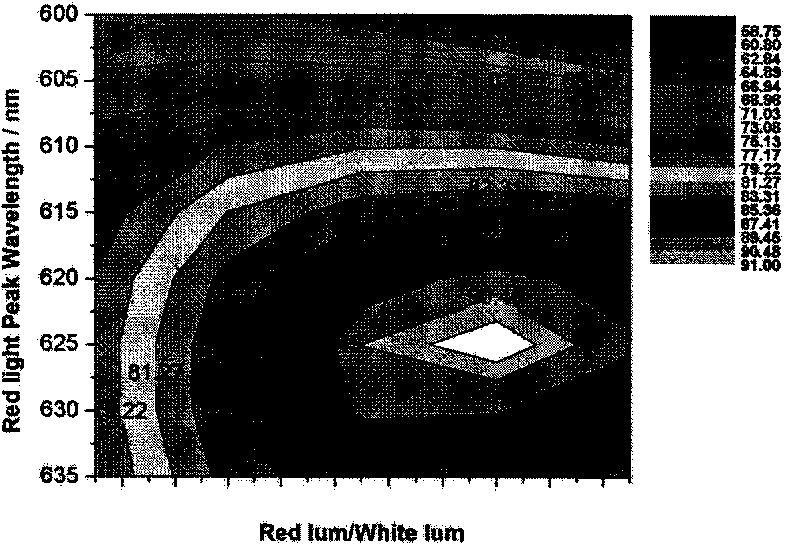

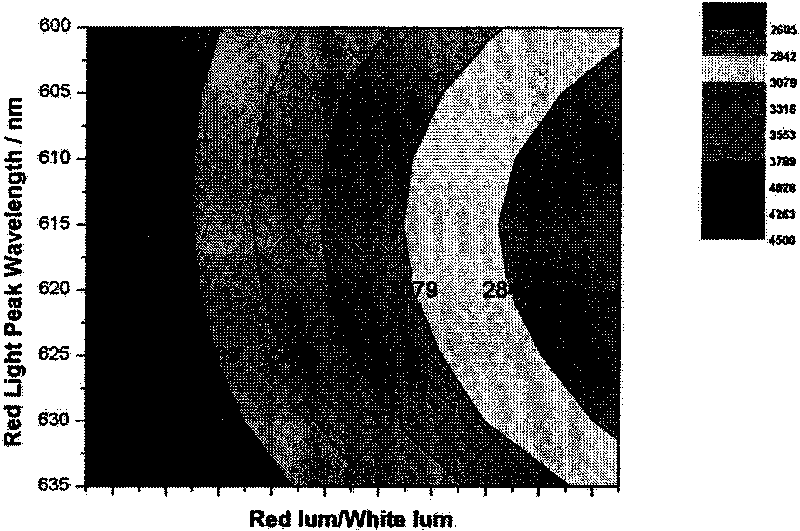

[0036] First of all, as described in the above summary of the invention, the main control calculation circuit establishes a conversion database between the feedback signal of the light sensor and the luminous flux (or light intensity) of the white light, and the luminous flux (or light intensity) emitted by the white light LED can be calculated through the response signal of the light sensor circuit. powerful). The data storage circuit transmits the correlated color temperatur...

Embodiment 2

[0039] A high color rendering maintenance circuit for a "white LED + red LED" light source, the system configuration and adjustment principle are similar to those in Embodiment 1. The difference is that the data storage circuit transmits the color rendering index-red and white light luminous flux (or light intensity) ratio curve data to the main control calculation circuit, and the main control calculation circuit finds out the required red light luminous flux (or light intensity) according to the highest color rendering index point. optimal ratio of light intensity).

[0040] The holding circuit is suitable for all kinds of white LEDs on the market. For white LEDs with different packages and models, you only need to choose a suitable red LED to make a white LED lamp with a high color rendering index, which is convenient for use in Occasions with high requirements for light source color rendering.

Embodiment 3

[0042] Such as Figure 5 As shown, a "white LED + red LED + green LED" light source with adjustable correlated color temperature and high color rendering self-calibration circuit. The above two implementation examples can only self-calibrate the correlated color temperature or color rendering index independently. If it is necessary to self-calibrate the two indicators of correlated color temperature and color rendering index at the same time, it is necessary to add an additional color to the LED light source. Therefore, this implementation example uses three sets of constant current drive circuits 1, 2 and 3 to drive white LEDs, red LEDs and green LEDs respectively, which can maintain high color rendering even when the correlated color temperature is artificially changed.

[0043] The difference from the above two implementation examples is that the data storage circuit transmits the color rendering index-luminous flux (or light intensity) ratio data group and the correlated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com