A method for preparing silicon nitride powder from sawdust

A technology of silicon nitride powder and sawdust, which is applied in the field of ceramics, can solve the problems of wide particle size distribution range, low powder purity, irregular particle shape, etc., and achieve the effect of narrow particle size distribution range, good performance and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

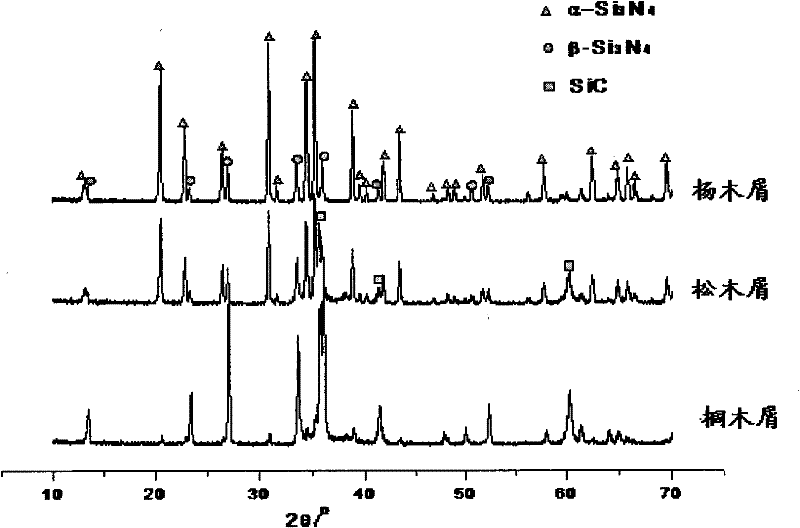

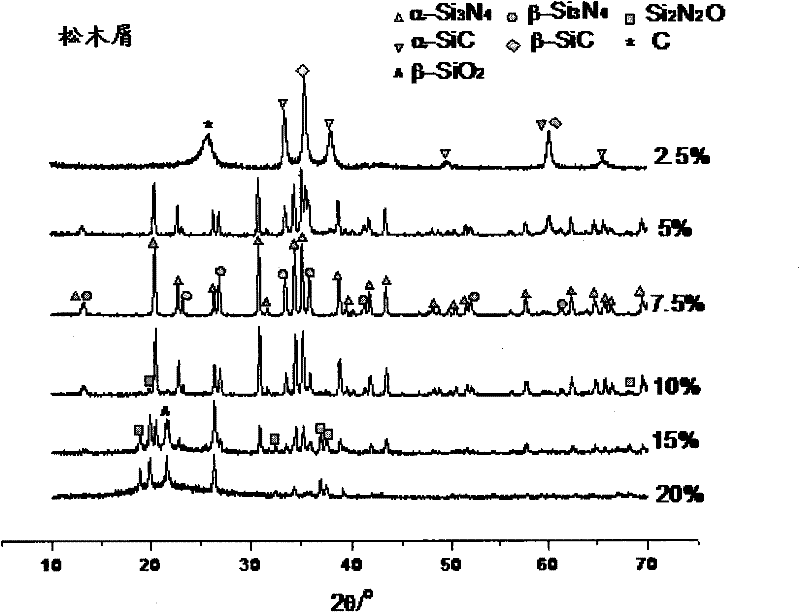

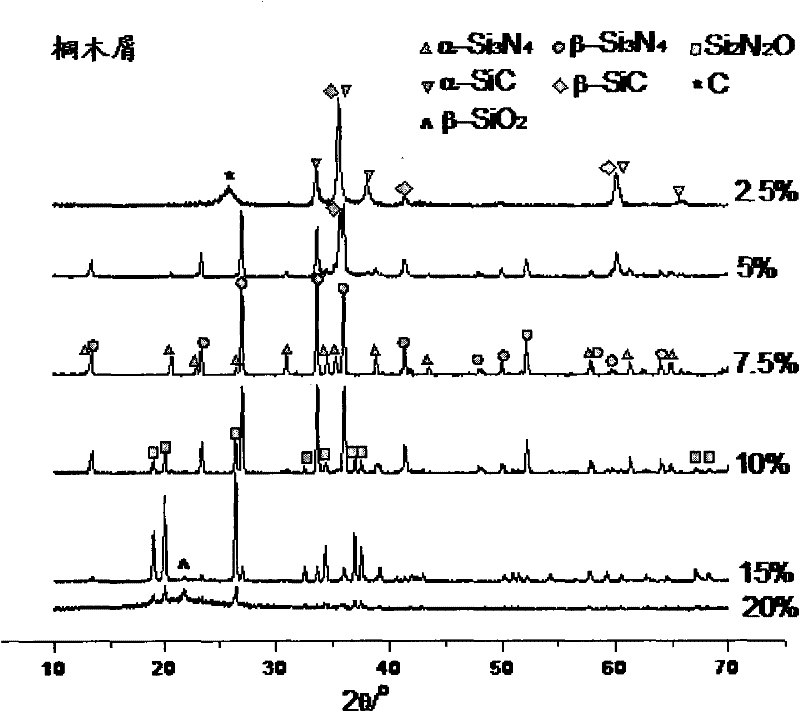

[0028] The method for preparing silicon nitride powder from sawdust according to the present invention is based on the following principles: use sawdust and silica sol as the main raw materials, make full use of the characteristics of porous sawdust, easy impregnation, carbonization at high temperature, and easy grinding of the produced powder , through the sol-gel method, inorganic substances are introduced into the wood chips, and the gel with silica as the main component is filled in the pores of the wood, so that the raw materials are mixed evenly, and then the carbothermal reduction nitriding method is selected, and the impregnated Sawdust of silica sol, in a high-temperature controlled atmosphere furnace, carbonization, carbon thermal reduction and nitriding in one step to prepare Si 3 N 4 Ceramic powder. The overall reaction formula of this carbothermal reduction nitriding reaction is:

[0029] 3SiO 2 (s)+6C(s)+2N 2 (g)==Si 3 N 4 (s)+6CO(g)

[0030] Relevant stud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com