Preserved egg cutting machine

A cutting machine, preserved egg technology, applied in metal processing and other directions, can solve problems such as inconvenience, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawings and examples.

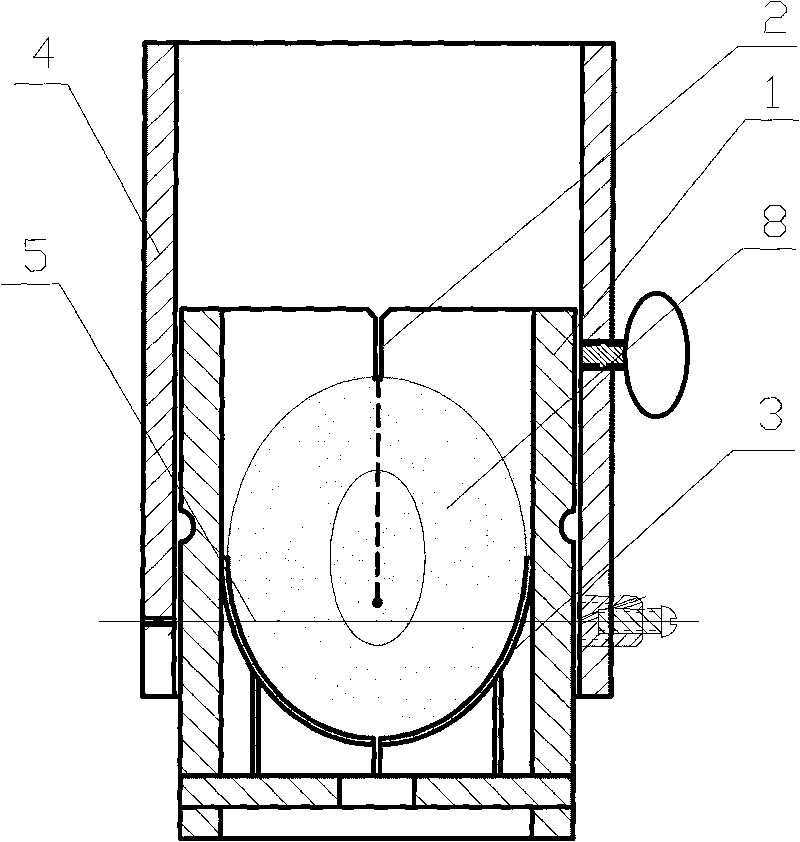

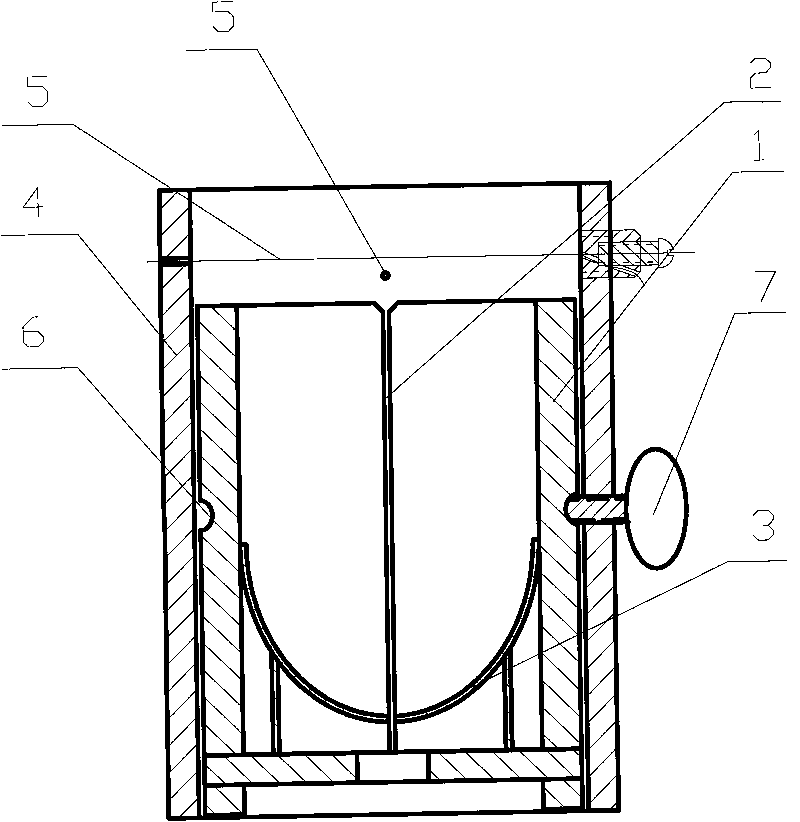

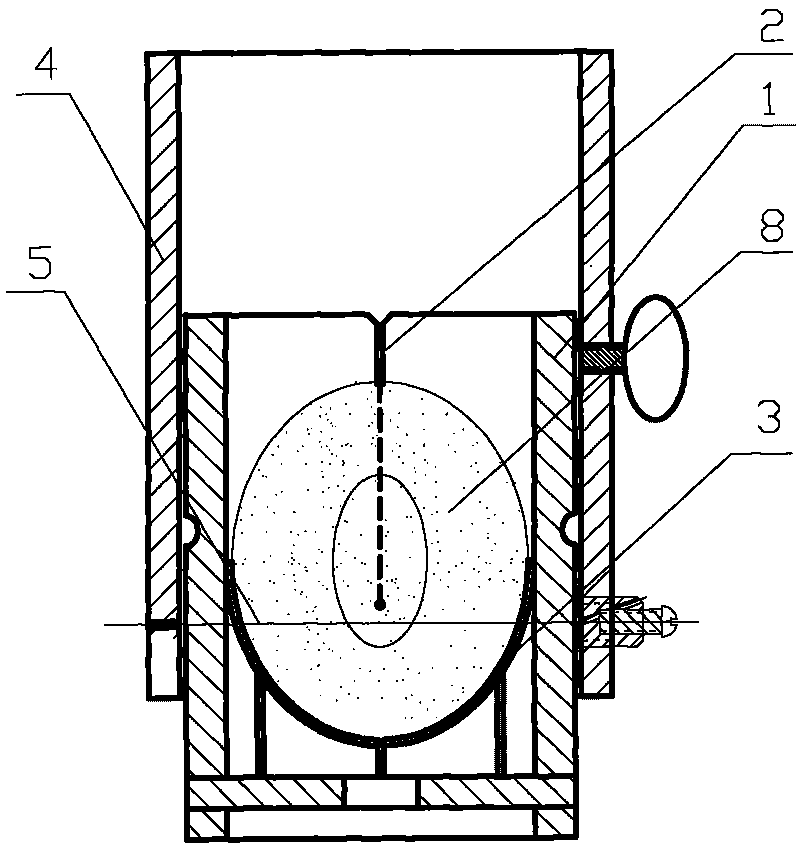

[0010] Such as figure 1 As shown, a preserved egg cutting machine includes a preserved egg holder and a secant line guide cylinder. The preserved egg holder is a cylindrical shell 1 with a sliding oval fixed seat 3 at the bottom. The shell is provided with four guides along the axial direction. Groove 2, the plane where the two opposite guide grooves are located and the plane where the other two guide grooves are located are perpendicular to each other, and the secant guide cylinder 4 is set outside the preserved egg holder. Secant 5, the two secant lines are staggered up and down by an appropriate distance along the axial direction. A groove 6 is provided on the outer wall of the housing, and a corresponding positioning pin 7 is provided on the secant guide cylinder 4 .

[0011] During operation, the preserved egg 8 after shelling and washing is first place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com