Super magnetostrictive high-speed jet valve

A giant magnetostrictive, high-speed injection technology, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of high temperature, low driving efficiency, and complex structure of giant magnetostrictive rods. The effect of miniaturization, high drive efficiency and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

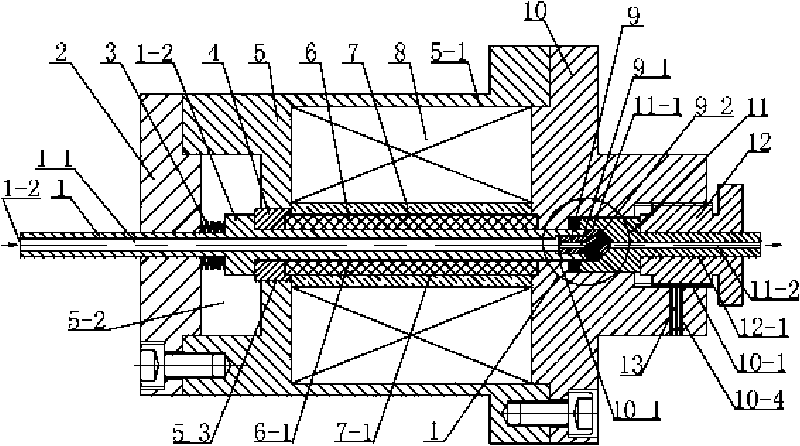

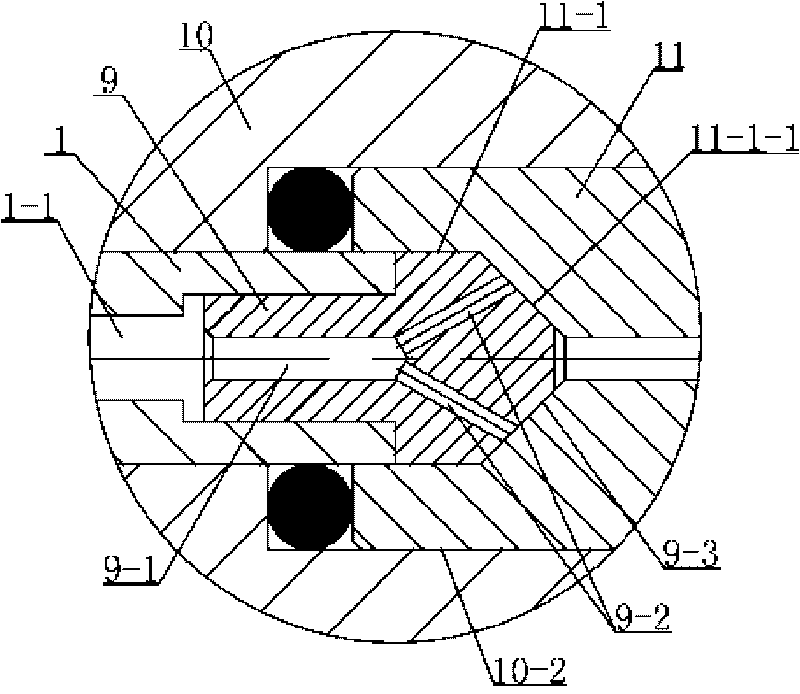

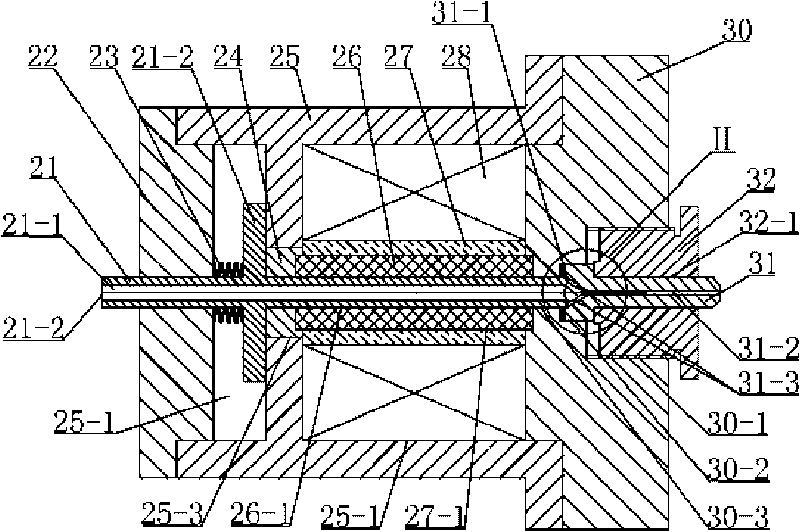

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes the first push rod 1, the first input end cover 2, the first disc spring 3, the first top block 4, the first shell 5, the first giant magnetostrictive rod 6, the first A skeleton 7, a first coil 8, a plug 9, a first output end cover 10, a first valve seat 11 and a first adjustment seat 12, and a first magnetic field cavity 5- 1. The first disc spring cavity 5-2 is provided on the input end surface of the first housing 5, the first housing center hole 5-3 is provided at the axis of the first housing 5, and the first top block 4 is set on the first In the center hole 5-3 of the casing, a first stepped hole is provided at the axis of the first output end cover 10, and the first stepped hole is respectively the first installation hole 10-1 and the second installation hole from the output end to the input end. 10-2 and the third installation hole 10-3, the fi...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 To describe this embodiment, the material of the first ejector pin 1 of this embodiment is 1Cr18Ni9Ti or Monel400, and the material of the first skeleton 7 is PEEK. 1Cr18Ni9Ti and Monel400 materials are non-magnetic, corrosion-resistant and have high mechanical strength. The first ejector rod 1 serves as an output and fluid flow path while improving the magnetic circuit so that the magnetic field lines mainly pass through the first giant magnetostrictive rod 6. The PEEK material is non-conductive. It has good magnetic and heat insulation properties, and can be precisely processed and shaped to meet the matching gap with the first giant magnetostrictive rod 6, and play the role of heat insulation, fixing and protecting materials. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 To describe this embodiment, the materials of the first jack block 4 , the first housing 5 and the first output end cover 10 in this embodiment are all made of No. 10 steel. No. 10 steel is a magnetic material, so that the first top block 4, the first shell 5, the first output end cover 10 and the first giant magnetostrictive rod 6 form a closed magnetic circuit, and the first giant magnetostrictive rod is added. 6 central magnetic field strength. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com