Method for manufacturing high-resolution optical fiber image transmission bundle

An optical fiber image beam, high-resolution technology, applied in graded-index core/clad optical fibers, clad optical fibers, bundled optical fibers, etc. problems such as low pixel quality, to achieve the effect of ensuring accuracy, ensuring pixel quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The concrete realization mode of the present invention is:

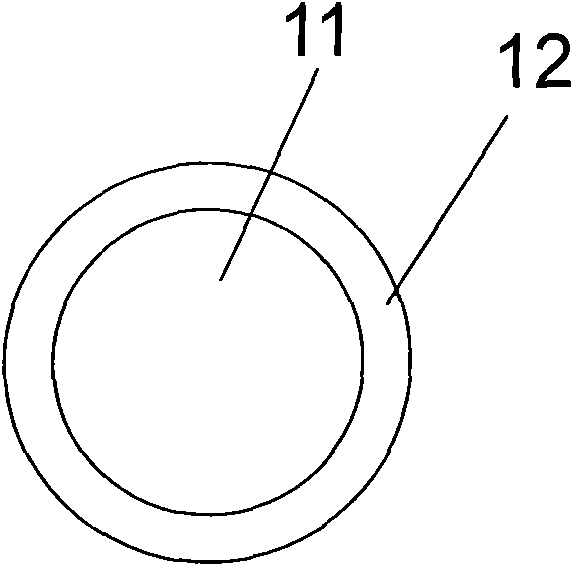

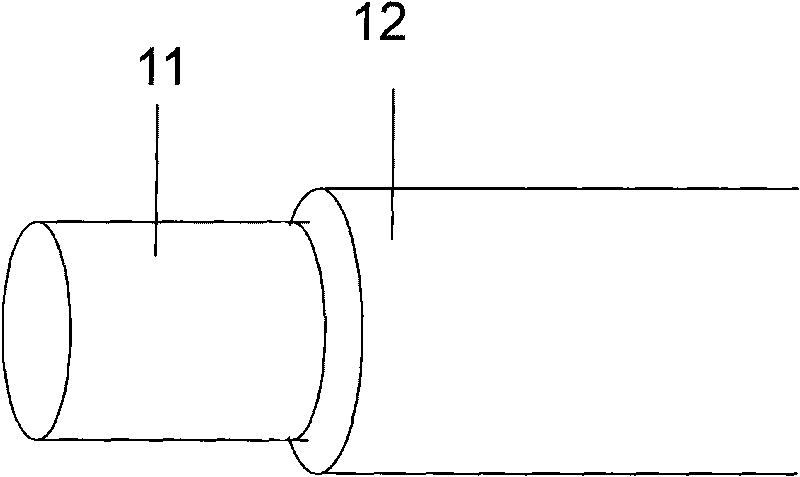

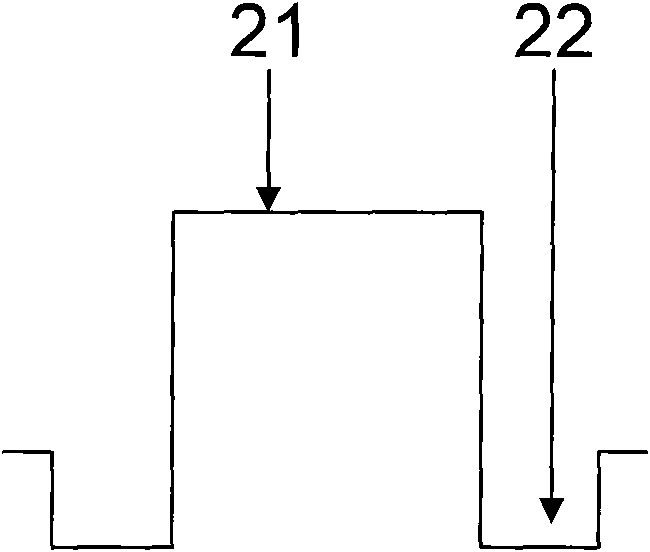

[0047] (1) The preform is made by PCVD process, and the monofilament is drawn. The preform is a two-layer coaxial structure, such as Figure 1a , Figure 1b As shown, the diameter of the core layer 11 is 17mm, and the diameter of the cladding layer 12, that is, the diameter of the preform is 20mm, then the core-to-clad diameter ratio is 0.85, and its refractive index profile is as follows Figure 2a As shown, its refractive index profile can also be used as Figure 2b The prefabricated rod shown; the preformed rod is drawn into monofilaments with the same diameter in the range of 1 to 2 mm on an ordinary optical fiber drawing tower;

[0048] (2), the monofilament obtained by drawing is cut into the same length, and each section of 900mm is several sections long. After cleaning and drying it, get 270 monofilaments and arrange them in a densely packed manner, such as image 3 shown;

[0049] (3), put the mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com