Vacuum exhaust system for die casting

A technology of vacuum exhaust and vacuum tank, applied in the field of vacuum system, can solve the problems of small exhaust rate of pipeline, low efficiency, long response time of cavity vacuum degree, etc., so as to reduce the vacuum degree response time and improve exhaust efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

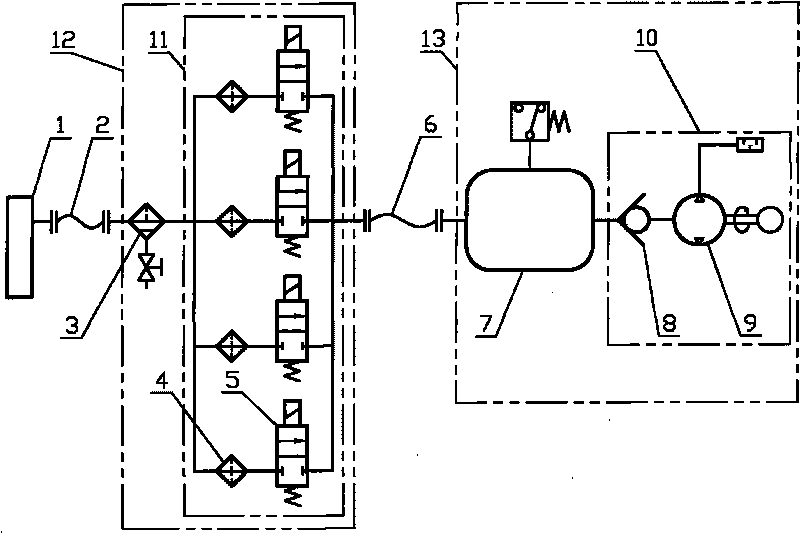

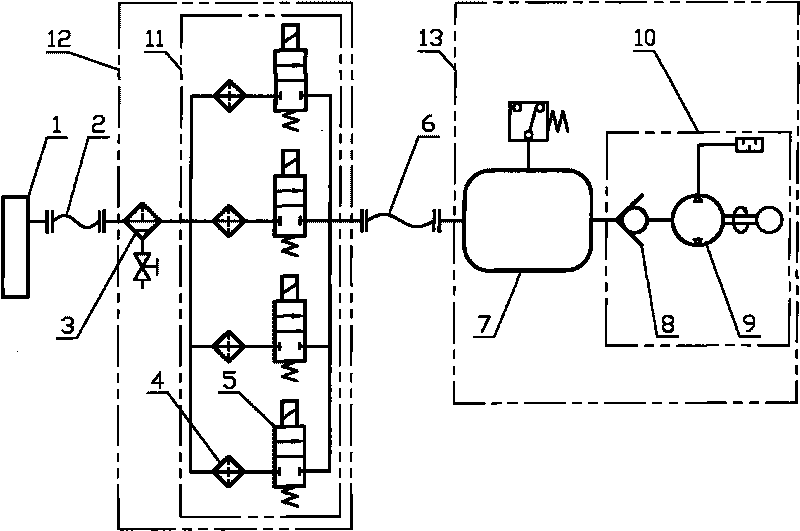

[0011] The specific structure, working principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] A vacuum exhaust system for die-casting provided by the present invention includes a module one 12 and a module two 13. The module one is composed of an impurity separator 3 and a parallel assembly 11, and each group of the parallel assembly consists of a solenoid valve 5 and a The electromagnetic valve is connected in series with a filter 4; the second module includes a vacuum machine 10, a vacuum tank and an accessory 7, and the vacuum machine 10 is assembled from a check valve 8, a vacuum pump and an accessory 9; impurities The separator 3 communicates with the outlet of the mold cavity 1 through the short hose 2, and the vacuum tank and the accessories 7 communicate with the parallel assembly 11 through the long hose 6, and at least two groups of parallel assemblies are connected in parallel.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com