Flexible jaw swing arm non-expansion drum device

A technology of expanding and shrinking reels and movable jaws, which is applied in the field of rolling mills, can solve problems such as the inability to clamp materials tightly in the jaws, inconvenient production activities, oil leakage at the jaws, etc., and achieve low installation requirements, flexible and convenient adjustment methods, Simple and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, but the present invention is not limited to the following examples;

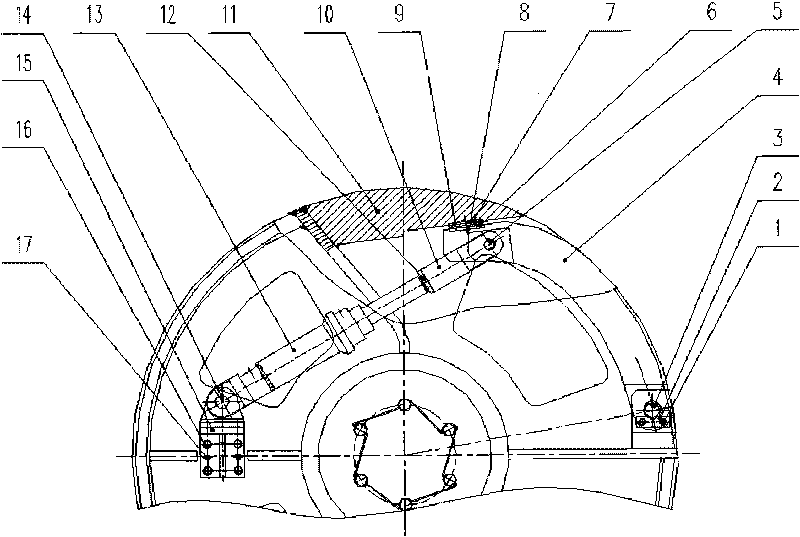

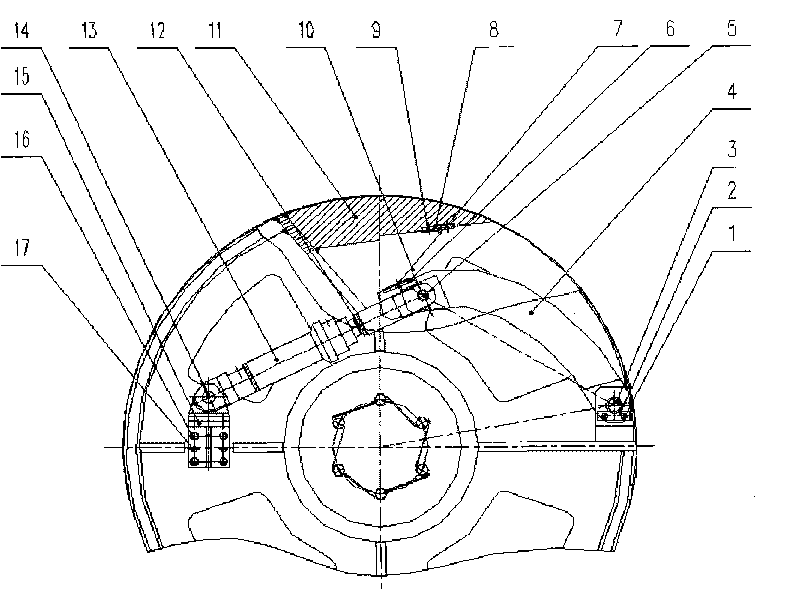

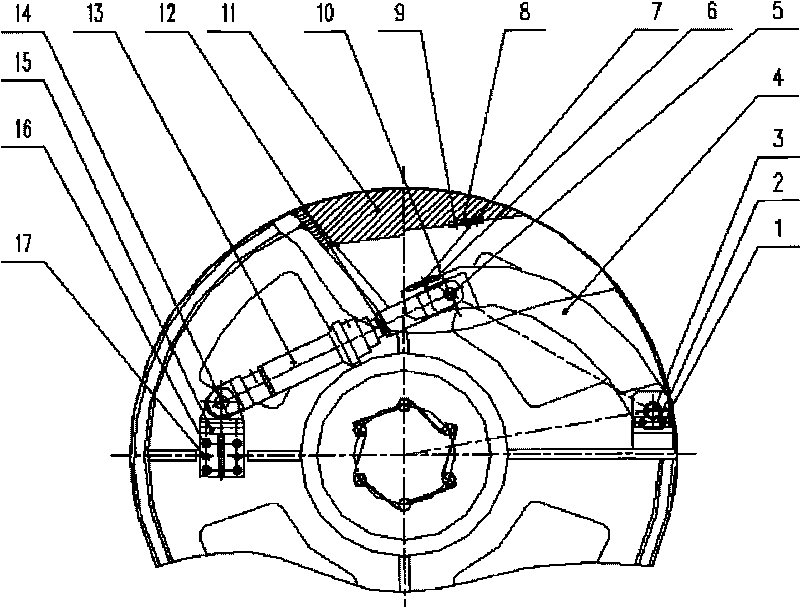

[0017] Such as figure 1 , figure 2 The shown movable jaw swing arm has no expansion and contraction reel device, including a jaw power device, a jaw positioning device, a jaw power device support, and a jaw positioning device support; the jaw power device is composed of a pin C14 passes through the lug plate hole of hydraulic cylinder 13 and is hinged on the jaw power unit support. The jaw power unit support is composed of bolt d16 and pin 17 to fix the support 15 on the reel 11 side; The jaw positioning device is set as a bow-shaped block 4, and the top of the upper end of the bow-shaped block 4 is provided with a movable jaw plate 6 fixed by a bolt b7; the fixed jaw plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com