High-efficiency and energy-saving filature collecting tank

A high-efficiency, energy-saving, collecting tank technology, applied in the direction of silk reeling, can solve the problems of time-consuming and laborious, incomplete collection, etc., and achieve the effect of complete collection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

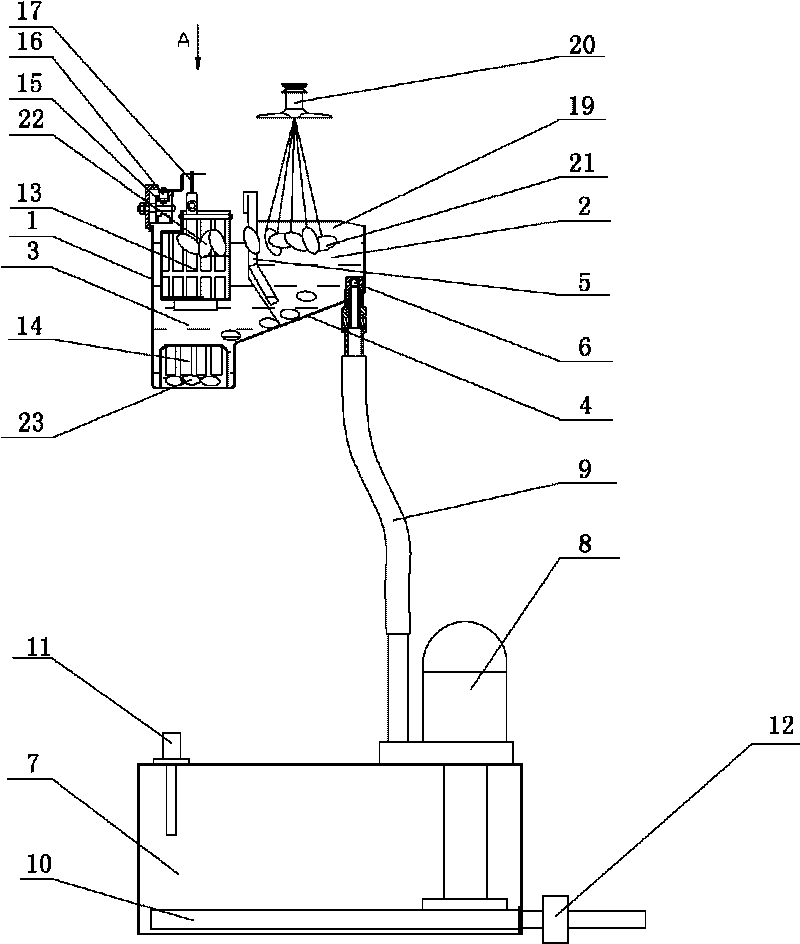

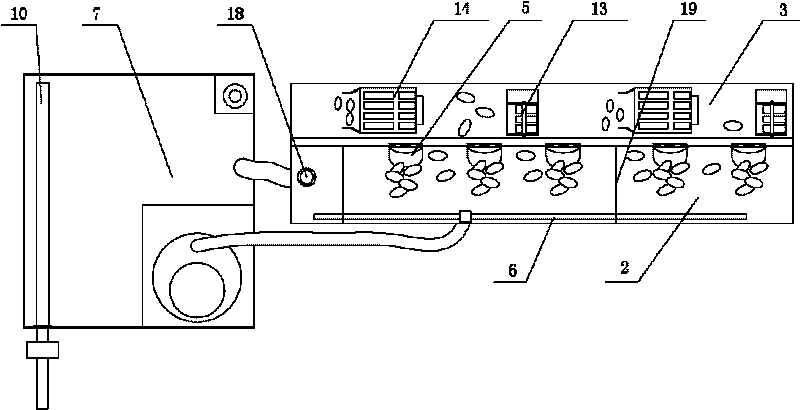

[0019] Embodiment: the high-efficiency energy-saving silk reeling collection tank of this example, as figure 1 , figure 2 , a frame 1 is arranged, and the frame is provided with a silk reeling tank 2 and a collection tank 3 arranged in parallel, the silk reeling tank and the collection tank are connected as a whole, and the bottom of the silk reeling tank 2 communicates with the collection tank through a swash plate 4. Between the silk reeling tank 2 and the collecting tank 3, a cocoon board 5 is provided, and the cocoon board is provided with one piece for each thread. The passage that thread cocoon 22 passes, and leave the gap that allows pupa liner 23 to pass through at the bottom of the cocoon plate and the silk reeling groove. The silk reeling tank 2 is internally connected with 40 small fences 19 to cut off the silk reeling groove, and 3 cocoon boards 5 are arranged between adjacent small fences. The collection tank 3 is provided with a floating cocoon catcher 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com