Welding fume purification device for electroslag pressure welding on construction site and using method thereof

A technology of electroslag pressure welding and construction site, applied in chemical instruments and methods, separation methods, auxiliary devices, etc. Use and other problems to achieve the effect of guaranteed effect, simple structure and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

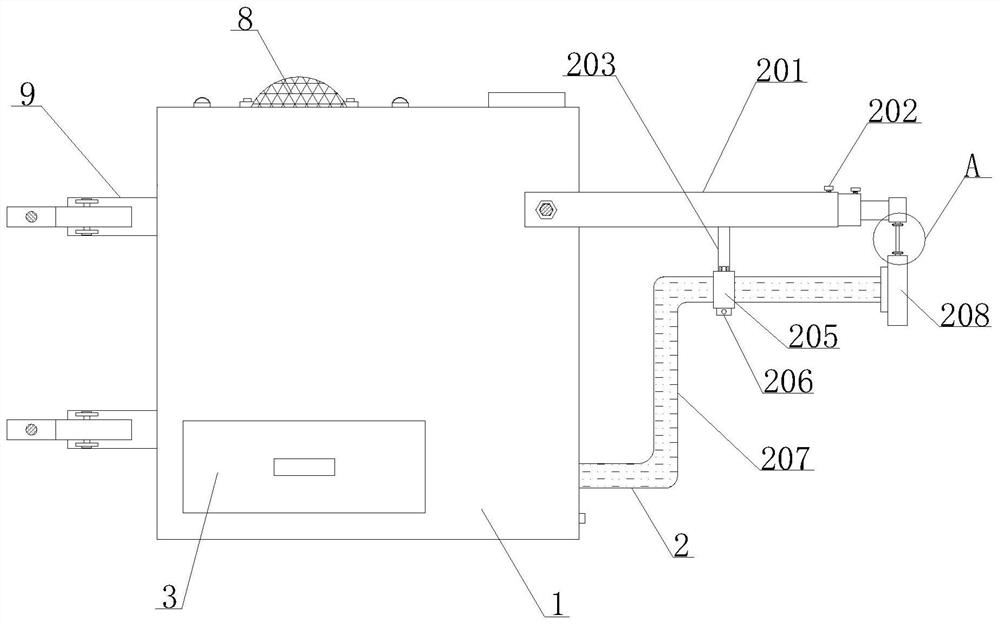

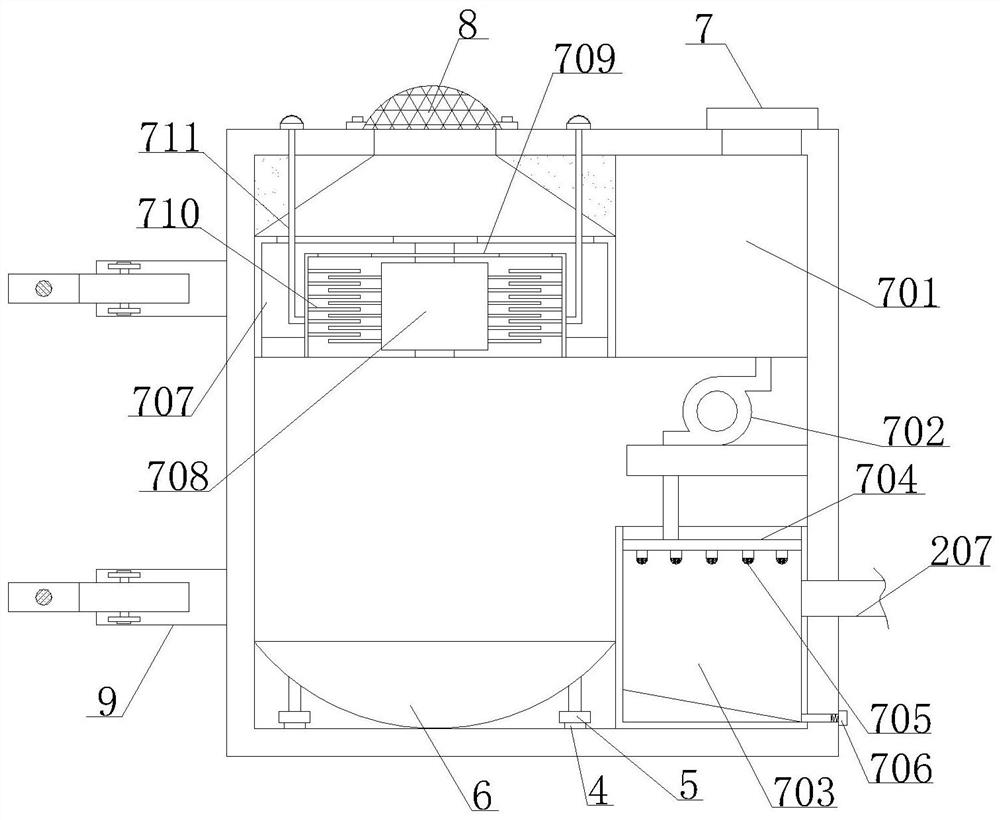

[0035] see Figure 1-7 , the present invention provides a technical solution: a welding fume purification device for electroslag pressure welding on a construction site, comprising a box body 1, a collection component 2 is installed on the outer surface of the right side of the box body 1, and a blocker is arranged on the front of the box body 1 Plate 3, a slide rail 4 is installed at the bottom of the inner wall of the box body 1, a slider 5 is slidably installed on the surface of the slide rail 4, a collection groove 6 is installed on the top of the slider 5, and a dust removal mechanism 7 is installed inside the box body 1. A dust cover 8 is installed on the top of the body 1 , and a clamping mechanism 9 is installed on the left outer surface of the box body 1 .

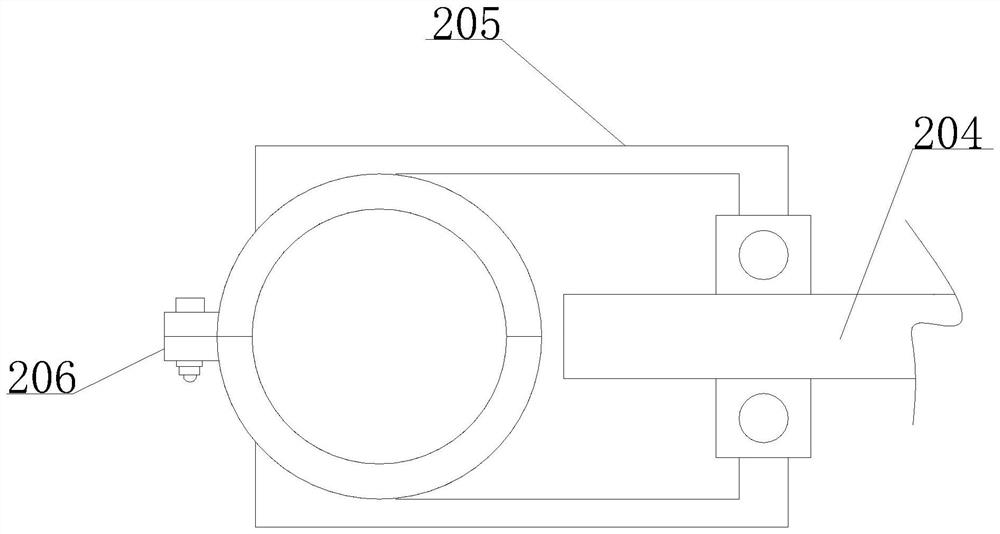

[0036] The collection assembly 2 includes a telescopic rod 201. The right outer surface of the box body 1 is hinged to the telescopic rod 201. The surface of the telescopic rod 201 is screwed with a fixing knob 20...

Embodiment 2

[0045] see Figure 1-7 , the present invention provides a technical solution: a welding fume purification device for electroslag pressure welding on a construction site, comprising a box body 1, a collection component 2 is installed on the outer surface of the right side of the box body 1, and a blocker is arranged on the front of the box body 1 Plate 3, a slide rail 4 is installed at the bottom of the inner wall of the box body 1, a slider 5 is slidably installed on the surface of the slide rail 4, a collection groove 6 is installed on the top of the slider 5, and a dust removal mechanism 7 is installed inside the box body 1. A dust cover 8 is installed on the top of the body 1 , and a clamping mechanism 9 is installed on the left outer surface of the box body 1 .

[0046] The collection assembly 2 includes a telescopic rod 201. The right outer surface of the box body 1 is hinged to the telescopic rod 201. The surface of the telescopic rod 201 is screwed with a fixing knob 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com