Ammonia fog collecting and treating system for electrolytic plant

An electrolysis workshop and treatment system technology, applied in the field of ammonia mist collection and treatment system, can solve the problems that the guide rail cannot be made of metal materials, the environment in the electrolysis area is difficult to meet the standard, and affects the health of workers, so as to solve the difficulty of waste gas collection and treatment, and daily operation Low cost, good for physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

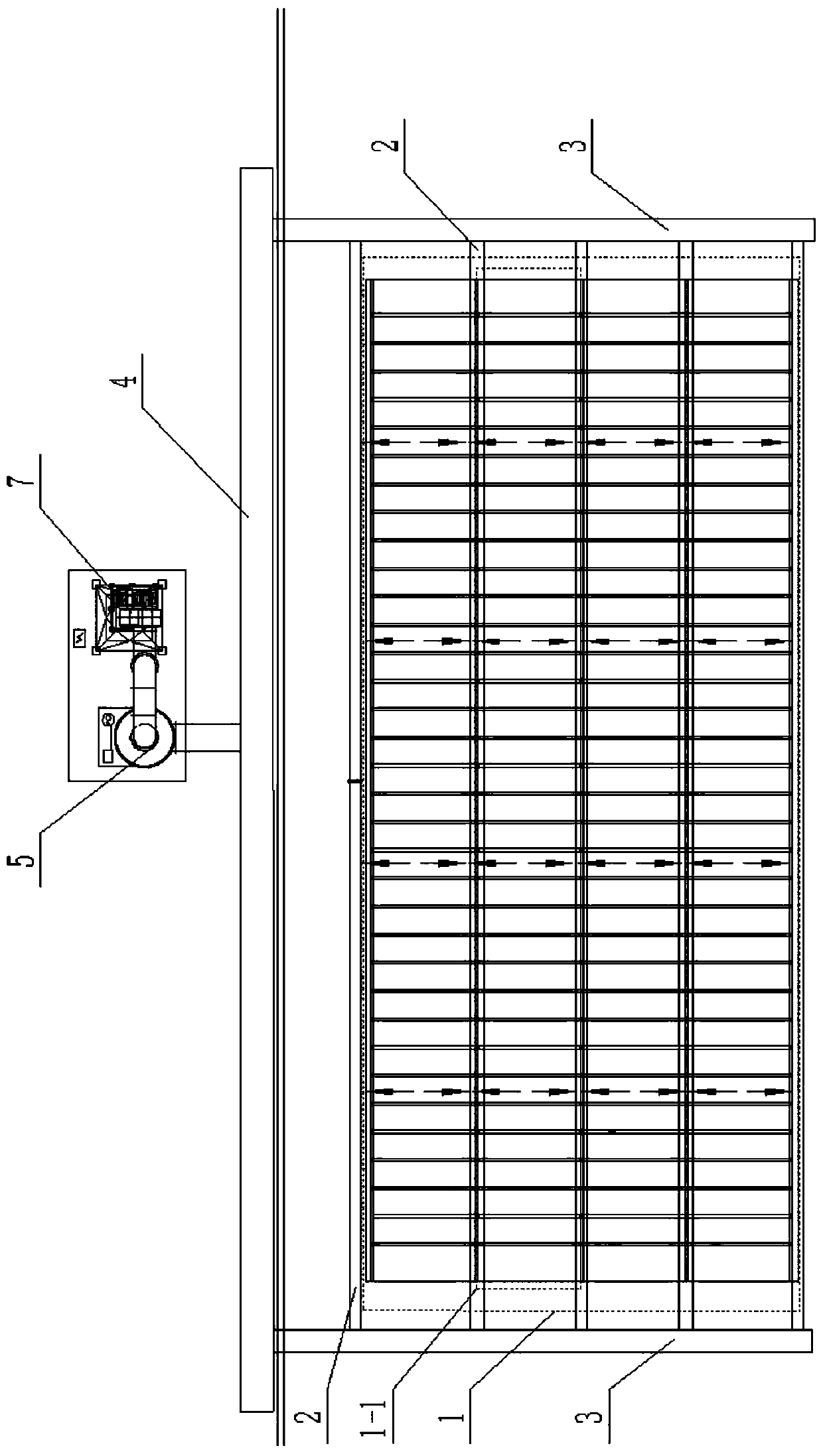

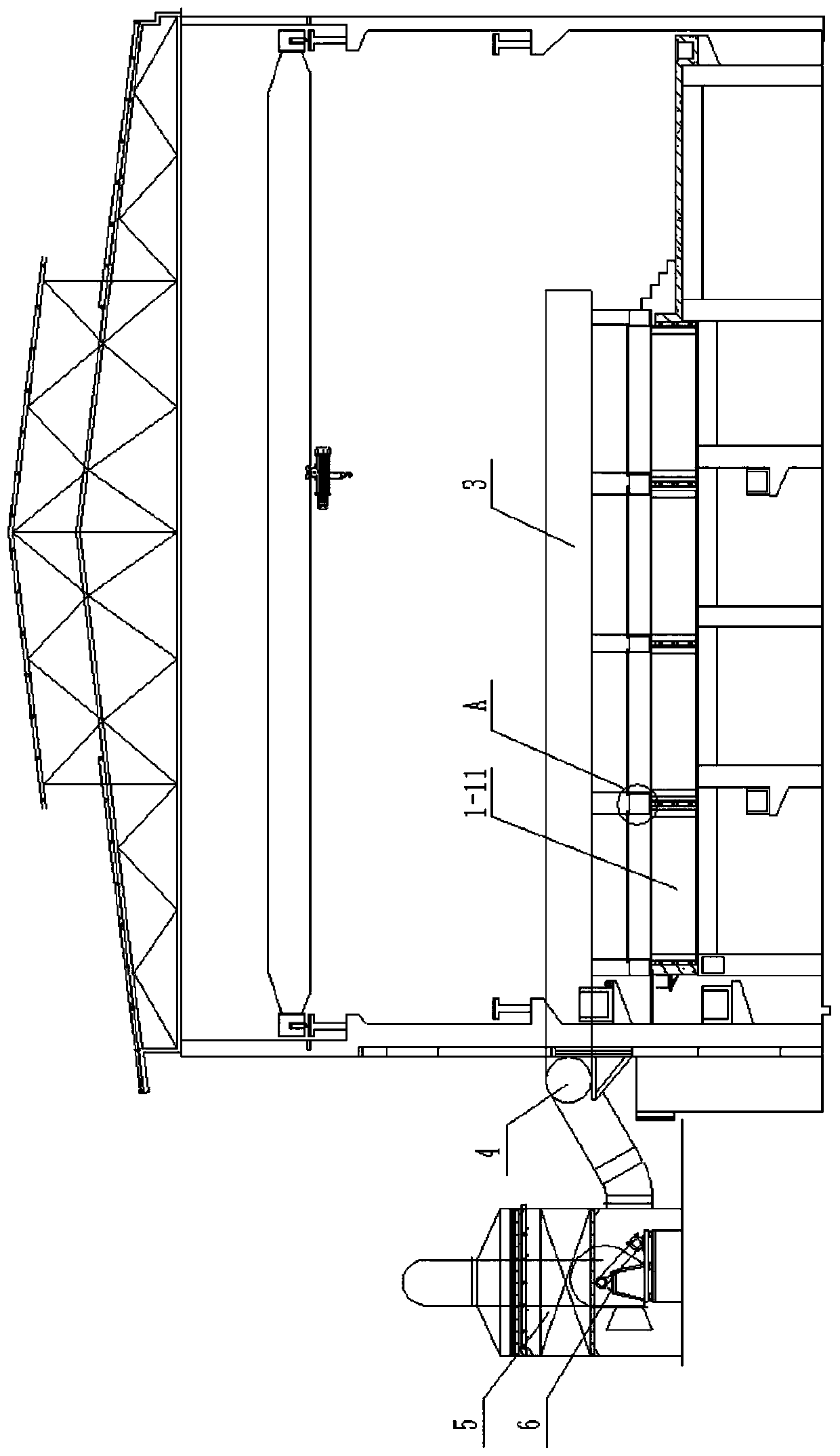

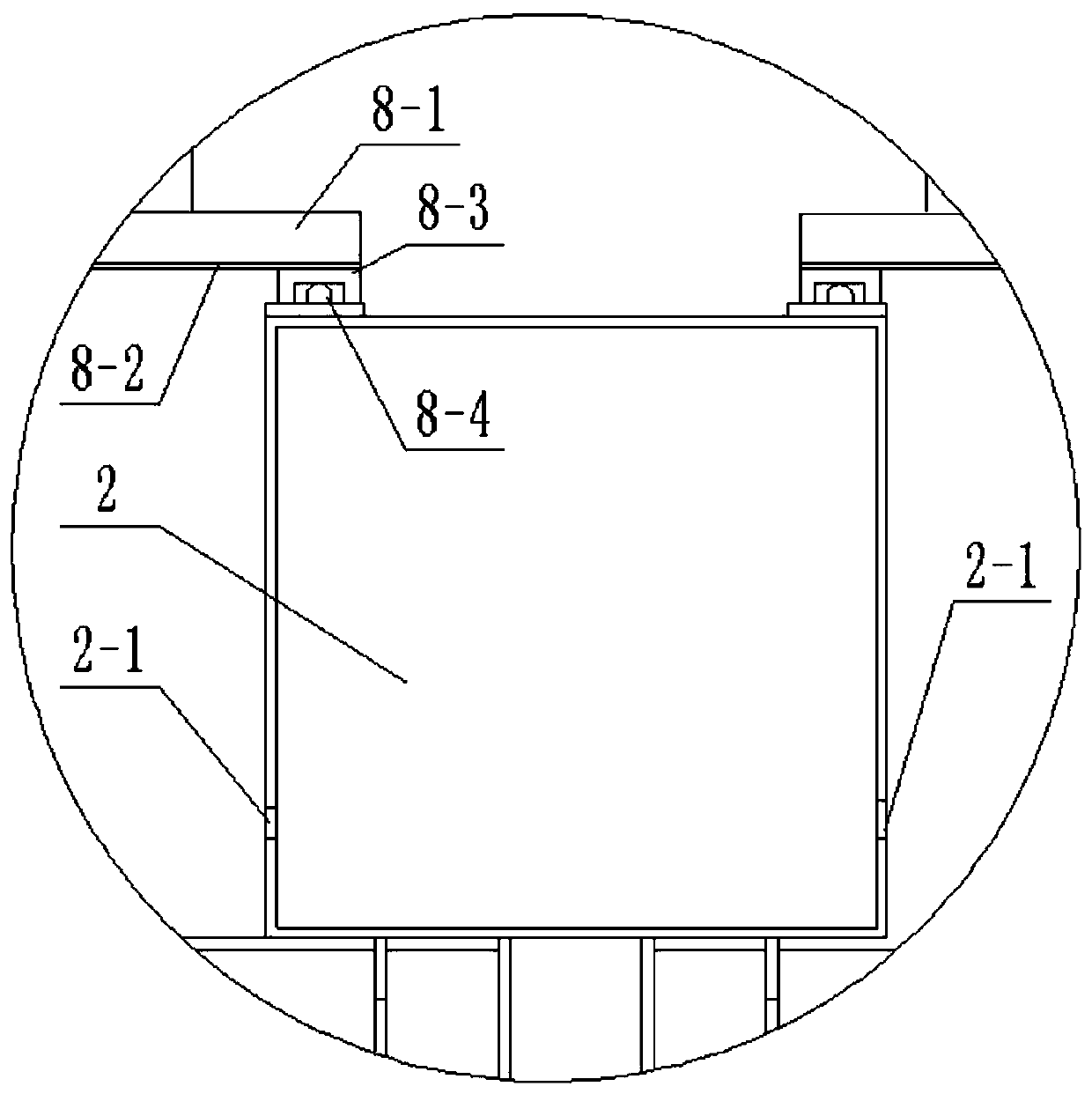

[0018] Such as Figure 1 to Figure 4 As shown, an ammonia mist collection and treatment system in an electrolysis workshop includes electrolysis area 1, inter-tank suction pipe 2, branch suction pipe 3, main suction pipe 4, ammonia gas absorption tower 5, fan 6, and chimney 7 , Laminating device.

[0019] The size of the electrolysis zone 1 is: 72m in length and 15.3m in width, including 4 electrolytic cell groups 1-1 arranged side by side, and the electrolytic cell group 1-1 is composed of 12 electrolytic cells 1-11 arranged side by side; The number of tubes 2 is 5. In the electrolysis area 1, there are inter-tank suction pipes above the outer side walls of the electrolytic cell group 1-1 located at both ends, and above the adjacent side walls of the adjacent electrolytic cell group 1-1. 2; The number of branch suction ducts 3 is 2, and they are respectively located on both sides of the electrolysis zone 1. Total suction duct 4 is communicated, and the air outlet of total s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com