Anticorrosive dust-collecting energy-saving chimney

A chimney and flue technology, applied in the field of chimneys, can solve the problems of not curing the surface but not the root cause, the inner sleeve is expensive, and achieving the effects of low cost, good environmental protection effect and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

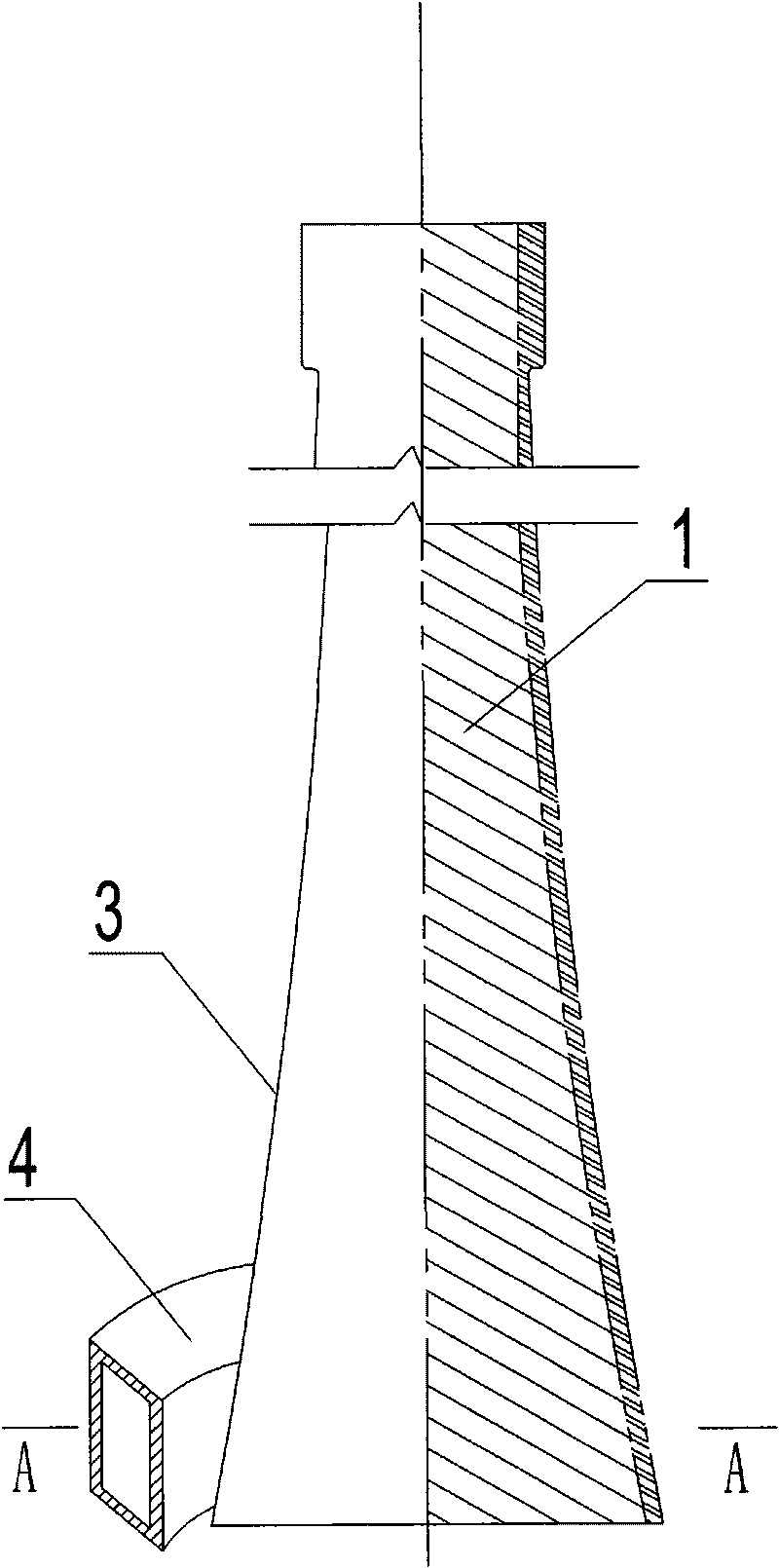

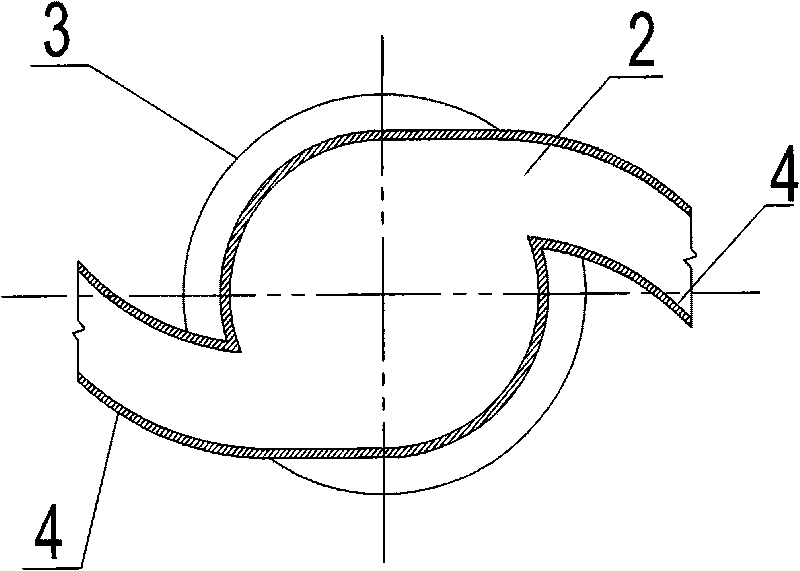

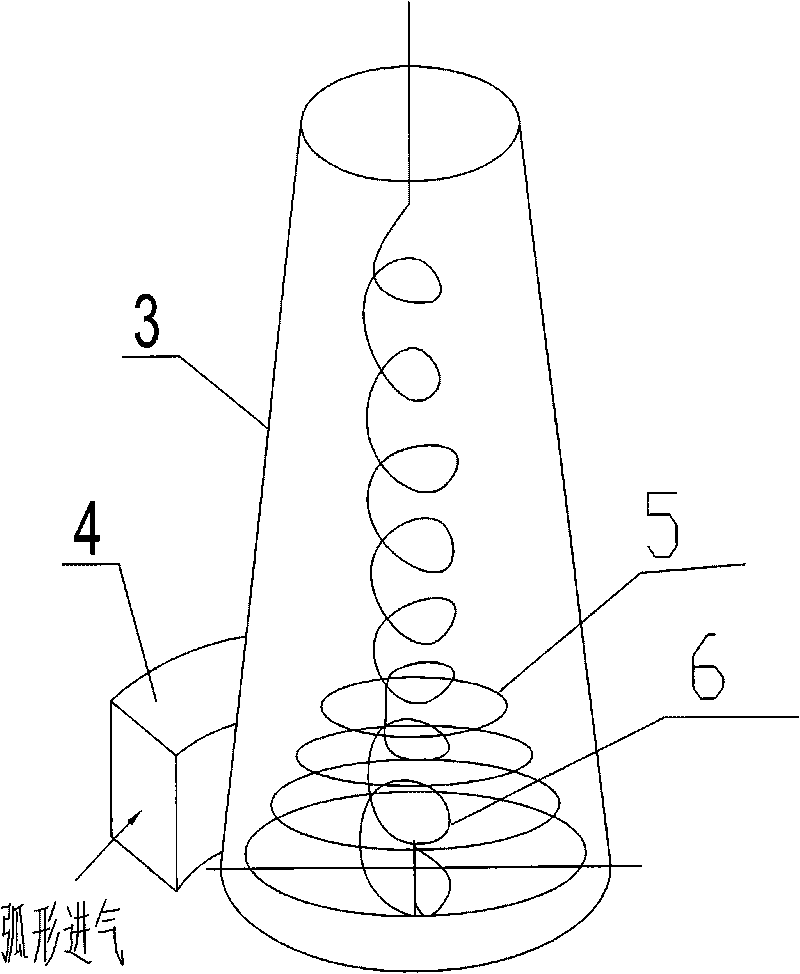

[0016] according to Figure 1 to Figure 3 And the anti-corrosion, dust-collecting and energy-saving chimney of the present invention with the above structure, its chimney cylinder 3, the inner wall of the chimney cylinder 3 is provided with an inner bore helix 1 with a helix angle of 60°; see figure 1 with figure 2 , the outlet 2 of the arc-shaped flue 4 outside the lower end of the chimney cylinder 3 communicates with the inner bore helix 1, and the arc rotation direction of the arc-shaped flue 4 is in the same direction as the helical direction of the inner bore helix 1 (The same is right-handed) and the arc-shaped flue 4 is smoothly connected with the inner bore helix 1.

[0017] The chimney barrel 3 is constructed of bricks with an inner chamber, and the bottom diameter of the chimney barrel 3 is ¢9 meters and 100 meters high. The chimney shell 3 has 5 different slope ratios from bottom to top, and they are as follows: the first slope ratio i 1 =0.06~0.08, second slope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com