A method for testing the sealing performance of insulating glass in service

A glass-sealed and hollow technology, which is applied in the direction of testing fluid tightness by detecting the dimensional change of the measured structural components, and using liquid/vacuum degree for liquid tightness measurement, etc., to ensure health status, safety and reliability, reliable use, The effect of simple non-destructive testing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

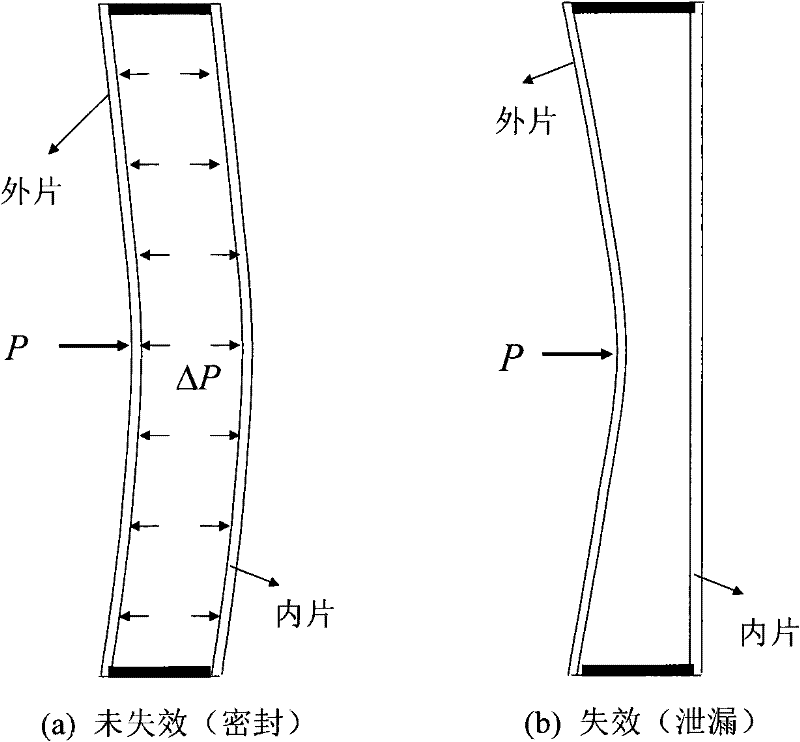

[0071] Example 1: Laboratory simulation of glass deflection changes in the state of sealing and leakage of the hollow layer of insulating glass

[0072] In this test, the hollow glass sample size is 6mm+12mm+6mm, and the length and width are 2000mm×1200mm. The specific implementation steps are as follows:

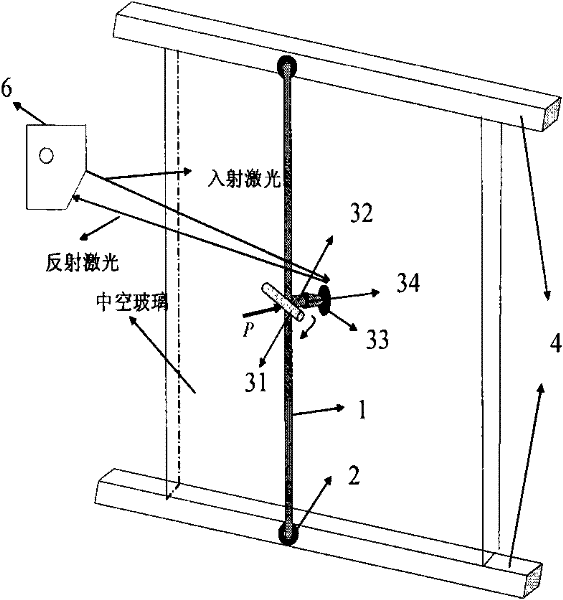

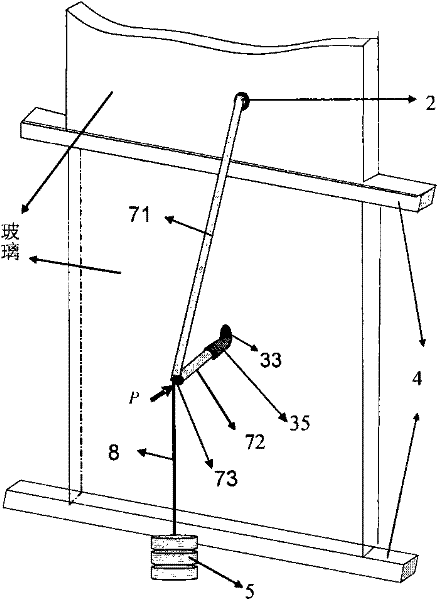

[0073] (1) Attach the two suction cups to the middle of the short edge of the insulating glass, and adjust the guide rod so that the force-applying screw is aligned with the center of the outer sheet of the insulating glass (the outer sheet in this embodiment is taken as an example). Rotate the screw force device so that the end of the force screw rod just touches the outer sheet of the insulating glass, and pad an elastic sheet at the contact part between the glass and the screw rod to prevent the glass from being damaged by rigid contact.

[0074] (2) Adjust the laser displacement sensor so that the laser measurement point is aligned with the center of the outer sheet of...

Embodiment 2

[0082] Example 2: On-site detection of the sealing performance of the hollow layer of insulating glass

[0083] Project introduction: The hollow glass curtain wall of a building was completed in May 2001, with a total of 6 floors, of which glass curtain walls are installed on the 2nd to 5th floors. The empty glass specification is 6mm+12mm+6mm, and the length and width are 2000mm×1200mm. During detection, each layer randomly selects two pieces of insulating glass for measurement, installs the measuring device according to the steps (1) and (2) of Example 1, and loads according to the step (3), the loading force is 25kg, and the deflection of the outer glass is shown in the table 2.

[0084] Table 2 On-site detection of central deflection of insulating glass outer sheet

[0085] Numbering A2 B2 A3 B3 A4 B4 A5 B5 A6 B6 Deflection (mm) 1.011 1.085 1.154 1.142 1.035 1.098 1.147 1.167 1.210 1.138

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com