Miniature back scattering X-ray inspection device

An inspection device and backscattering technology, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as weak transmission ability, low scanning speed and image resolution, small maximum detection distance, etc., to achieve The effect of widening the data area, easy radiation protection, and real-time recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

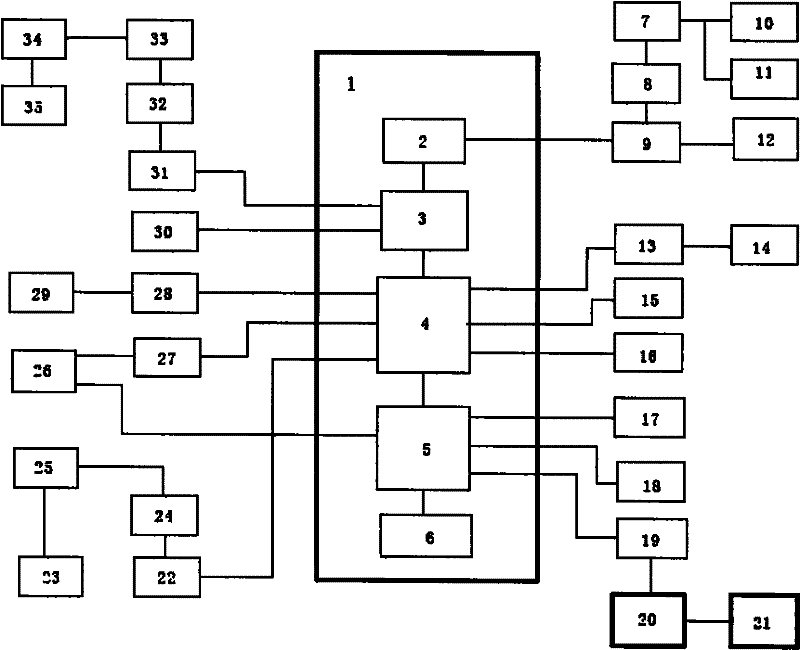

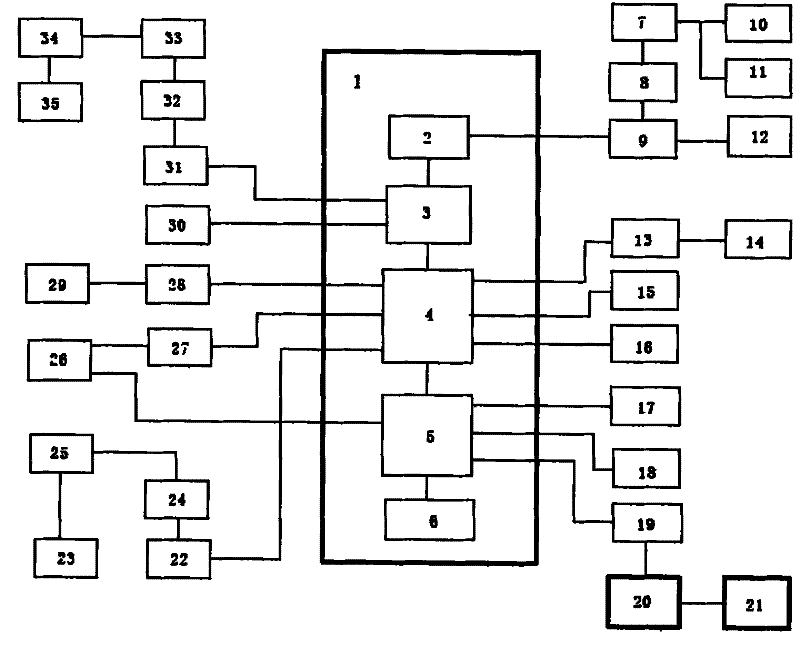

[0029] The present invention comprises: a central control and processing unit (CCPU) 1, a chopper wheel controller 28 connected to the central control and processing unit 1, an X-ray source controller 22, a host computer 9, a ray screen door controller 27, and a system Control keyboard 16 , scan speed display 13 , backscatter signal preamplifier 31 , radiation warning device 17 , safety interlock switch 19 and temperature control module 15 . The central control and processing unit 1 includes a network module 2 , a digital signal processing circuit 3 , a system control circuit 4 , a safety interlock logic circuit 5 , and a low-voltage power supply module 6 . The chopping wheel system 29 that is connected with the chopping wheel controller 28, the column that is arranged on the chopping wheel system 29, the wheel synchronous sensor 30, the backscattering signal adapter 32 that is connected with the backscattering signal preamplifier 31, the backscattering signal Scatter detector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com