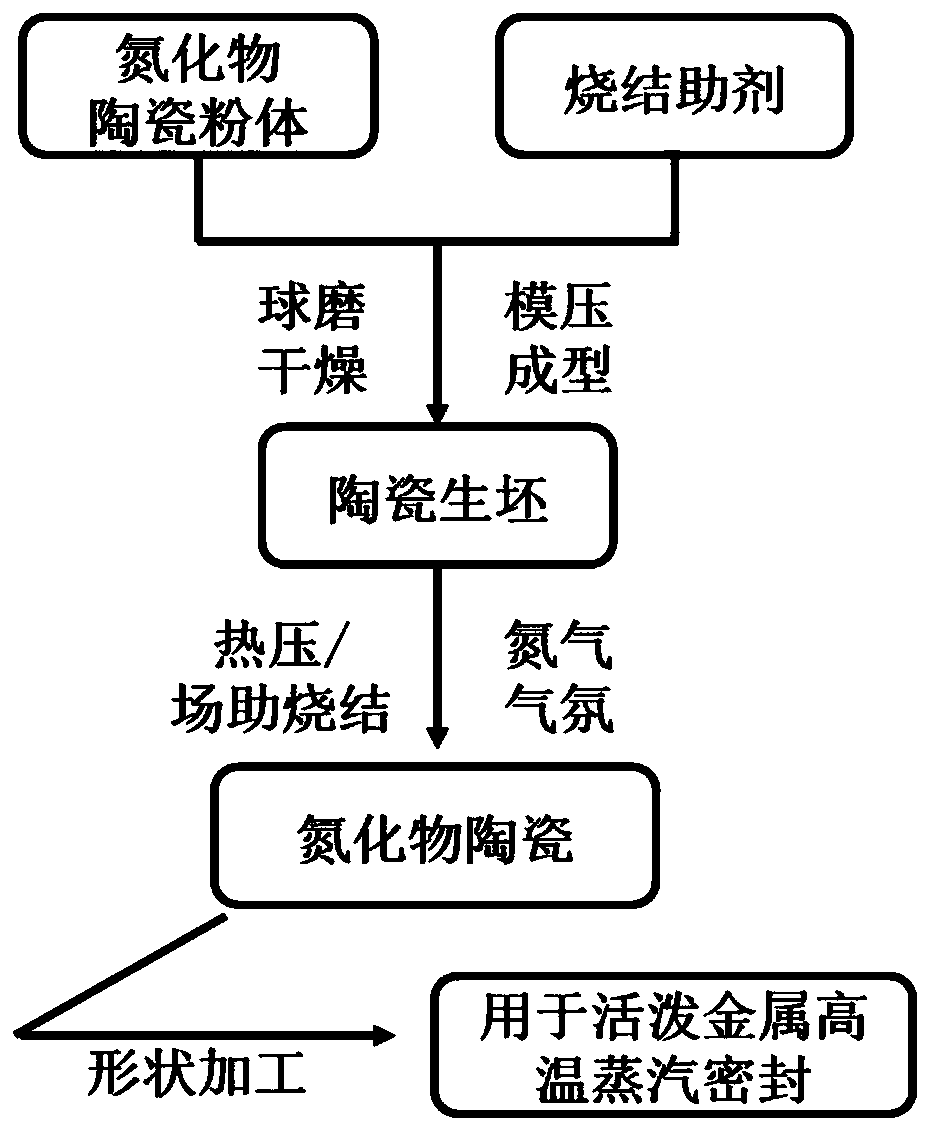

Ceramic material for active metal high-temperature steam sealing and protection and preparation method thereof

A technology of ceramic material and active metal, which is applied in the field of ceramic material and preparation of active metal high-temperature vapor, and achieves the effects of low cost, promotion of industrialization, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

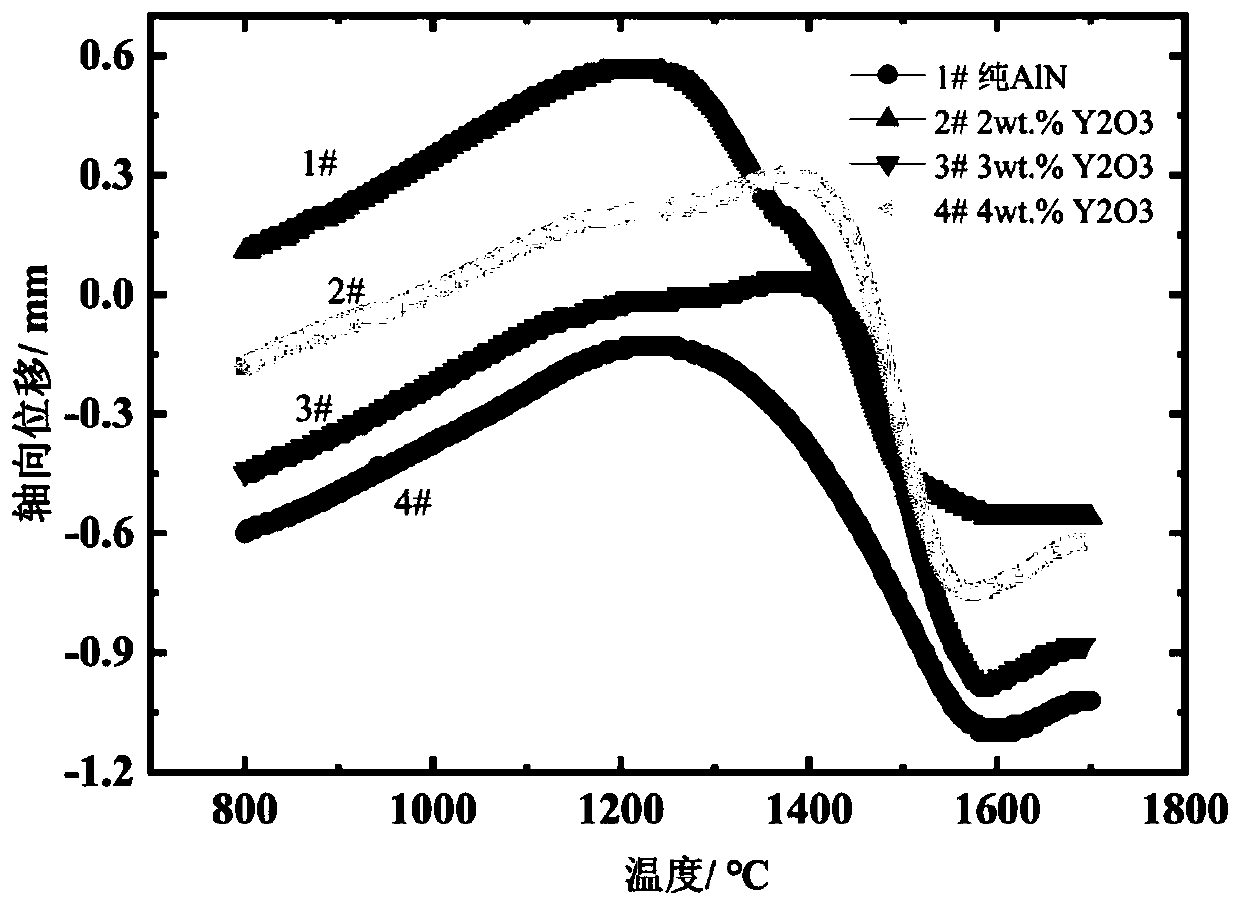

[0034] According to AlN powder, sintering aid Y 2 o 3The mass percentage of the powder is 97:3, and an appropriate amount of raw materials is weighed, and the used AlN, Y 2 o 3 The average particle size of the powder is 2 μm, and the powder is milled for 3 hours by a ball mill, and then dried in an oven at 80° C. for 12 hours. The ball mill adopts Retsch PM100, the same below.

[0035] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO 2 The mass ratio of balls = 1:1:4 is used for ball milling, and the program of the ball mill is set to stop for 2 minutes every 10 minutes of operation.

[0036] Weigh 8g of mixed powder and spread it into a graphite mold with an inner diameter of 25mm, such as figure 1 Shown; the samples were pre-compressed at 6 MPa for 30 s before field-assisted sintering.

[0037] Field-assisted sintering is selected under nitrogen atmosphere. The specific sintering...

Embodiment 2

[0039] According to AlN powder, sintering aid MgO, Y 2 o 3 The proportion by mass percentage is 94:3:3, and the appropriate amount of raw materials is weighed, and the used AlN, MgO, Y 2 o 3 The average particle size of the powder is 2 μm, and the powder is milled for 3 hours by a ball mill, and then dried in an oven at 80° C. for 12 hours.

[0040] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO 2 The mass ratio of balls = 1:1:4 is used for ball milling, and the program of the ball mill is set to stop for 2 minutes every 10 minutes of operation.

[0041] Weigh 8g of the mixed powder and spread it into a graphite mold with an inner diameter of 25mm. The sample is pre-pressed at 6MPa for 30s and then hot-pressed and sintered.

[0042] Hot-pressing sintering under nitrogen atmosphere is selected, and the specific sintering process is: sintering temperature 1550°C, heating rate 10°C / mi...

Embodiment 3

[0044] According to AlN powder, BN powder, sintering aid Y 2 o 3 The ratio of mass percentage is 82.4:14.6:3 Weigh appropriate amount of raw materials, used AlN, BN, Y 2 o 3 The average particle size of the powder is 2 μm, and the powder is milled for 3 hours by a ball mill, and then dried in an oven at 80° C. for 12 hours.

[0045] The ball milling process is as follows: put the raw material powder into a 125ml nylon ball milling tank, according to powder: alcohol: ZrO 2 The mass ratio of balls = 1:1:4 is used for ball milling, and the program of the ball mill is set to stop for 2 minutes every 10 minutes of operation.

[0046] Weigh 8g of the mixed powder and spread it into a graphite mold with an inner diameter of 25mm. The sample is pre-pressed at 6MPa for 30s and then hot-pressed and sintered.

[0047] Hot-pressing sintering under nitrogen atmosphere is selected. The specific sintering process is as follows: sintering temperature 1600°C, heating rate 10°C / min, holding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com