Preparation method of enhanced light stabilizer for straw bundling net

A light stabilizer and enhanced technology, which is applied in the field of preparation of enhanced light stabilizers for straw bale nets, can solve the problems of lack of antioxidant additives, reduced service life, easy to be oxidized and decomposed, etc., and achieve thermodynamic stability. Good, improve the light aging resistance, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

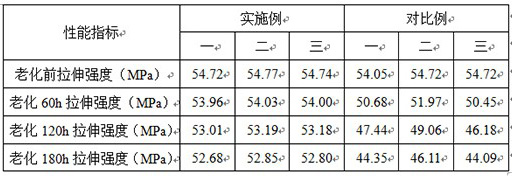

Examples

Embodiment 1

[0023] S1. Add nano-zinc oxide into the hydrochloric acid solution with a temperature of 57°C and a concentration of 0.8mol / L, stir and mix evenly, disperse ultrasonically for 10 minutes, then let it stand for heat preservation for 5 hours, wash and dry to obtain acid-treated zinc oxide, According to the mass ratio of 18:1:3, the acid-treated zinc oxide, cerium carbonate, and zirconium dioxide are jointly added to the ball mill, and the ball mill is fully mixed to obtain a mixed powder;

[0024] S2. Add the mixed powder in step S1 into a 17% aqueous solution of polyvinyl alcohol, stir and disperse, and add diethylenetriaminepentaacetic acid and vinyltris(2-methoxyethoxy)silane, Stir and mix for 20 minutes, and dry at a temperature of 95°C until constant weight to obtain a modified product. The mass ratio of silane is 22:48:4:1;

[0025] S3. Add p-tert-octylphenol to absolute ethanol at a temperature of 3° C., heat and stir to dissolve, add carbon disulfide and 4-n-butylamino-...

Embodiment 2

[0028] A kind of preparation method of enhanced light stabilizer for bale net that the present invention proposes, comprises the following steps:

[0029] S1. Add nano-zinc oxide into the hydrochloric acid solution with a temperature of 60°C and a concentration of 1.4mol / L. After stirring and mixing evenly, ultrasonically disperse for 15 minutes, then stand for heat preservation for 6.5 hours, wash and dry to obtain acid-treated zinc oxide. , by mass ratio 19:1:4, acid-treated zinc oxide, cerium carbonate, and zirconium dioxide are jointly added in a ball mill, and fully ball milled and mixed to obtain a mixed powder;

[0030] S2. Add the mixed powder in step S1 into a 21% aqueous solution of polyvinyl alcohol, stir and disperse, and add diethylenetriaminepentaacetic acid and vinyltris(2-methoxyethoxy)silane, Stir and mix for 30 minutes, and dry at 98°C until constant weight to obtain a modified product. The mass ratio of silane is 24:56:5.5:1;

[0031] S3. Add p-tert-octylp...

Embodiment 3

[0034] A kind of preparation method of enhanced light stabilizer for bale net that the present invention proposes, comprises the following steps:

[0035] S1. Add nano-zinc oxide into the hydrochloric acid solution with a temperature of 64°C and a concentration of 2mol / L. After stirring and mixing evenly, ultrasonically disperse for 20 minutes, then stand for heat preservation for 8 hours, wash and dry to obtain acid-treated zinc oxide, press The mass ratio is 20:1:5, the acid-treated zinc oxide, cerium carbonate, and zirconium dioxide are added to the ball mill, and the ball mill is fully mixed to obtain a mixed powder;

[0036]S2. Add the mixed powder in step S1 into a 25% polyvinyl alcohol aqueous solution, stir and disperse, and add diethylenetriaminepentaacetic acid and vinyltris(2-methoxyethoxy)silane, Stir and mix for 40 minutes, and dry at 102°C until constant weight to obtain a modified product, in which, mixed powder, polyvinyl alcohol aqueous solution, diethylenetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com