Patents

Literature

318 results about "Biethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multimodal polyethylene composition, mixed catalyst and process for preparing the composition

ActiveUS20090306299A1Distribution be very broadImprove processabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSingle sitePolymer

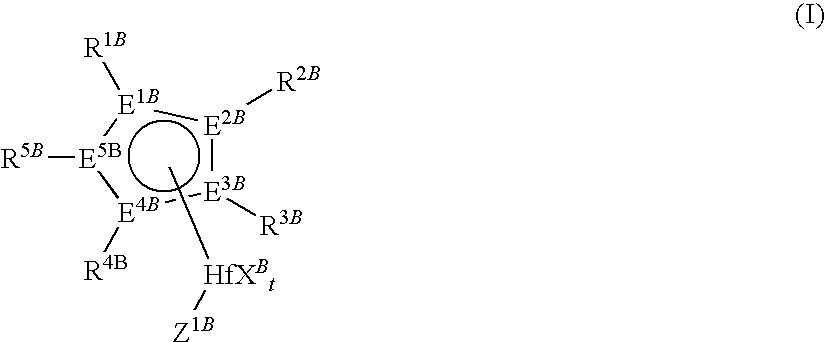

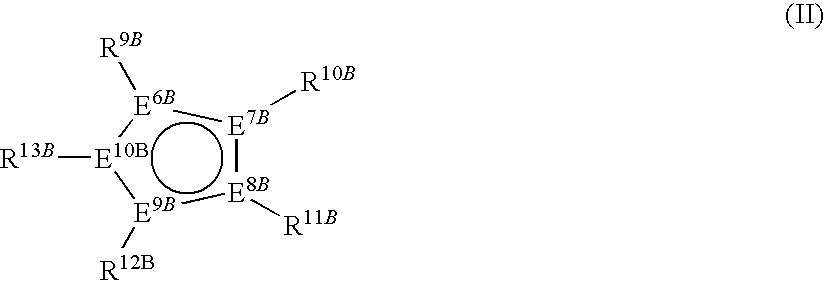

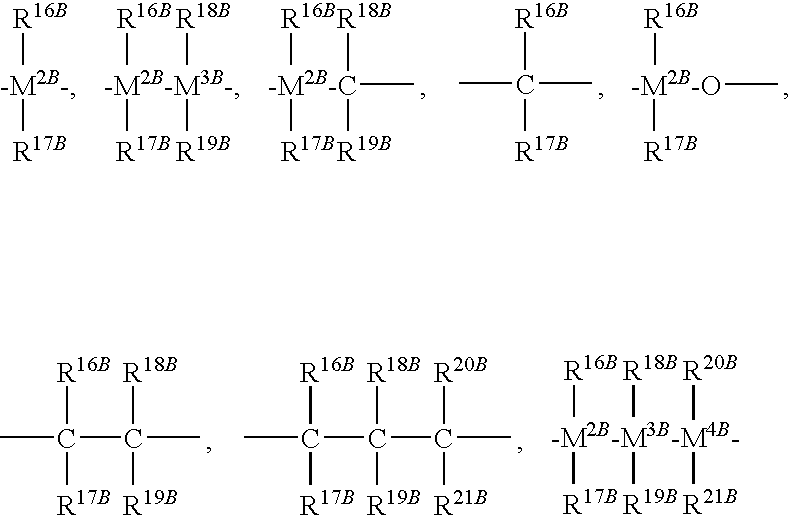

A multimodal polyethylene composition, in particular suitable for the preparation of films, but also textile articles, blow molded articles and injection molded articles is described. The polyethylene composition of the invention comprises at least three ethylene polymer fractions having distinct molecular weights or comonomer contents, said at least three ethylene polymer fractions comprising at least one first ethylene polymer fraction having a first molecular weight, a first comonomer content lower than a predetermined value and a first density; at least one second ethylene polymer fraction having a second molecular weight higher than said first molecular weight, a second comonomer content higher than said first comonomer content, and a second density; and at least one third ethylene polymer fraction having a third molecular weight higher than said first molecular weight, a third comonomer content lower than a predetermined value, and a third density; wherein said at least one first ethylene polymer fraction and said at least third ethylene polymer fraction are prepared by the use of a first and, respectively, third catalyst and said at least one second ethylene polymer fraction is prepared by the use of a second catalyst of the single site type. The films prepared from the composition of the invention have improved water vapor barrier properties. Furthermore, a mixed catalyst system comprising at least three catalyst components and a process particularly suitable to prepare the composition of the invention are described.

Owner:SNS CONFERENCE +1

Organosilicon sealant for LED (light-emitting diode) packaging

The invention relates to an organosilicon sealant for LED (light-emitting diode) packaging, belonging to the technical field of organosilicon sealants. The organosilicon sealant comprises a component A and a component B. The component A comprises 15-25 parts of divinyl polydimethylsiloxane silicon resin and 2-6 parts of platinum catalyst. The component B comprises 50-58 parts of divinyl polydimethylsiloxane silicon resin, 50-88 parts of methylhydropolysiloxane, 2-8 parts of reaction inhibitor, 30-40 parts of fumed silica, 2-10 parts of additive KH-560 and 20-25 parts of TiO2. The vinyl silicon resin, hydrogen-containing silicon oil and tetramethyltetravinylcyclosiloxane are subjected to addition reaction under the condition of the platinum catalyst to prepare the organosilicon electronic packaging adhesive with favorable comprehensive properties. The sealant is very suitable for LED packaging.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Flame-retardant, high-heat-conductivity, high-temperature-resistant and low-temperature-resistant addition organic silicon rubber and preparation method thereof

InactiveCN102627860AImprove thermal stabilityImprove thermal conductivityPtru catalystMethyl palmoxirate

The invention discloses organic silicon rubber, which has flame retardance, high heat conductivity, high temperature resistance and low temperature resistance and can be used for replacing the conventional organic silicon rubber. The organic silicon rubber comprises alpha,omega-divinyl polydimethylsiloxane, methyl hydrogen-containing polysiloxane, cerium oxide, zinc oxide, ferric oxide, alumina, hydroxyl ferric oxide, white carbon black, a catalyst and an aid in the weight ratio of (10-18):(1-6):(1-1.25):(5-25):(1-3):(10-12.5):(1-2.5):(10-25):(1-2.5):(0.003-1.25):(0.003-1.25).

Owner:邵成芬

Electrophoresis particle of polymer dye (pigment) for electronic ink and preparation method thereof

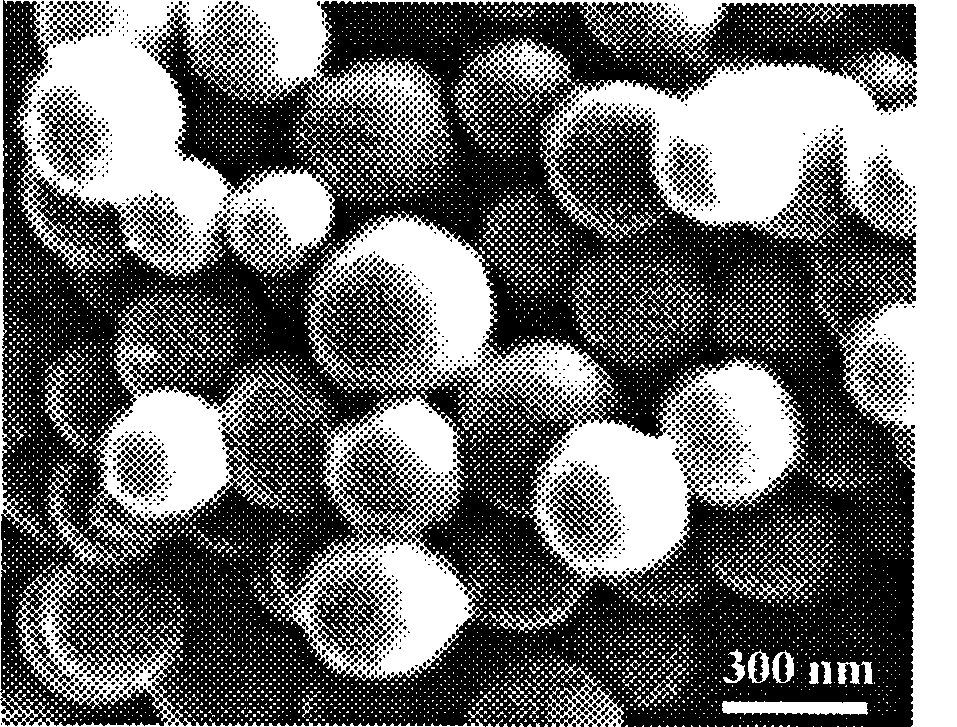

InactiveCN101544850AUniform particle sizeGood sphericityInksOrganic dyesCross-linkMethylene Dichloride

The invention relates to an electrophoresis particle of polymer dye (pigment) for electronic ink and a preparation method thereof, and belongs to technology of electrophoresis particle preparation. The electrophoresis particle uses dye as an initial raw material, and is prepared according to the following proportion that: the mass ratio of the dye to acryloyl chloride is 1:1-10; the mass ratio of the dye to styrene is 1:1-20; the mass ratio of the dye to divinylbenzene is 1:0.5-10; and the mass ratio of the dye to an initiator AIBN is 1:0.01-0.05. The preparation method comprises the following steps: carrying out functionalized modification on dye acidylation by acryloyl chloride in methylene dichloride to lead the dye to carry a polymerizable functional group; then, leading the dye to perform a polymerization reaction with styrene in ethanol for 4 to 12 hours by taking AIBN as the initiator and the divinylbenzene as a cross-linking agent to prepare the particle with particle diameter of between 200 and 300nm. The electrophoresis particle and the preparation method have the advantages of simple process, accessible raw materials, even particle diameter of the prepared colorful electrophoresis particle and good degree of sphericity. The electrophoresis particle of the organic polymer dye (pigment) not only maintains the advantages of bright color and proper density of the organic dye, but also overcomes the defects uneven shape of the organic dye particle, poor movement effect in disperse liquid under the action of an electric field.

Owner:TIANJIN UNIV

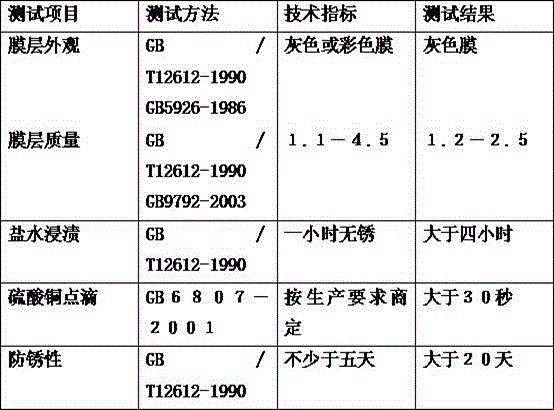

Metal surface conditioning agent and metal surface treatment technology

ActiveCN104131277ANo pollutionEasy to operateMetallic material coating processesEthylenediaminePhytic acid

The invention relates to a metal surface conditioning agent, which is composed of novel organic acidity, zinc nitrate, sodium molybdate, nicdel nitrate, sodium hydrogenfluoride, phytic acid, a nonionic surfactant and water; the novel organic acidity is the organic acidity obtained by respectively reacting ethene diamine or diethylenetriamine or triethylene tetramine or tetraethylenepentamine with citric acid. A metal surface treatment technology comprises the following steps: preparing the novel organic acidity, and using the novel organic acidity for complex formulation with zinc nitrate, sodium molybdate, nicdel nitrate, sodium hydrogenfluoride, phytic acid, the nonionic surfactant and water to obtain the metal surface conditioning agent. The concrete processing flow comprises the following steps: removing oil, washing, washing, pickling, neutralizing, conditioning surface, treating surface, performing post-treatment on surface or washing, performing air drying. The surface treatment technology can replace the current phosphatization technology, and has the technology advantages of environmental protection and simple operation, and is better than the phosphatization technology from the aspect of technology index.

Owner:DALIAN JIESHI CLEANING PRODS

Self-sharpening diamond abrasive material and preparation method thereof

ActiveCN103709993AReduce carbonizationMultiple ground anglesOther chemical processesDiethylenetriamineManganese

The invention discloses a self-sharpening diamond abrasive material. The self-sharpening diamond abrasive material comprises the following raw materials by weight: 75-85% of a diamond abrasive materail, 13-20% of metal powder and 2-5% of a binding agent. The particle size of the diamond abrasive material is 0.5 [mu]m-100 [mu]m; the metal powder comprises iron, cobalt, manganese, or a mixture thereof, or an alloy; and the binding agent comprises diethylenetriamine, 1,3-cyclohexanebis(methylamine), trimethylhexamethylenediamine, or a mixture thereof or one of the above. The self-sharpening diamond abrasive material is rough in surface and has more grinding surface angles. When particles are suffering from stress, frangibility causes the particles broken, so that novel sharp cutting edge is generated and the self-sharpening property is better. The self-sharpening diamond abrasive material is particularly suitable for ultrafine grinding and polishing of magnetic heads, hard disks, optical glasses and sapphire wafers.

Owner:河南鑫泓研磨材料有限公司

Building energy-saving and heat insulating nano ATO paint for inside and outside wall surface

InactiveCN101423727AGood heat insulationSave energyPolyurea/polyurethane coatingsMonoglycerideThermal insulation

The invention discloses a transparent nano-ATO thermal insulation coating for an exterior wall, which comprises the compositions in percentage by weight: 62.51 to 85.47 percent of polyurethane with the weight percent solid content of between 30 and 45 percent, 10.57 to 30.06 percent of ATO wet material with the weight percent solid content of between 10 and 30 percent, 3.41 to 5.46 percent of thickening agent WT-106, and 0.15 to 1.80 percent of conventional flatting agent. The invention also discloses a phase change heat storage microcapsule coating for an interior wall, which consists of 0.5 to 5 portions of phase change heat storage microcapsules and 3 to 20 portions of conventional adhesive, wherein the phase change heat storage microcapsules comprise the following compositions in percentage by weight: 400 to 800 portions of tridecyl alcohol, 0.5 to 15 portions of azodiisobutyronitrile, 1.2 to 15 portions of sorbitan monoglyceride, 80 to 230 portions of phenyl ethylene, and 50 to 150 portions of divinyl. The transparent nano-ATO thermal insulation coating can effectively solve the problem of thermal insulation of buildings.

Owner:曾庆琳

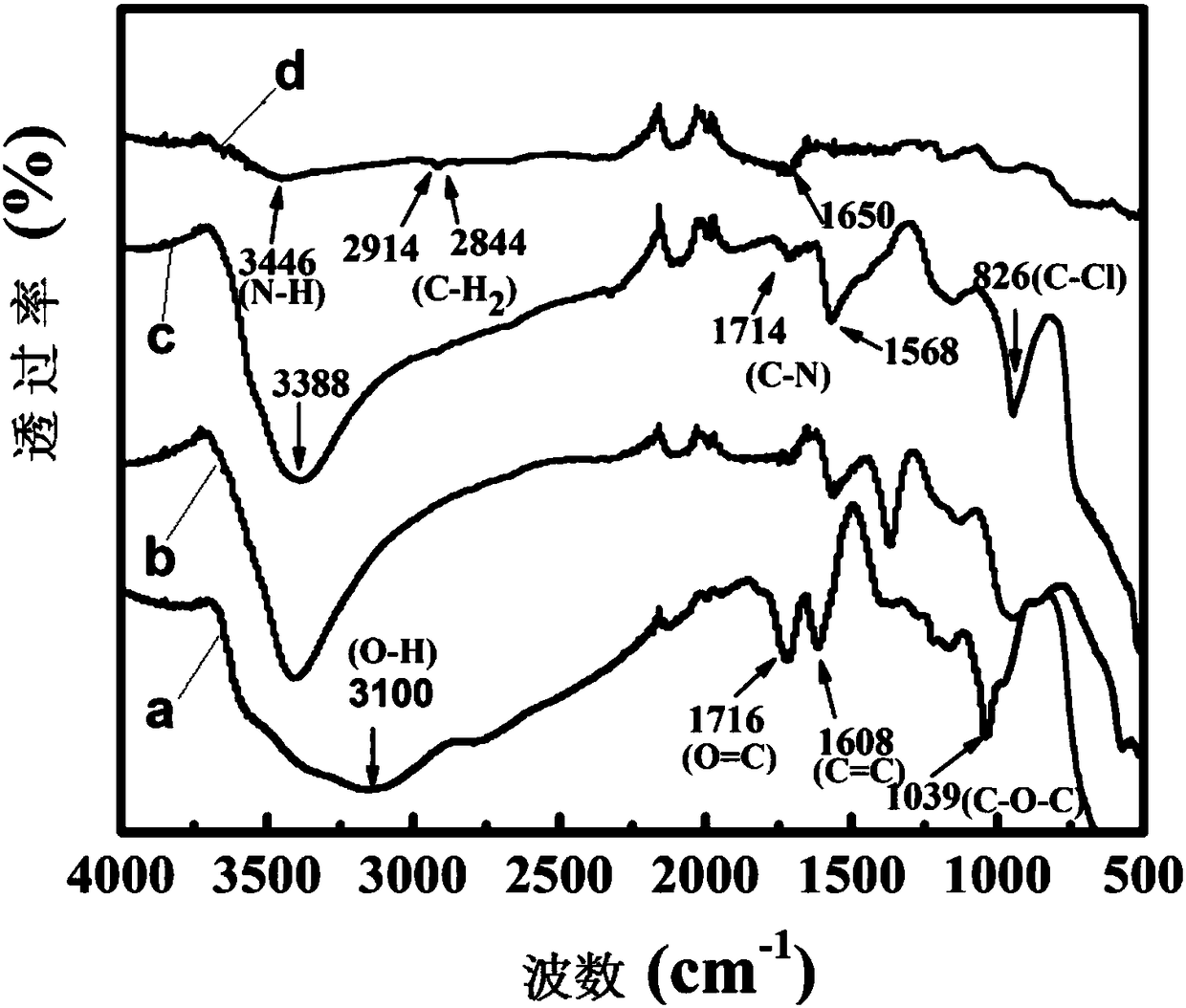

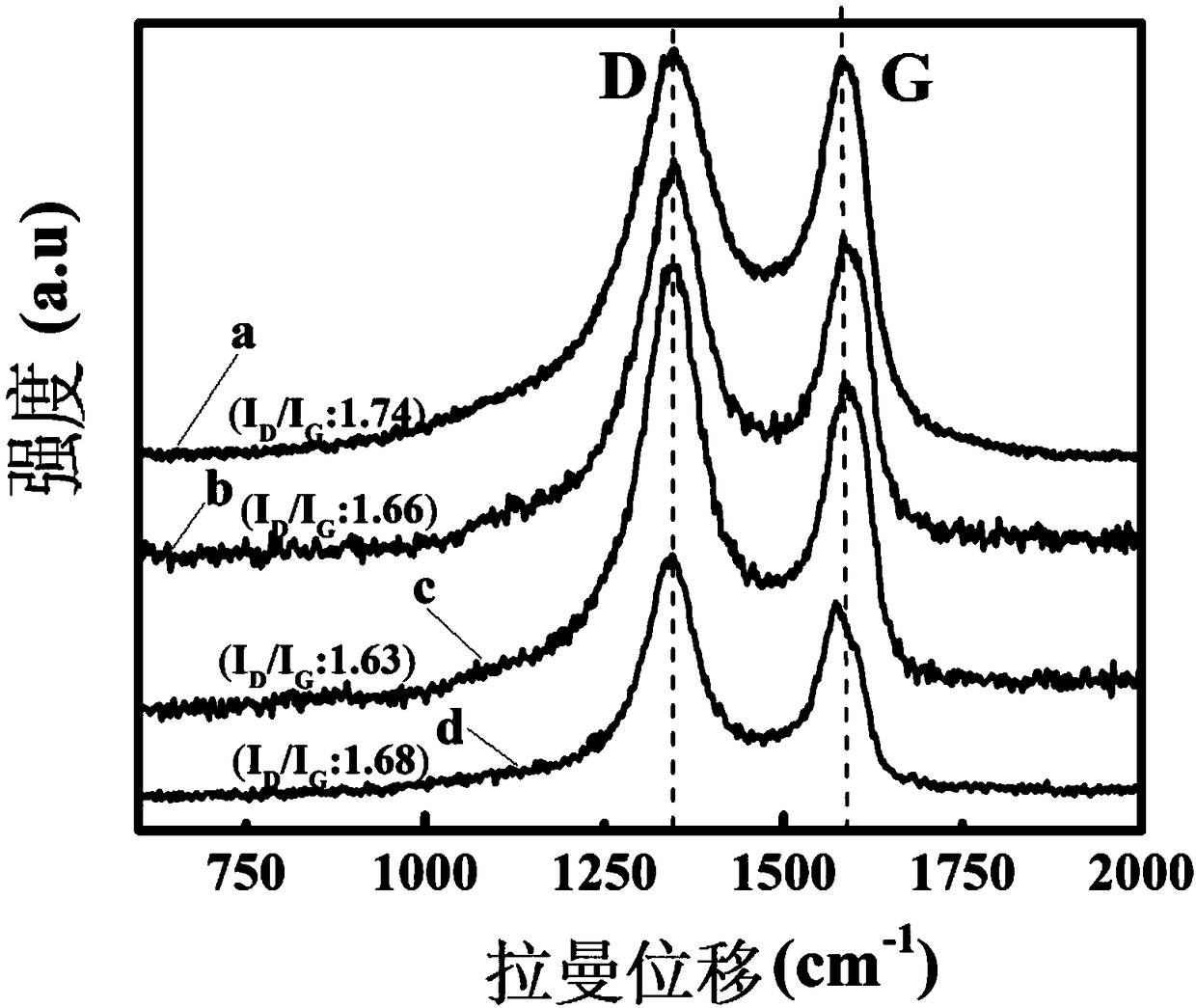

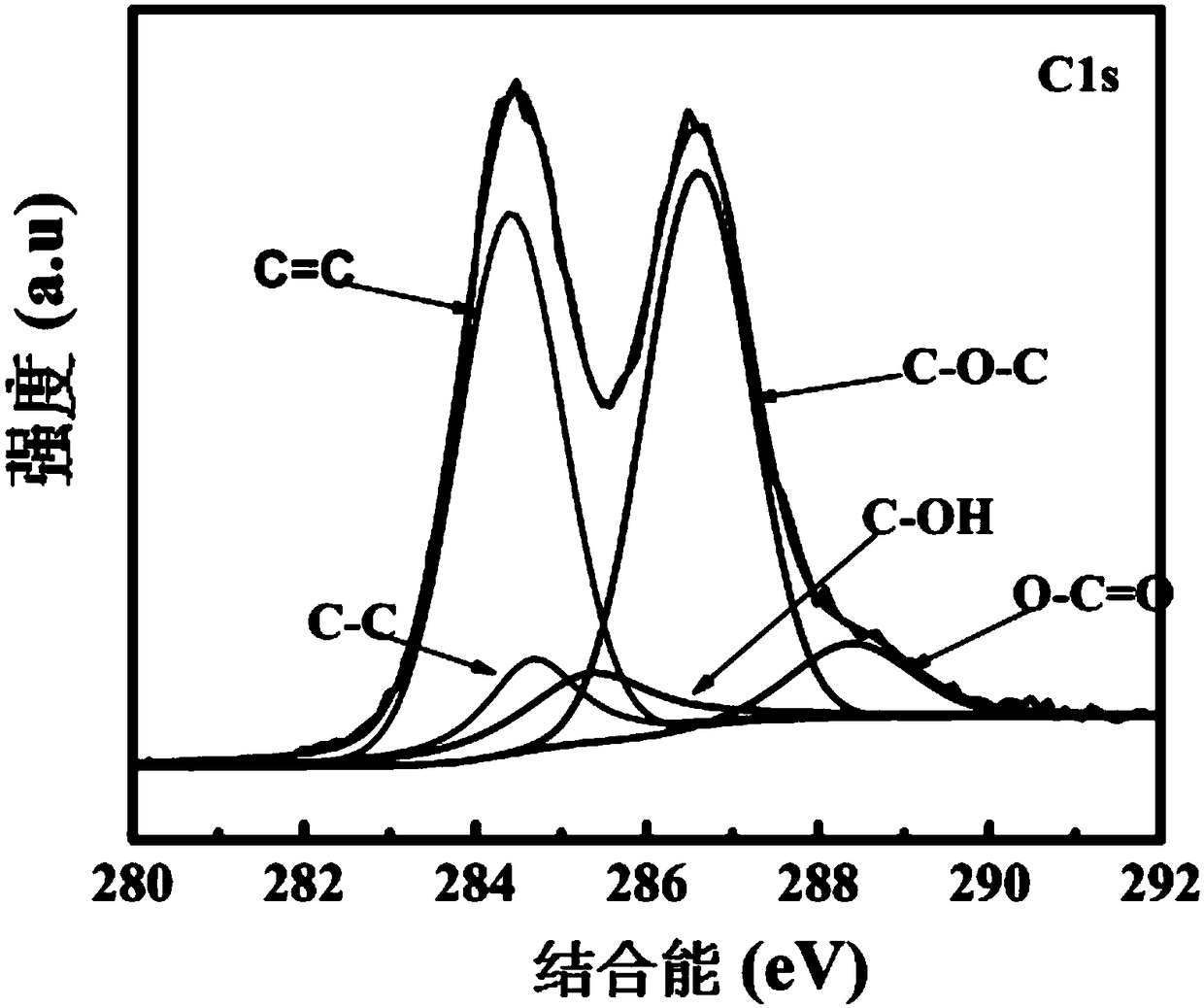

Method for chemical modification of surface of graphene oxide and application

InactiveCN108342099AStable chemical propertiesPlay a synergistic roleCarbon compoundsPigment treatment with non-polymer organic compoundsEpoxyDiethylenetriamine

The invention discloses a method for chemical modification of the surface of graphene oxide and application, and relates to a method for modification of the surface of graphene oxide and application.The problem that due to the fact that aggregation of graphene in epoxy resin is serious, the dispersity is poor, the interface bonding of a graphene / epoxy resin composite material is weak is solved. The method comprises the steps of 1, preparing graphene oxide; 2, performing hydroxylation processing on the graphene oxide; 3, modifying the graphene oxide through cyanuric chloride; 4, modifying thegraphene oxide through diethylenetriamine. The application is the application of a triazine derivative chemical modified graphene oxide in preparing the graphene oxide / epoxy resin composite material.The covalent grafting method is adopted, cyanuric chloride and diethylenetriamine are grafted to the surface of the graphene oxide, the triazine derivative modified graphene oxide is obtained, and thedispersity and the interface bonding performance of the graphene oxide in the composite material are improved. The method is used for chemical modification of the surface of the graphene oxide and preparation of the graphene oxide / epoxy resin composite material.

Owner:QINGDAO UNIV

Preparation method of flame-retardant waterborne polyurethane paint

ActiveCN104046224ABig smokeSmoke suppressionFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method of flame-retardant waterborne polyurethane paint. The preparation method comprises the steps of under action of a dibutyltin dilaurate catalyst, mixing 10-(2,5-dyhydroxyl phenyl)-9,10-dihydro-oxa-10-phosphaphenanthrene-10-oxide with hexamethylene diisocyanate, reacting for 1-4 hours at 90-110 DEG C, adding a nitrogen-phosphor compound into a reaction system to obtain polyurethane prepolymer, wherein a reaction temperature is 70-110 DEG C, and reaction time is 30-60 minutes; adding a chain extender and a butanone solvent into the polyurethane prepolymer, reacting for 2-5 hours at 60-85 DEG C, adding triethylamine to carry out neutralization reaction for 20-40 minutes, adding water to carry out emulsification to form waterborne polyurethane; adding manganese salt dispersion liquid, 5-hydroxytryptophane, hexachlorocyclotriphosphazene and gamma-diethylenetriamine propyl methyl dimethoxy silane into polyurethane, and shearing and stirring for 30-80 minutes under a condition with pH of 7 to obtain the flame-retardant waterborne polyurethane paint. Flame resistance and mechanical performances of the polyurethane are greatly improved.

Owner:广东顺德大地缘新材料有限公司

Homogeneous phase cation exchange film and preparation method thereof

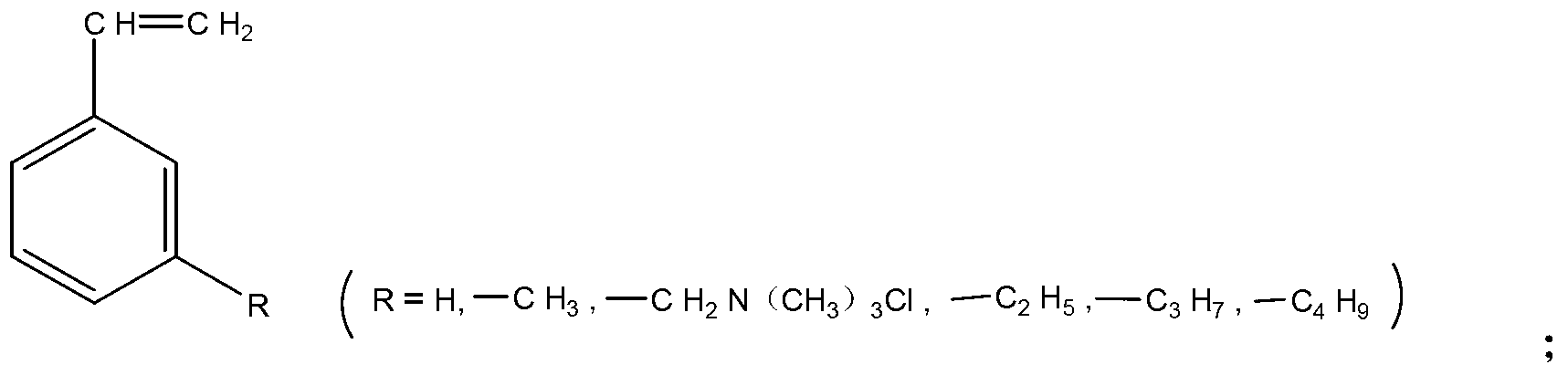

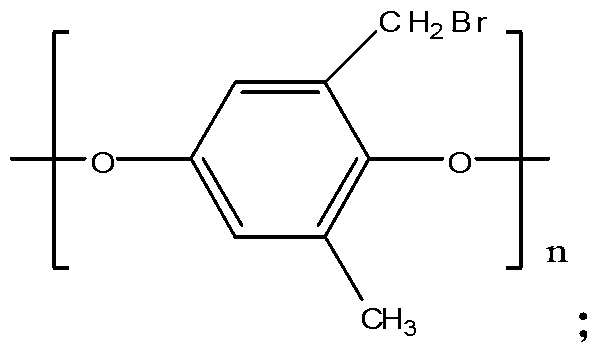

ActiveCN101352657AHigh strengthGood compatibilitySemi-permeable membranesBenzoyl peroxideSolvent free

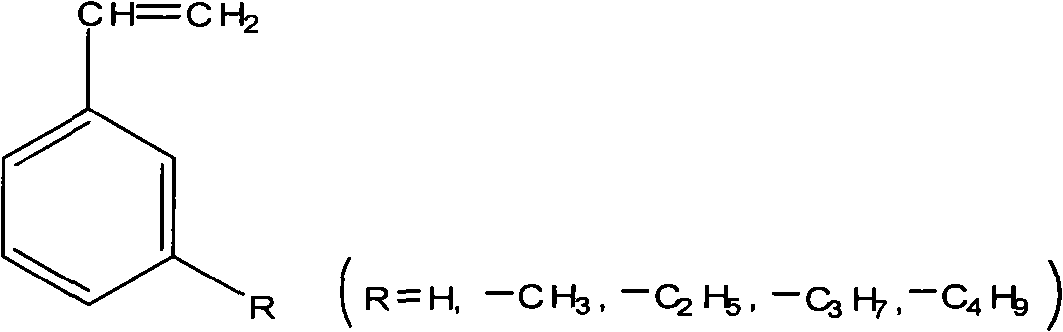

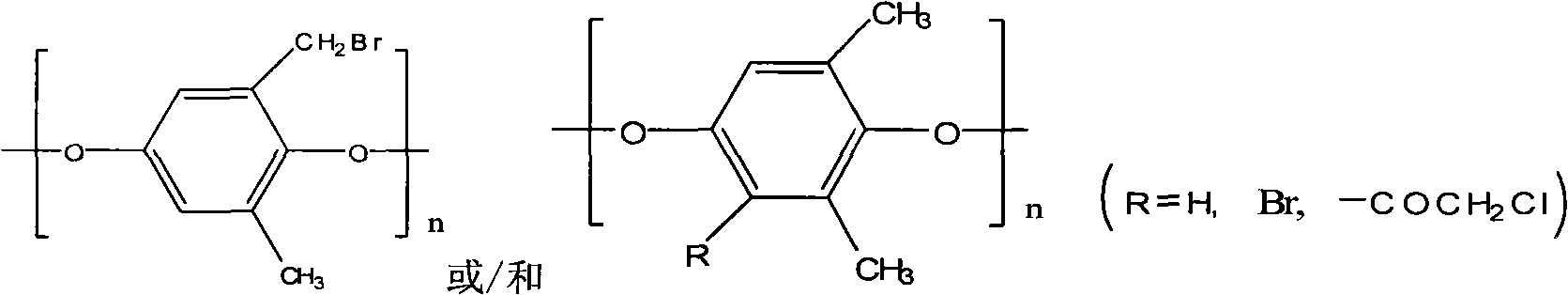

The invention relates to a homogeneous cation exchange membrane and a preparation method thereof, the homogeneous cation exchange membrane is characterized in that: cinnamene or / and alkyl cinnamene is taken as a monomer, divinylbenzene is taken as a crosslinking agent, benzoyl peroxide or / and azobisisobutyronitrile is taken as an initiator and bromomethyl or chloracetyl poly 1, 4-dimethyl-2, 6-phenylene oxide are taken as a polymer reinforcing agent to prepare even solution which is coated on a reinforced fabric for polymerization to obtain a base membrane which is then sulfonated in a mixture of concentrated sulphuric acid and chlorosufonic acid to obtain the homogeneous cation exchange membrane. Due to adopting aromatic polymer to produce a functional group by further sulfonation, the cation exchange membrane obtained has high exchange capacity, excellent electrochemical property and even structure. In addition, as the monomer used as the solvent can be polymerized, the preparation method is a green solvent-free technology. The cation exchange membrane series with different structures and functions can be obtained by regulating the content of polymer and crosslinking degree and changing the categories of supporters and the sulfonation condition.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

Curable resin composition

ActiveUS7595362B2Maintain good propertiesIncrease resistanceSynthetic resin layered productsMicaSolventStructural unit

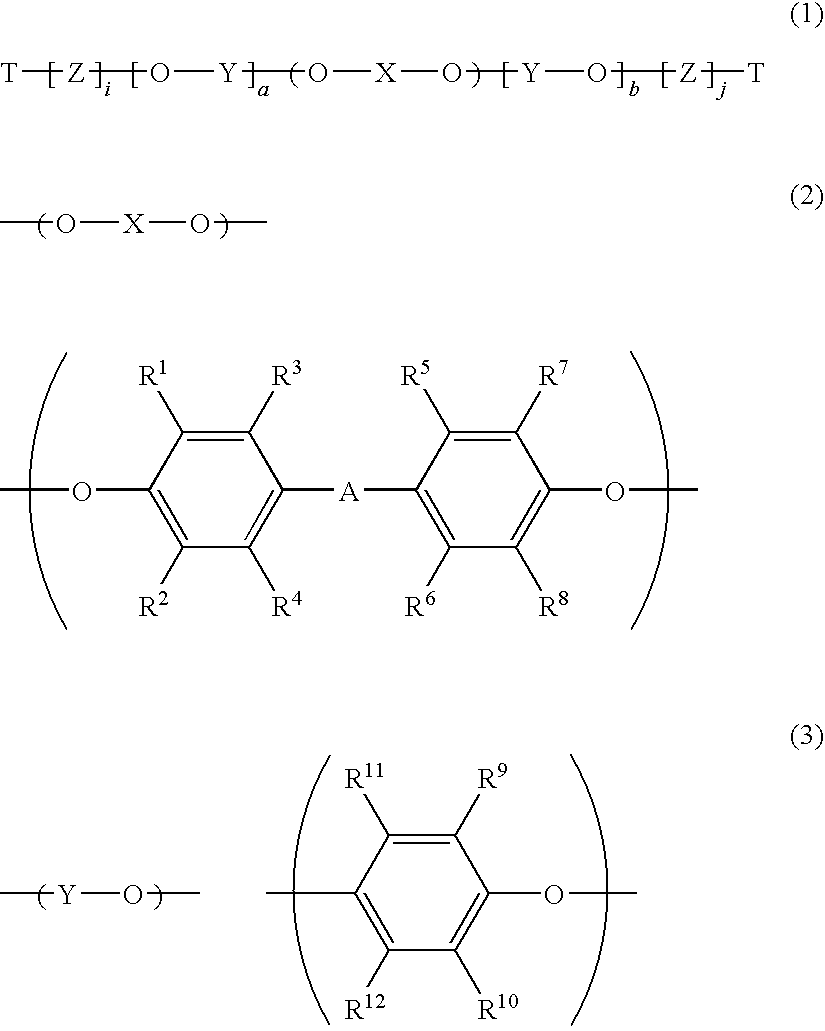

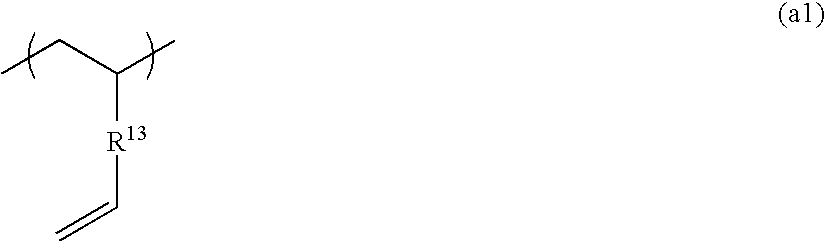

Provided is curable resin composition which gives a cured article excellent in chemical resistance, dielectric properties, low water-absorption, heat resistance, flame retardance, and mechanical properties and which is usable in applications such as dielectric materials, insulating materials, heat-resistant materials, and structural materials. The curable resin composition includes a component (A) which is a polyphenylene ether oligomer having a number-average molecular weight of 700 to 4,000 and having a vinyl group at both end and a component (B) which is a solvent-soluble polyfunctional vinylaromatic copolymer which has structural units derived from monomers including a divinylaromatic compound (a) and an ethylvinylaromatic compound (b) and in which the content of repeating units derived from the divinylaromatic compound (a) is 20 mol % or higher, the ratio of the amount (wt. %) of the component (A) to that (wt. %) of the component (B) being (20 to 98):(2 to 80). The composition can further contain a layered silicate, a halogenated flame retardant, etc.

Owner:NIPPON STEEL CHEMICAL CO LTD

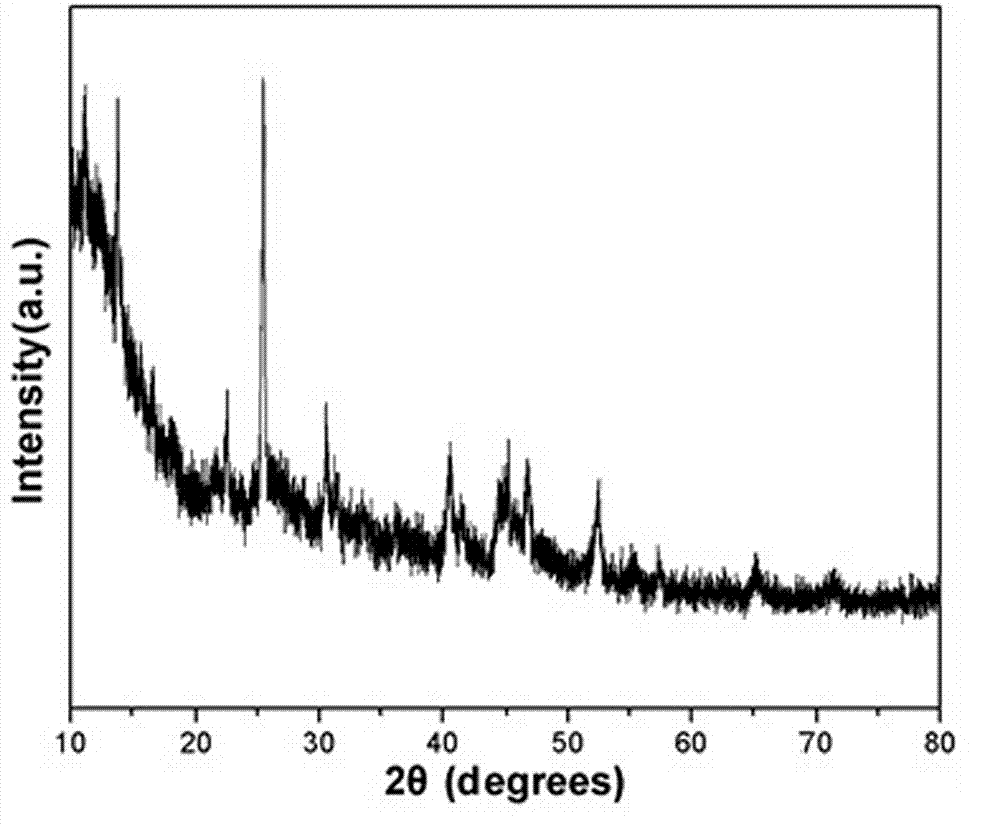

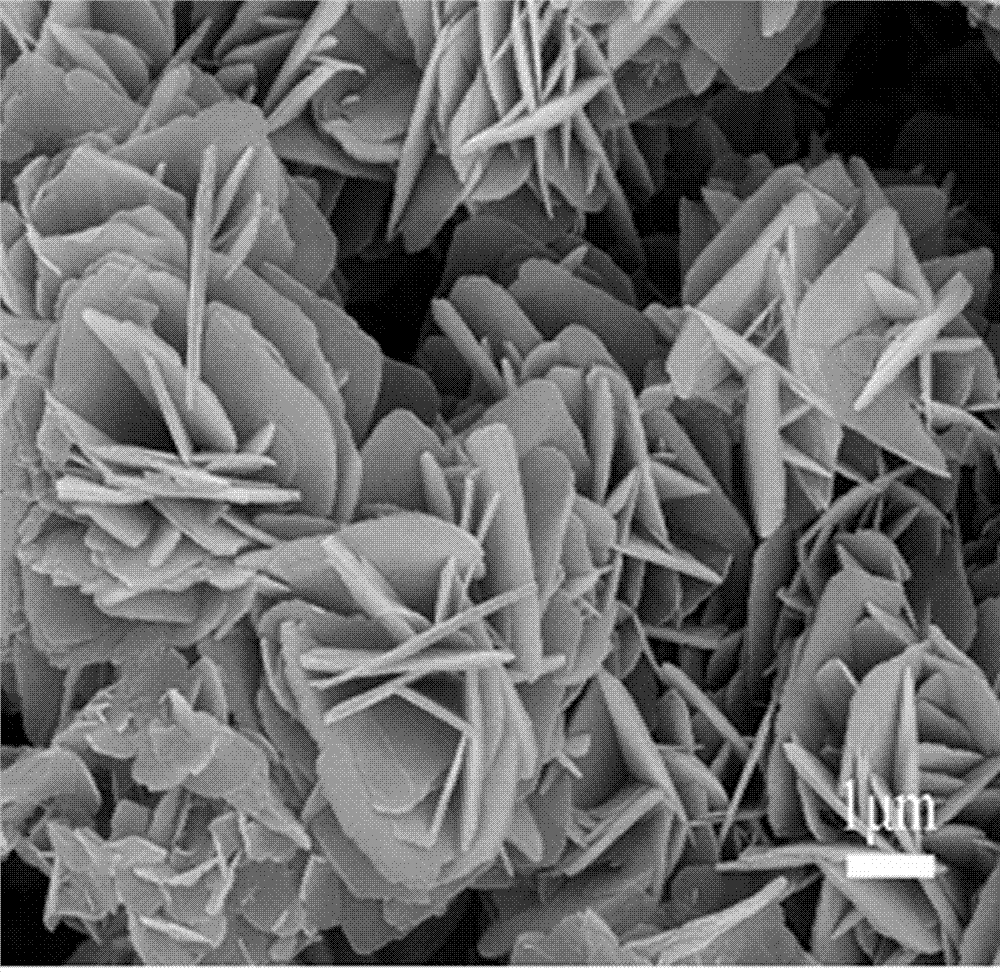

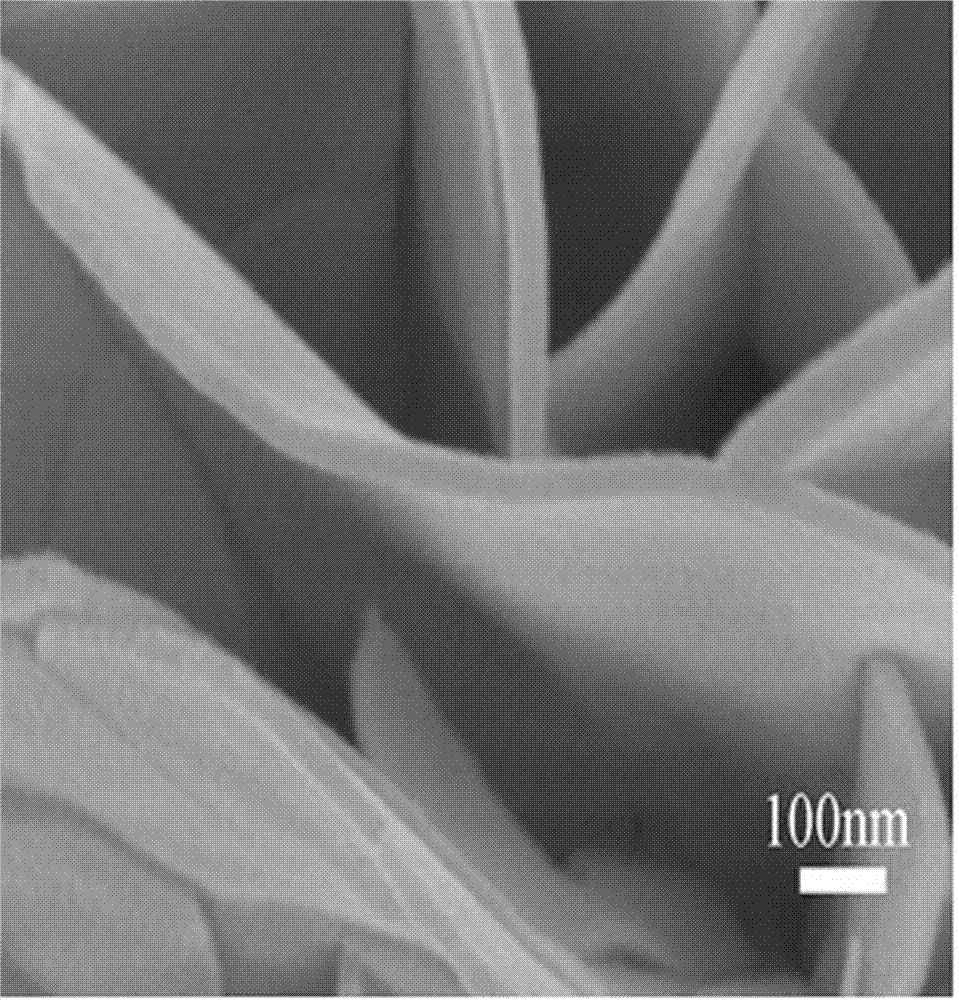

Method for synthesizing nano flower-shaped spherical In2Se3 diethylenetriamine (DETA) hybrid material by means of solvothermal

ActiveCN102849687AHigh crystallinityIncrease productionMaterial nanotechnologySelenium/tellurium compundsIndiumDiethylenetriamine

The invention belongs to the technical field of synthesis of photoelectric semiconductor nano materials, and relates to an inorganic-organic hybrid material synthesis method, in particular to a method for synthesizing nano flower-shaped spherical In2Se3 diethylenetriamine (DETA) hybrid material by means of solvothermal. The method includes: using indium salt and selenium powder as reactants, using diethylenetriamine (DETA) and ethylene glycol (EG) as solvents, reacting in a reaction kettle with a polytetrafluoroethylene lining through solvothermal, washing, separating, and performing vacuum drying to obtain the hybrid material. Deducing on a growing mechanism, the method is suitable for synthesis of other inorganic-organic hybrid materials. The prepared nano flower-shaped spherical In2Se3(DETA) consists of a large-area three-dimensional flower-shaped structure, each flower is 2-3 micrometers in diameter and formed by rectangular nano sheets which are radiated around through one point, the nano sheets are smooth in surface and about 30nm in thickness, and the flower-shaped structure is free of agglomeration, fine in dispersibility and high in crystallinity. The method for synthesizing nano flower-shaped spherical In2Se3(DETA) hybrid material by means of solvothermal is environment-friendly, simple in operation, high in controllability, low in cost, high in crystallinity of obtained products, and high in yield.

Owner:指南者品牌管理(苏州)有限公司

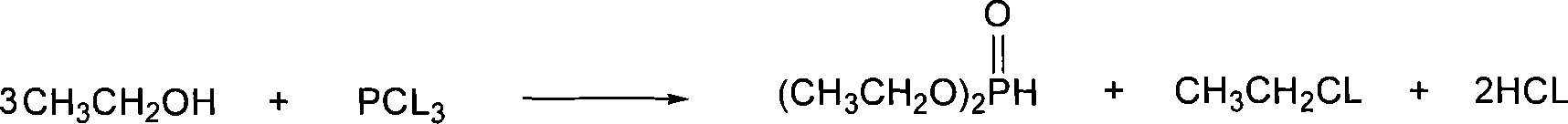

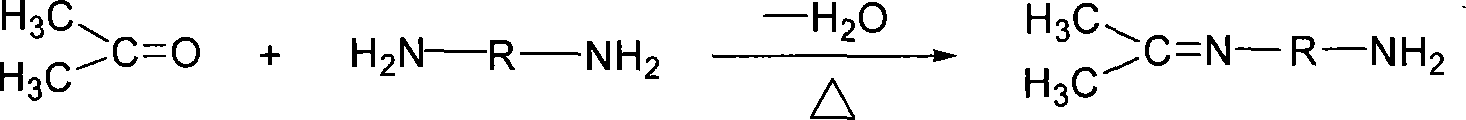

Organic phosphorus active flame-proof epoxy resin curing agent amine group phosphonate and preparation method thereof

The invention discloses an organophosphorus active flame-proof epoxide resin solidifying agent amino phosphonate ester and the preparing method. The amino phosphonate ester comprises the following parts: 3:1:1:1 absolute ethyl alcohol, phsophorus trichloride, organic amine (the structural formula is H2N-R-NH2)and acetone. The organic amine is diethylenetriamine, triethylene tetraamine, tetraethylene pentamine or 4, 4-diaminodiphenylmethane. The method comprises the following steps: 1, synthesizing diethyl phosphate with alcohol and phsophorus trichloride; 2, generating ketoimine with acetone and the organic amine by adding the anhydrating agent; 3, generating amino phosphonate with diethyl phosphate and ketoimine. The oxygen index of the product is more than 20 and less than 34.6. The invention is provided with the simple method and the simple operation.

Owner:HEILONGJIANG INST OF PETROCHEM

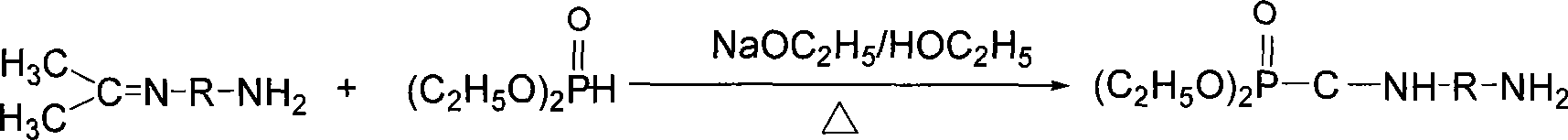

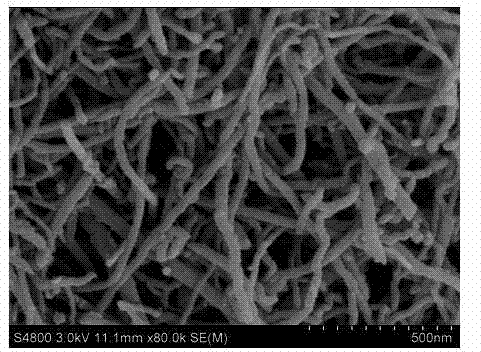

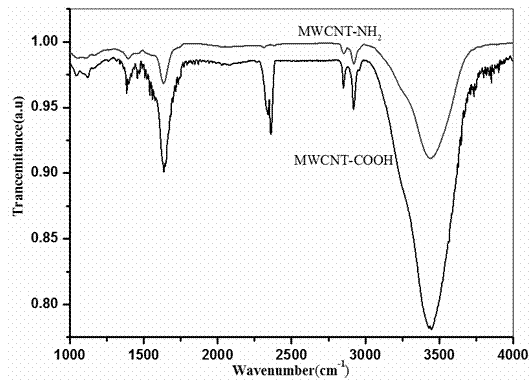

Preparation method of modified multi-wall carbon nano-tube material

ActiveCN104845381AImprove organic compatibilityGood interface fastnessChemical analysis using titrationElastomerPolymer science

The invention provides a preparation method of a modified multi-wall carbon nano-tube material. The preparation method takes N,N-methylene bisacrylamide (MBA) and diethylenetriamine (DETA) as raw materials and adopts a Michael addition method for a one-step method to synthesize a golden yellow viscous liquid terminated amino hyperbranched polymer (NH2-HBP). The preparation method comprises the following steps: weighing a certain amount of NH2-HBP and putting into a three-opening flask; adding ultrapure water and completely dissolving; then adding a certain amount of terminated carboxyl carbon nano-tubes into a water bath at 45-55 DEG C; reacting for 3-5 hours at a stirrings peed of 20r / min-30r / min; then drawing and filtering to obtain modified multi-wall carbon nano-tubes; repeatedly washing the modified multi-wall carbon nano-tubes by the ultrapure water for a plurality of times; and drying at 60 DEG C to obtain the multi-wall carbon nano-tubes subjected to terminated amino hyperbranched grafting and modification. The tube walls of the grafted and modified terminated amino hyperbranched multi-wall carbon nano-tubes have a lot of amino so that the product has very good water solubility and solvent solubility; the modified multi-wall carbon nano-tube material can be used as a very good additive and can be dispersed into polymers including a polyurethane coating, a rubber elastic body, functional plastic and the like very well so that the foundation is provided for obtaining a uniform modified multi-wall carbon nano-tube polymer composite material, and the application prospect is wide.

Owner:SHAANXI UNIV OF SCI & TECH

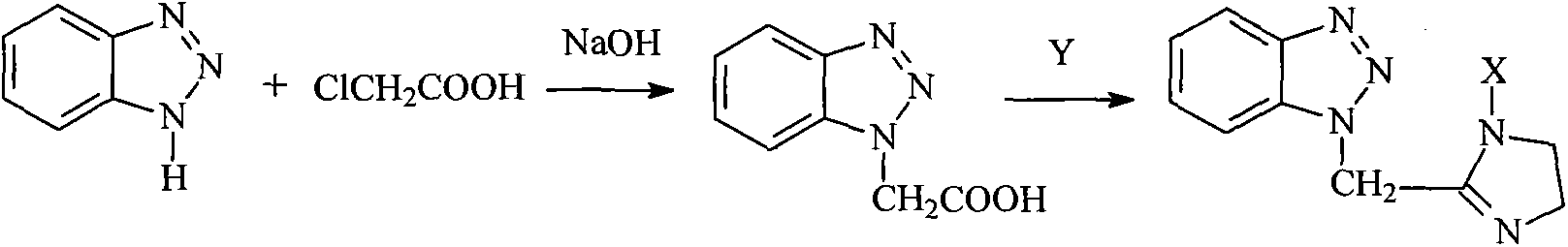

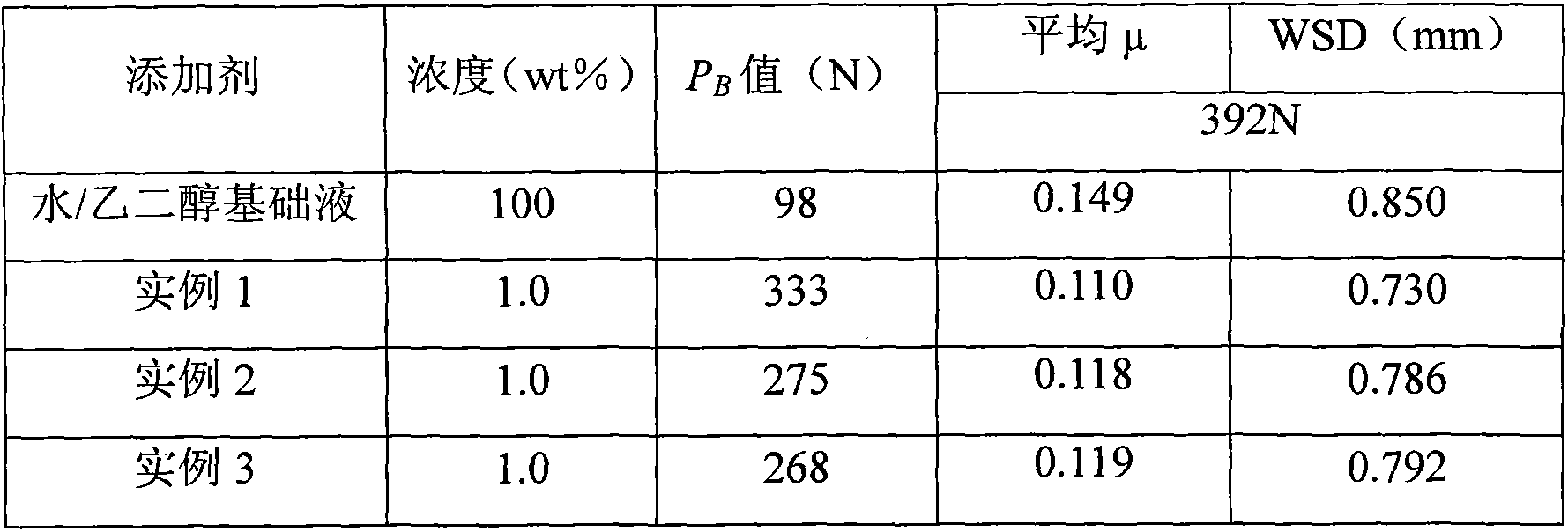

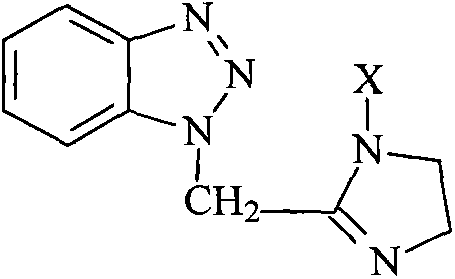

Water-soluble benzotriazole imidazoline extreme-pressure anti-wear reagent and preparation method thereof

ActiveCN104327054ACorrosion resistanceGood water solubilityOrganic chemistryAdditivesWater basedReaction temperature

The invention relates to a synthetic process of a benzotriazole derivative containing an imidazole group. By taking benzotriazole as a raw material, the synthetic process comprises the steps of reacting benzotriazole with chloroacetic acid to obtain benzotriazole acetic acid; and sequentially reacting benzotriazole acetic acid with diethylenetriamine, N-hydroxy ethanediamine, ethanediamine, triethylene tetramine and tetraethylenepentamine, wherein dimethylbenzene or toluene is used as a water carrying agent, the molar ratio of benzotriazole acetic acid to the amine including diethylenetriamine and N-hydroxy ethanediamine is 1 to 1.1, the reaction temperatures are 130-160 DEG C and 180-220 DEG C, and the reaction time is about 4 hours and about 2 hours. The synthetic process is simple to operate and high in yield, and reaction conditions are easy to control. The product, namely the benzotriazole imidazoline derivative, can be applied to water-based lubricating liquid, a copper corrosion inhibitor, an anti-rust agent and the like.

Owner:新疆金雪驰科技股份有限公司

Composite material for dental prosthesis and preparation method of composite material

InactiveCN105232340AHigh mechanical strengthHigh strengthImpression capsDentistry preparationsBiocompatibilitySILICONE DIOXIDE

The invention discloses a composite material for dental prosthesis and a preparation method of the composite material. The composite material is prepared from the following components in parts by weight: 20-40 parts of polyethylene, 25-40 parts of xanthan gum, 20-25 parts of hydroxy calcium phosphate, 2-8 parts of chitosan, 1-6 parts of tributyl citrate, 4-8 parts of a phase transfer agent, 2-6 parts of divinyl tetramine, 25-35 parts of 2-methyl-2-propenoic acid 2-(phosphonooxy) ethyl ester, 4-8 parts of silver lactate, 7-20 parts of titanium dioxide, 10-15 parts of silicon dioxide, 3-8 parts of an antioxidant, 4-8 parts of hydroxyanisole, 1-13 parts of calcium fluophosphate, 8-23 parts of ethanol and 25-45 parts of double distilled water. The tooth filling material disclosed by the invention is good in mechanical strength, high in intensity and good in biocompatibility, and the safety of the material to human bodies is improved. The preparation method disclosed by the invention is simple and easy to implement, and is suitable for industrial production.

Owner:SUZHOU COSMETIC MATERIALS

Super-early-strength fluoride-free alkali-free liquid accelerator and preparation method thereof

ActiveCN113603384AHigh aluminum contentAvoid hydrolysisSolid waste managementOXALIC ACID DIHYDRATEDiethylenetriamine

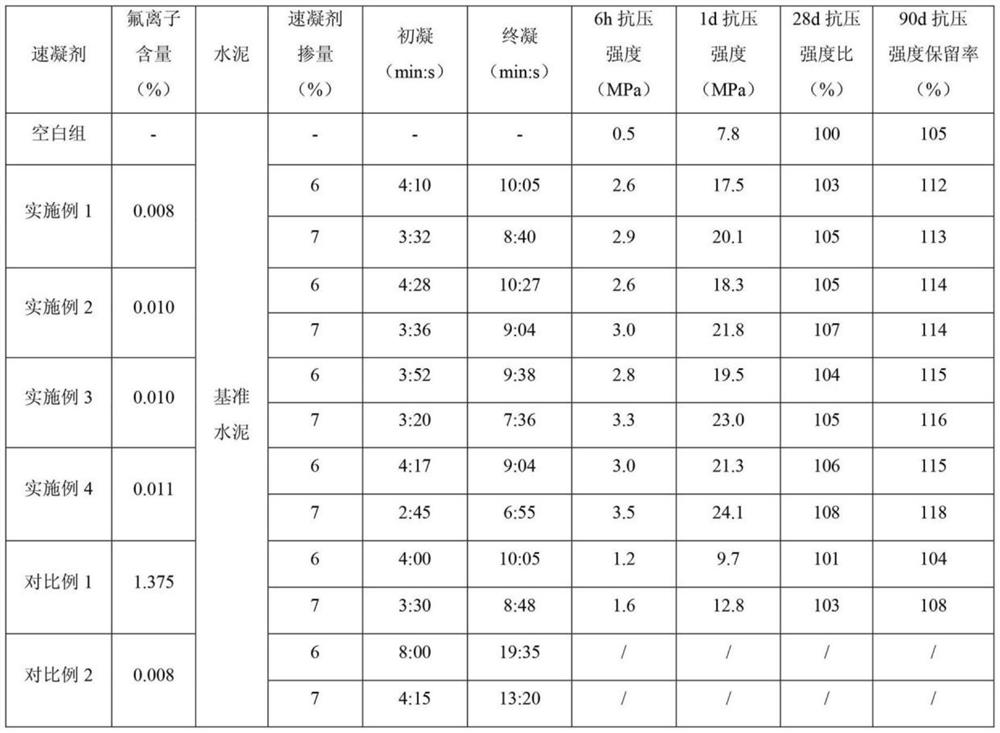

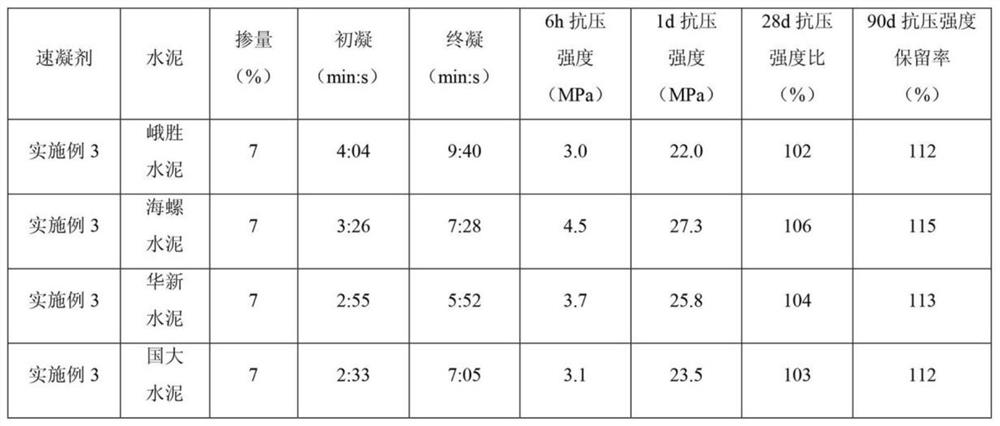

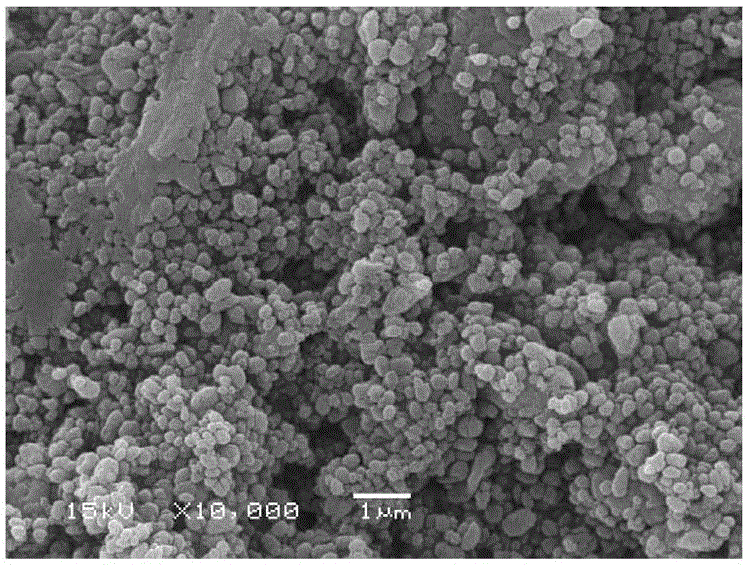

The invention relates to a super-early-strength fluorine-free alkali-free liquid accelerator and a preparation method thereof. The accelerator is prepared from the following raw materials: aluminum sulfate, an organic dissolution promoter, a stabilizer, an early strength agent, a pH regulator and water. The organic dissolution promoter is formed by mixing a component A, a component B and a component C, wherein the component A is monoethanolamine, diethanolamine or triethanolamine; the component B is N-methyldiethanolamine, N,N-dimethylethanolamine or N,N-dimethylformamide; and the component C is diethylenetriamine, triethylene tetramine or tetrahydroxypropyl ethylenediamine. The stabilizer is selected from superfine sepiolite and pseudo-boehmite. The pH regulator is selected from p-toluenesulfonic acid, oxalic acid and formic acid. The early strength agent is selected from lithium sulfate, magnesium sulfate, nanometer silica sol and nanometer aluminum sol. The super-early-strength fluorine-free alkali-free liquid accelerator is good in performance, simple in preparation process, free of fluorine, alkali and chlorine and capable of meeting the performance requirements of various setting accelerator standards for alkali-free accelerators; and according to the liquid accelerator, compressive strength within 6 hours is far larger than 2.5 MPa, compressive strength within 1 day is far larger than 15.0 MPa, a compressive strength retention rate within 90 days is larger than or equal to 110%, and stability exceeds 9 months.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

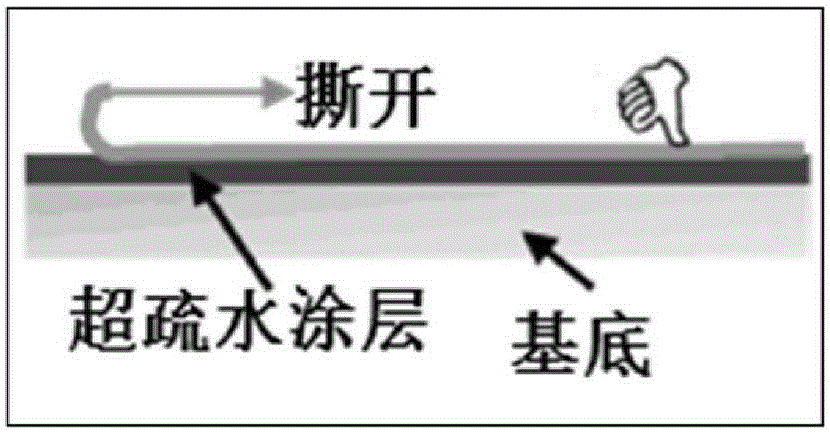

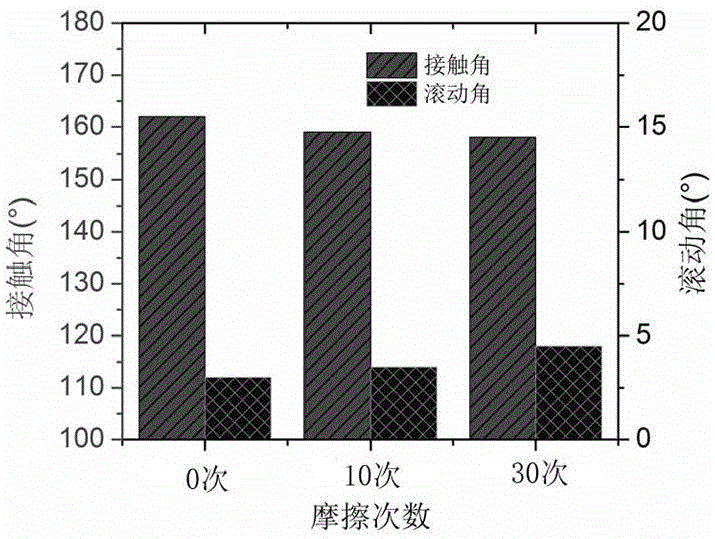

Fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and preparation method and utilization method thereof

ActiveCN105885564AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsPolyether coatingsPolymer scienceCoating system

The invention discloses a fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and a preparation method and a utilization method thereof. The coating comprises a coating system and a curing agent; the coating system comprises epoxy resin, polytetrafluoroethylene particles, polyperfluoromethyl isopropyl ether and an organic solvent; the curing agent is prepared by reaction of diethylenetriamine and perfluorobutyric acid. The preparation method includes preparation of the coating system and preparation of the curing agent. The utilization method includes: dissolving the curing agent into a diluent, adding an obtained curing agent solution into the coating system, well mixing, coating to a required surface and curing. The fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating has advantages of excellent super-hydrophobic property, favorable abrasion resistance, water impact resistance, corrosion resistance, high adhesive power, wide application range and the like. The preparation method is simple and easy to implement and suitable for large-scale application.

Owner:NAT UNIV OF DEFENSE TECH

Stable and efficacious soft solid product

InactiveUS6986885B2Improve efficacyImprove stabilityCosmetic preparationsToilet preparationsPolymer scienceActive agent

A low residue antiperspirant and / or deodorant composition in the form of an anhydrous, surfactant-free and antiseptic alcohol-free suspension exhibiting a syneresis of less than 8% is disclosed which comprises: (a) a dimethicone / vinyldimethicone crosspolymer composition made by reacting a polymethylhydrogensiloxane with an alpha, omega-divinylpolydimethyl siloxane for which the dimethicone / vinyldimethicone crosspolymer composition is used at a concentration of 0.5–10% in cyclomethicone; (b) polyethylene beads having a density in the range of 0.91–0.98 grams / cm3 and a particle size in the range of 5–40 microns, wherein the polyethylene beads are used in an amount of at least 2% by weight based on the total weight of the composition; (c) a volatile silicone; (d) an emollient or mixture of two or more emollients; and (e) an effective amount of an antiperspirant active material.

Owner:COLGATE PALMOLIVE CO

Multimodal polyethylene composition obtainable with high activity catalyst

The present invention concerns a multimodal, preferably bimodal, polyethylene (PE) composition comprising a base resin which comprises (A) a first ethylene homo- or copolymer fraction, and (B) a second ethylene homo- or copolymer fraction, wherein (i) fraction (A) has a lower weight average molecular weight than fraction (B), (ii) the base resin has an MFR 5 of at least 0.01 g / 10 min and (iii) the base resin is obtainable by polymerising ethylene and optionally at least one comonomer in the presence of a catalyst having an overall activity of at least 30 kg polymer per g catalyst. Furthermore, the present invention relates to a process for the production of such a composition as well as to the use of such a composition for the production of articles.

Owner:ボレアリステクノロジーオイ

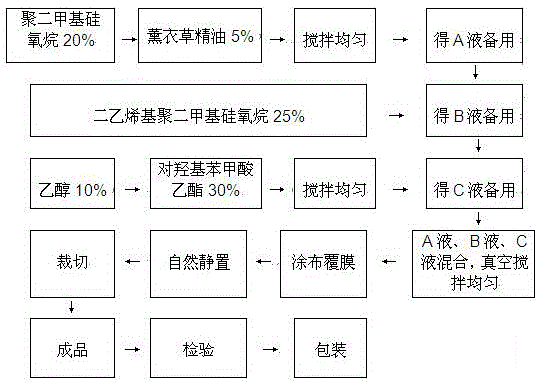

Scar sheet and preparation technology thereof

InactiveCN105055377AEasy to useStrong adhesionDermatological disorderSheet deliveryAdditive ingredientMedicine

The invention relates to a scar sheet. The scar sheet comprises a silica gel paster and an anti-adhesion film, wherein the silica gel paster comprises a backing layer and a gel layer; the gel layer is a mixture of lavender essential oil, divinyl polydimethyl siloxane, polydimethyl siloxane and ethyl-p-hydroxybenzoate; the backing layer is a silicone rubber film; the anti-adhesion film is a PE (polyethylene) film or release paper coated with silicon oil; the outer surface of the anti-adhesion film is covered with a waterproof plastic film. The scar sheet can be directly attached to a scar and is convenient to use; the silicone rubber backing layer has high adhesive force and is not prone to fall off; an enhancing layer is further arranged between the backing layer and the gel layer, so that a product has good durability; multiple medical ingredients are added to the gel layer and can effectively prevent wound infection, and the scar softening, flattening and fading time is shortened.

Owner:蚌埠崇迪生物科技有限公司

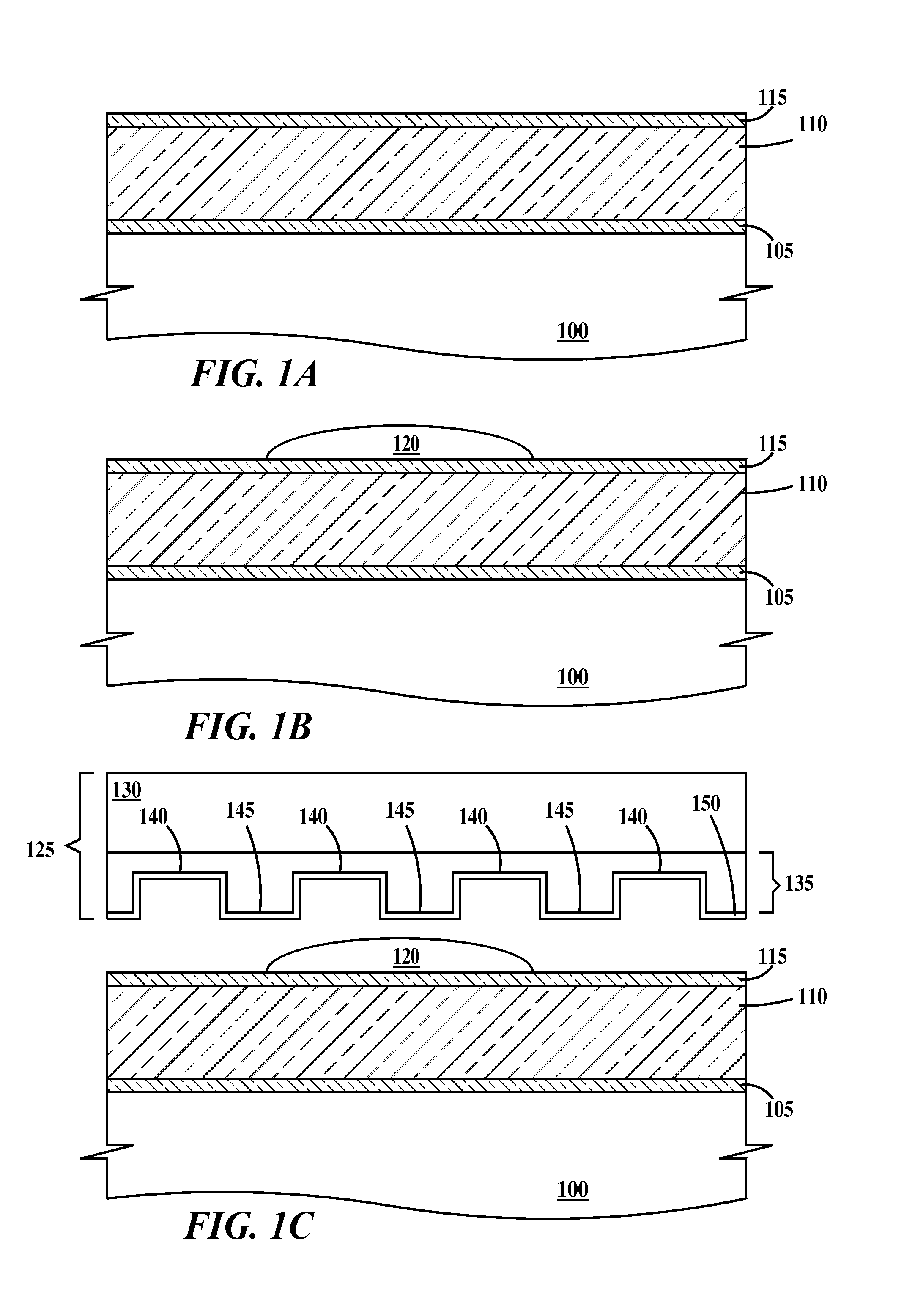

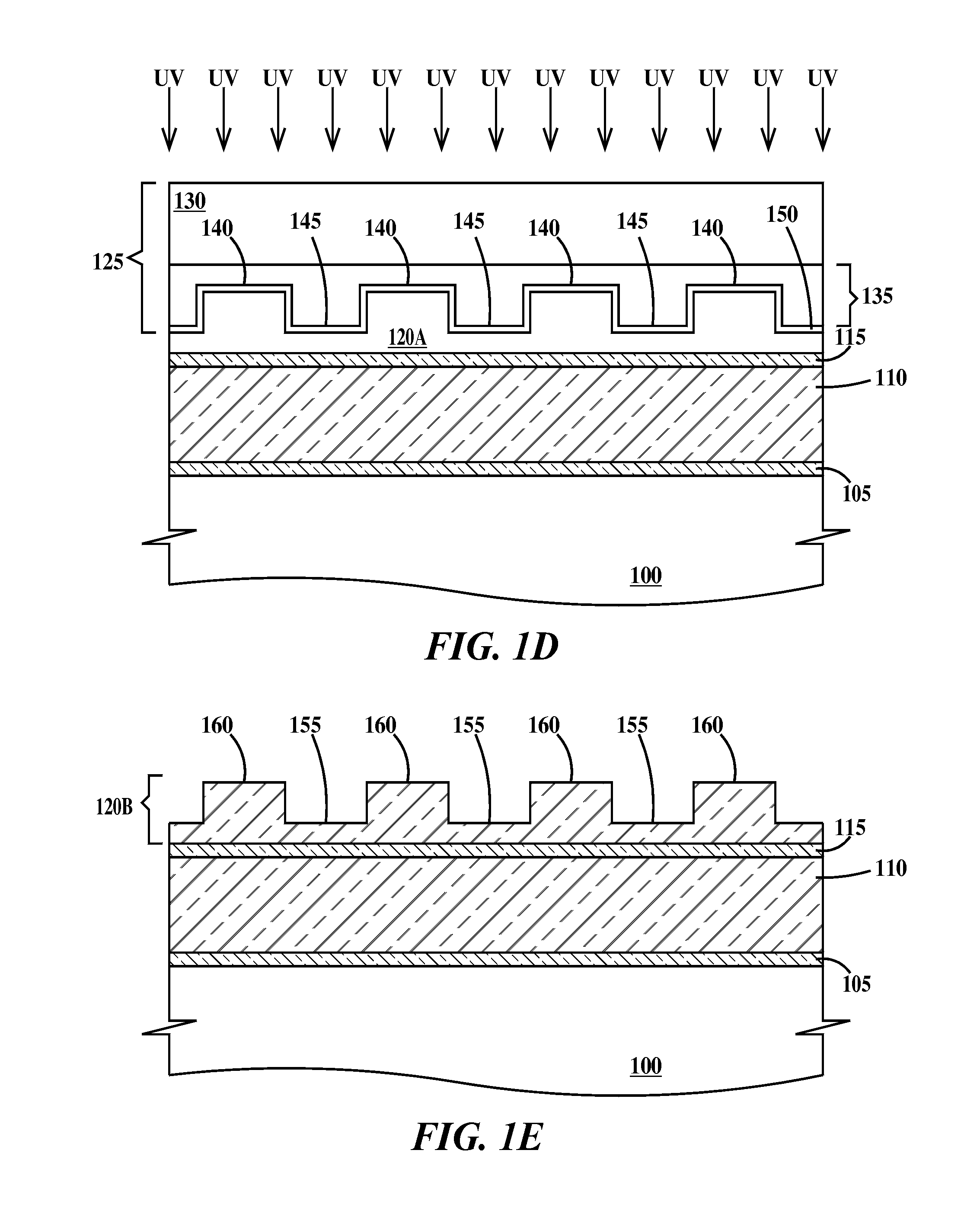

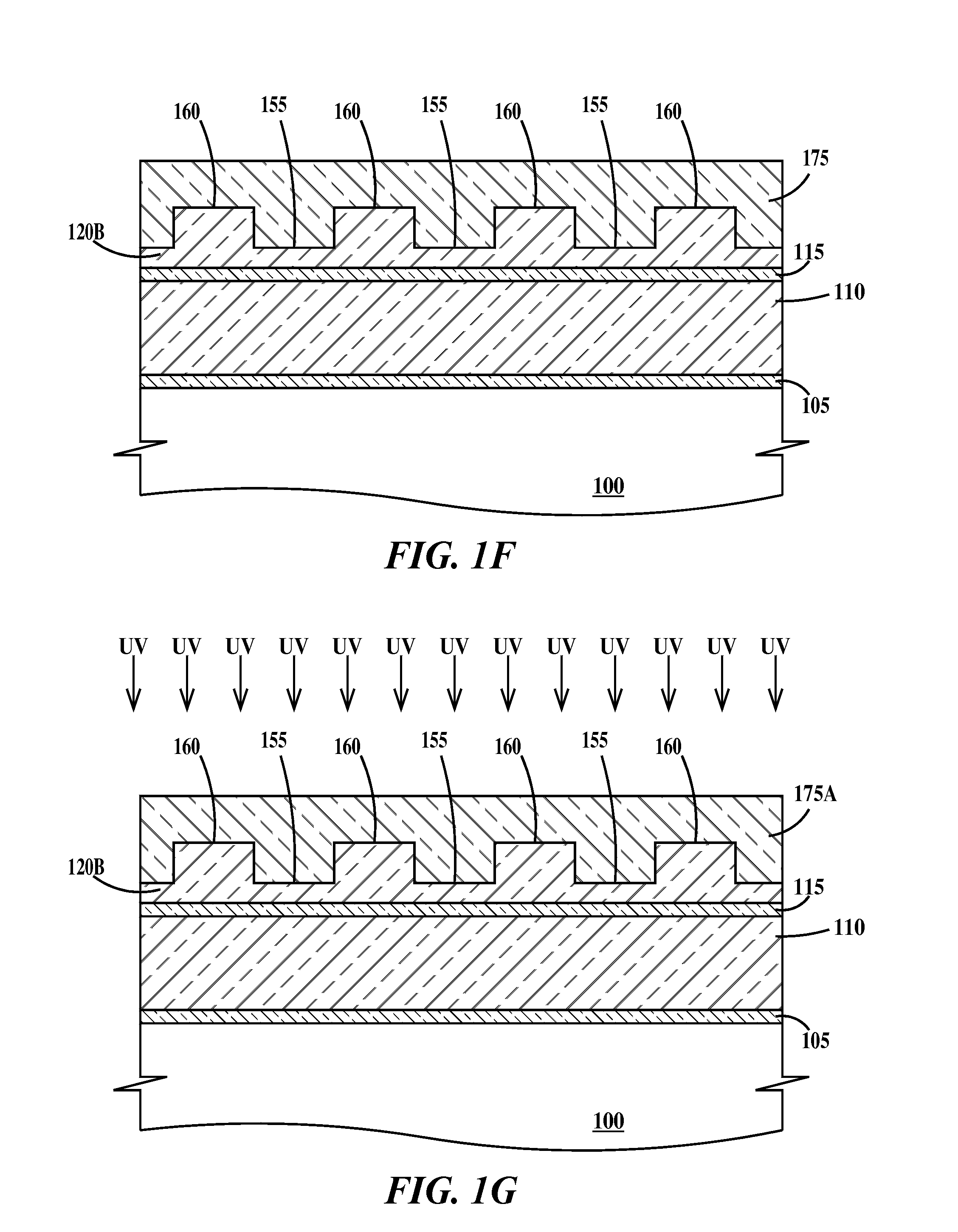

Aromatic vinyl ether based reverse-tone step and flash imprint lithography

A molding composition and a method of forming an pattern. The method includes forming on a substrate a molding layer of a molding composition of aromatic divinyl ethers; pressing the template into the molding layer, the template having a relief pattern, the molding layer filling voids in the relief pattern, the template not contacting the substrate; exposing the molding layer to actinic radiation, the actinic radiation converting the molding layer to a cured molding layer having thick and thin regions corresponding to the relief pattern; removing the template; filling the thin regions of the relief pattern with a backfill material; removing regions of the molding layer not protected by the backfill material to expose regions of the substrate; forming trenches in the exposed regions of the substrate; and removing any remaining molding layer and backfill material. A transfer layer may be used between the molding layer and the substrate.

Owner:TAIWAN SEMICON MFG CO LTD

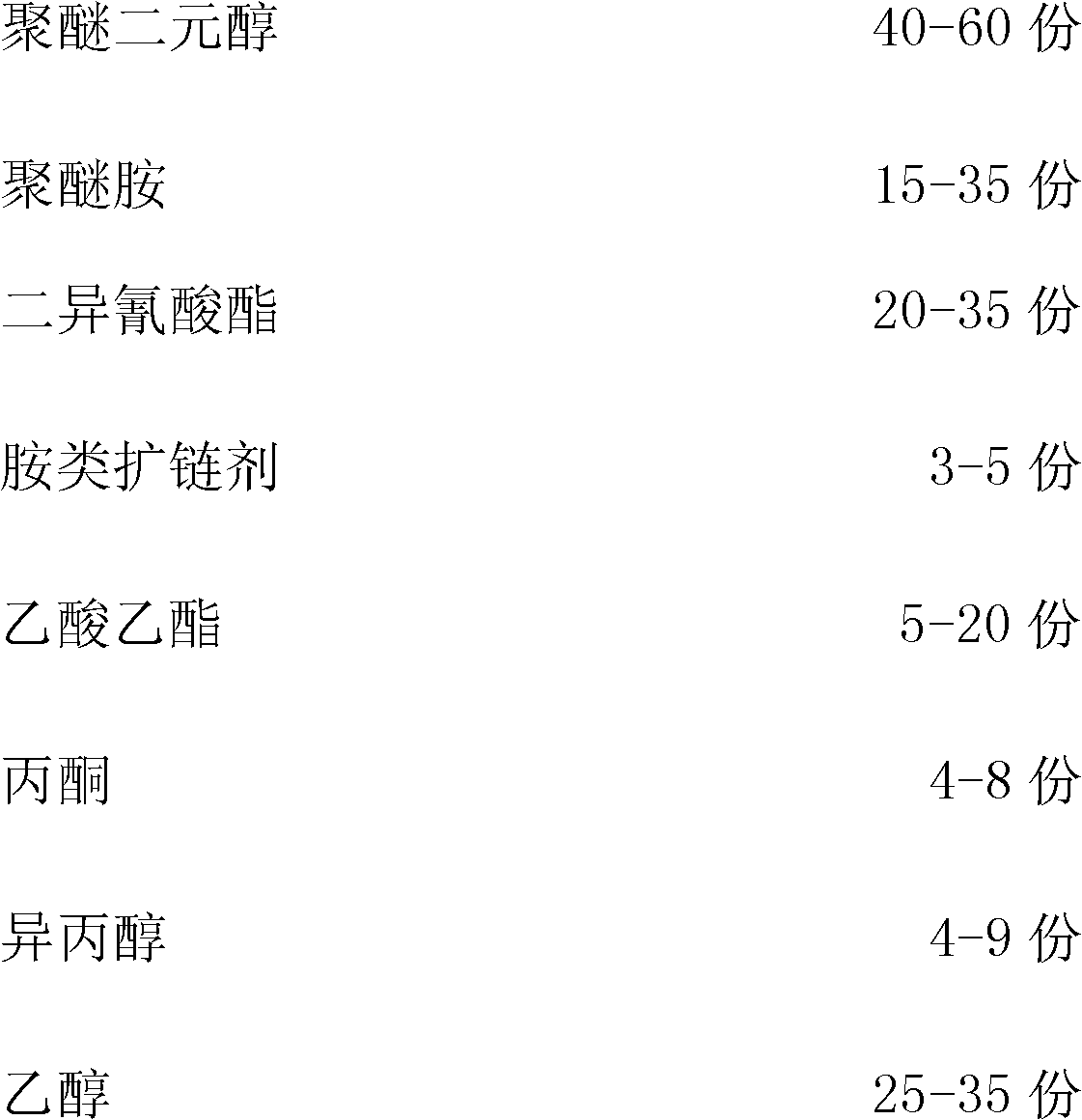

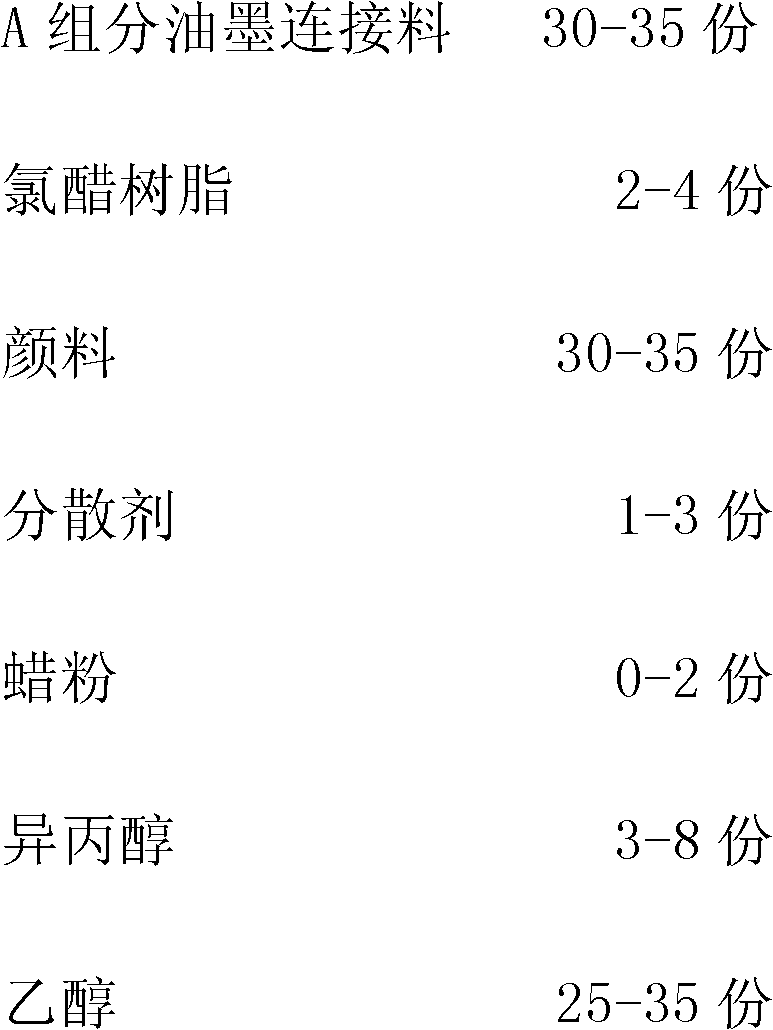

Bi-component high-temperature resistant alcohol-soluble ink binder, preparation method and application thereof

The invention relates to a bi-component high-temperature resistant alcohol-soluble ink binder, as well as a preparation method and the application of the bi-component high-temperature resistant alcohol-soluble ink binder, belonging to the technical field of ink binders. The bi-component high-temperature resistant alcohol-soluble ink binder comprises a component A and a component B which are separately stored, wherein the component A contains amino-terminated polyurethane prepolymer solution; and the component B is epoxy resin alcohol solution modified by amino silane coupling agent. The preparation method of the alcohol-soluble ink binder comprises the following steps of: carrying out vacuum dehydration on polyether diol until the water content is less than 0.08%; cooling to 40-45 DEG C; sequentially adding ethyl acetate and diisocyanate while stirring; after the temperature is stable, heating up to 70 DEG C until the measured NCO value is 4-6%; cooling and adding polyether amine, diethylenetriamine, acetone, isopropyl alcohol and alcohol; heating up to 70-75 DEG C; and maintaining even backflow until ketone is completely removed, and taking the product as the component A. The bi-component high-temperature resistant alcohol-soluble ink binder can be applied to ink printing, is wide in printing application scope and good in ink attachment fastness, and can resist high temperature.

Owner:广东国望精细化学品有限公司 +2

Organic boron crosslinking agent and guar gum fracturing fluid

InactiveCN109280547AReduce dosageFacilitate cross-linkingDrilling compositionCross-linkDiethylenetriamine

The invention discloses an organic boron crosslinking agent prepared by reacting boric acid with an organic polyamine compound in the absence of water, wherein the organic polyamine compound is selected from diethylenetriamine, triethylenetetramine, 1,4,7,10,13-pentaazatridecane, polyethylene-polyamines or polyethyleneimine. The invention also discloses a guar gum fracturing fluid, which includes,by weight, the following components:0.2%-0.6% of hydroxypropyl guar gum, 0.2%-0.6% of the organic boron crosslinking agent described in claim 1, 0.01%-0.2% of a pH regulating agent, 0-0.5% of a temperature stabilizer, 0.2%-2% of other additives, with the balance being water. The organic boron crosslinking agent of the invention has a large molecular volume and a plurality of cross-linking pointsformed with a low-concentration guar gum aqueous solution, and so, cross-linking properties and temperature resistance performance of a gelled fracturing fluid are improved, the using amount of the cross-linking agent is reduced, and the cost of a fracturing fluid system is reduced. The guar gum fracturing fluid of the invention has good cross-linking properties and good temperature resistance performance, the concentration of the hydroxypropyl guar gum can be adjusted according to the reservoir temperature, and the maximum usage temperature is 150 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

Semi-enclosed organic amine curing agent and application thereof to anti-corrosive coating

ActiveCN102153729AExtend the usable timeGood effectAnti-corrosive paintsEpoxy resin coatingsCross-linkKetone

The invention discloses a semi-enclosed organic amine curing agent, which is characterized by being obtained by mixing and reacting the following substances in percentage by weight: 15-40 percent of epoxy resin, 5-12 percent of amine, 15-35 percent of ketone and 20-35 percent of solvent, wherein the epoxy resin is bisphenol A epoxy resin or bisphenol F epoxy resin; the amine is diethylenetriamineor triethylene tetramine; the ketone is methyl isobutyl ketone or ethyl methyl ketone; and the solvent is toluene or xylene or a mixture of toluene and xylene in any ratio or normal butanol or isobutyl alcohol or a mixture of normal butanol and isobutyl alcohol in any ratio. Semi-enclosed organic amine obtained by multi-step synthesis is cross-linked with epoxy resin and naturally dried into a film, the cross-linked product is de-capsulated into primary amine for further curing with moisture in the air or moisture on the surface of a substrate, and the curing agent is partially enclosed, so that the service life of reactive double-component paint can be greatly prolonged after mixing; and epoxy resin is introduced into the curing agent to form a multi-aromatic ring anti-corrosive prepolymer, so that the corrosion resistance of a final film forming substance is further enhanced.

Owner:CHONGQING SANXIA PAINTS CO LTD

Bilberry extract and preparation method thereof

InactiveCN105287690ASimple and fast operationSuitable for industrial productionOrganic active ingredientsFood preparationLingonberry extractDivinylbenzene

The invention relates to a plant extract, in particular to a bilberry extract and a method for preparing the extract. The content of the bilberry extract is 55%-95%, and the bilberry extract is consistent to finger-print specified in European Pharmacopoeia. The invention also relates to the method for preparing the extract. The method comprises the following steps of extracting the bilberry extract by using macroporous adsorption resin; and concentrating and performing spraying drying on collected extracting solution. According to the method, rate of charge of divinylbenzene to esters monomers of the macroporous adsorption resin used in the method is 19:1-7:3, and a desorption agent used in a desorption process is ethanol or an acid aqueous solution of methyl alcohol or acetone.

Owner:TIANJIN NANKAI SHARE PHARMA SCI & TECH

High-performance waterborne epoxy anticorrosive coating

InactiveCN111876052AIncrease the degree of cross-linkingImprove toughnessAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention provides high-performance water-based epoxy anticorrosive coating. The coating comprises a component A and a component B. The component A is prepared from the following components in parts by weight: 60-70 parts of waterborne epoxy resin emulsion, 5-8.5 parts of styrene-acrylic emulsion, 2-3.5 parts of a zinc oxide / graphene oxide composite material, 0.5-1.2 parts of cerium-doped nanotitanium dioxide, 1-2 parts of nano attapulgite, 3-5 parts of organic bentonite, 0.2-3 part of pigment, 0.3-0.5 part of a silane coupling agent, 2-3 parts of n-butyl alcohol, 0.3-0.6 part of a dispersing agent, 0.3-0.5 part of a defoamer, 0.2-0.4 part of a leveling agent and 18-25 part of deionized water. The component B is prepared from the following components in parts by weight: 30-35 parts ofpolyether amine, 3-5 parts of diethylenetriamine, 25-32 parts of wet sericite powder and 8-12 parts of talcum powder. The anticorrosive coating is environmentally friendly, all the raw materials arematched with one another, and the prepared coating is good in anticorrosive effect, excellent in mechanical property and high in adhesive force.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

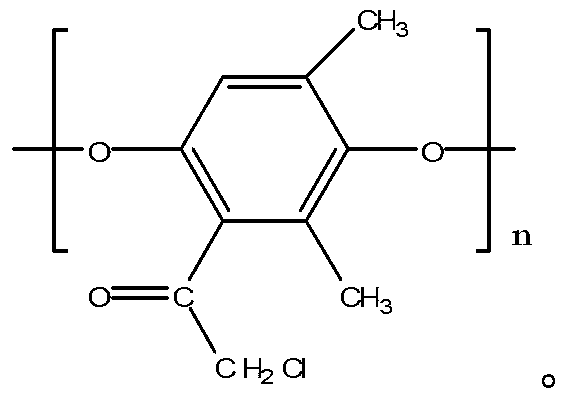

Homogeneous anion-exchange membrane and preparation method thereof

ActiveCN103304830AHigh strengthHomogeneous performance is stableSemi-permeable membranesAnion exchangersBenzoyl peroxideDivinylbenzene

The invention discloses a homogeneous anion-exchange membrane and a preparation method thereof. The preparation method is characterized by comprising the following steps: performing a reaction to obtain a uniform membrane liquid by taking chloromethylated vinyl benzene, vinyl benzene or / and alkyl vinyl benzene as a monomer, divinylbenzene as a crosslinking agent, benzoyl peroxide or azodiisobutyronitrile as an initiator, and quaternized bromomethylated poly(1, 4-dimethyl-2, 6-phenylene oxide) or quaternized chloracetylated poly(1, 4-dimethyl-2, 6-phenylene oxide) as a high molecular enhancer; carrying out a reaction to obtain a uniform membrane liquid and drying the membrane to obtain the anion-exchange membrane. The anion-exchange membrane is high in exchange capacity, good in electrochemical property, uniform in structure and good in heat resistance. As a previous functionalized reaction process is adopted without post-treatment steps, the membrane liquid is uniform and easy to coat, so that the membrane-forming property is good. The anion-exchange membrane obtained is high in mechanical strength, and the ion exchange radicals are uniformly distributed. Products in different structural forms and functions can be obtained by adjusting the content of polymers, types of solvents, quaterisation temperature and time and degree of crosslinking and changing the types of supporters.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

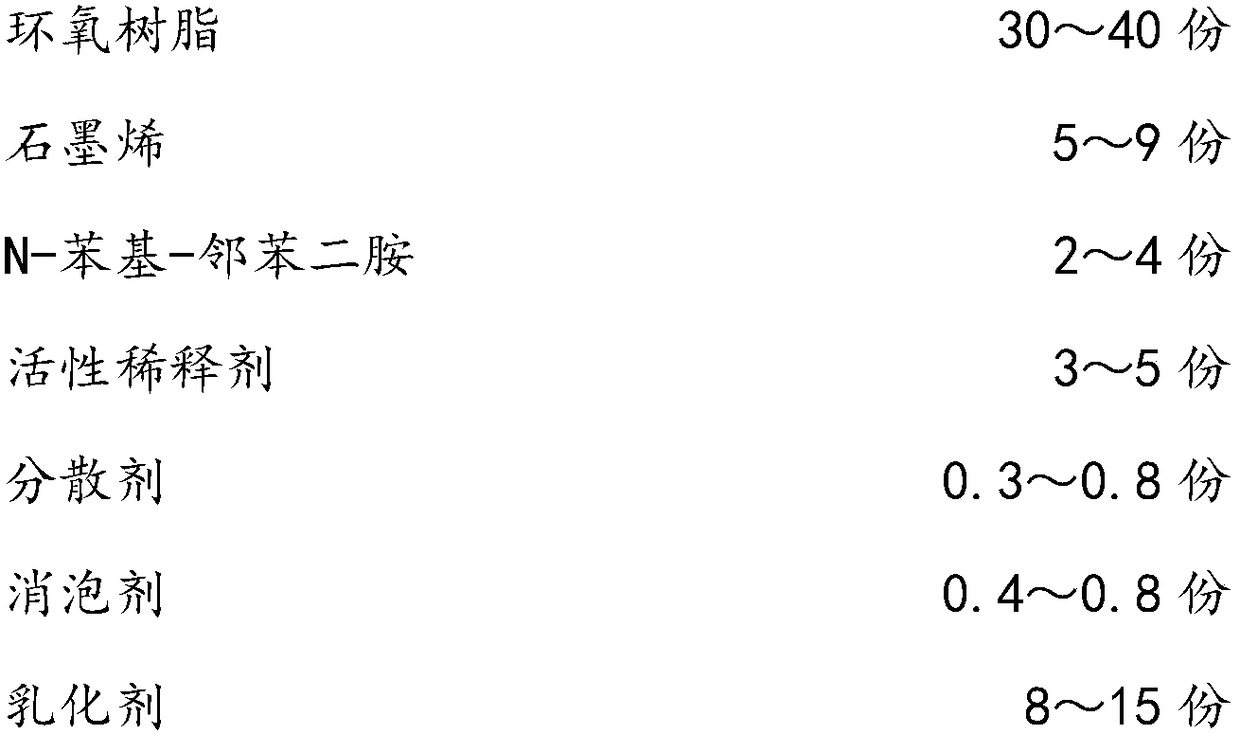

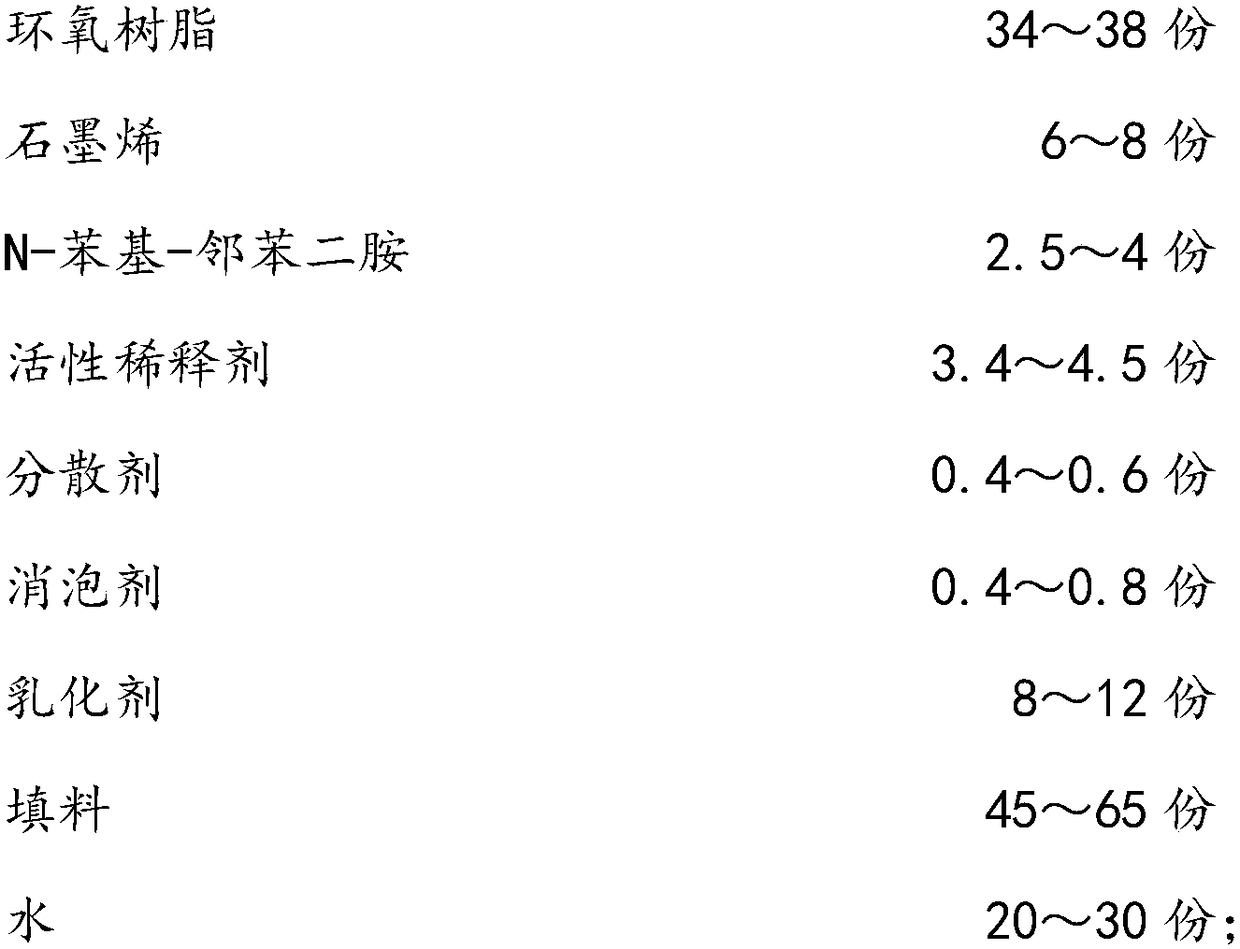

Anti-static graphene floor paint and preparation method thereof

InactiveCN108300161ASolving the Spontaneous Reunion ProblemAvoid loss of electrical conductivityEpoxy resin coatingsElectrically-conductive paintsDiethylenetriamineStatic performance

The invention provides anti-static graphene floor paint and a preparation method thereof. The anti-static graphene floor paint contains a component A and a component B, wherein the component A is prepared from constituents by weight as follows: 30-40 parts of epoxy resin, 2-5 parts of graphene, 2-4 parts of N-phenyl-o-phenylenediamine, 3-5 parts of a reactive diluent, 0.3-0.8 parts of a dispersingagent, 0.4-0.8 parts of a defoaming agent, 8-15 parts of an emulsifier, 40-70 parts of filler and 15-30 parts of water; the component B is prepared from constituents by weight as follows: 8-11 partsof pyromellitic dianhydride, 8-12 parts of amino modified graphene and 6-9 parts of an acrylonitrile-diethylenetriamine compound; a weight ratio of the component A to the component B is 5.5-7:1. The invention further provides the preparation method of the anti-static graphene floor paint. According to the prepared anti-static graphene floor paint, the problem of conductivity reduction due to bedding void caused by graphene layering is solved, and anti-static performance of the floor paint is greatly enhanced.

Owner:厦门中凯新材石墨烯科技有限公司

Rust-proof metal coating and preparation method thereof

ActiveCN104212329AImprove rust resistanceGood foaming performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterPhosphoric Acid Esters

The invention discloses a rust-proof metal coating and a preparation method thereof. The rust-proof metal coating comprises, by weight, 20-40 parts of ammonium lauryl sulfate, 10-60 parts of ribonucleoside triphosphote, 35-70 parts of titanium dioxide, 25-50 parts of polyethylene polyamine, 5-30 parts of sebacic acid, 15-50 parts of isopropanolamine, 40-80 parts of sulfitation, 25-35 parts of octadecanol phosphate sodium salt, 10-40 parts of polyester type carbamic acid ester, 30-90 parts of divinyl tetramine, 30-60 parts of tertiary butyl anthraquinone and 20-70 parts of surface active agent. The preparation method comprises the steps of evenly mixing the ammonium lauryl sulfate, the ribonucleoside triphosphote, the titanium dioxide and the polyethylene polyamine, then adding the octadecanol phosphate sodium salt and the polyester type carbamic acid ester and heating the materials to be at the temperature ranging from 80 DEG C to 90 DEG C so as to perform reaction for 20-30 min; adding the sebacic acid, the isopropanolamine, the sulfitation, the divinyl tetramine, the tertiary butyl anthraquinone and the surface active agent into water at the temperature ranging from 30 DEG C to 40 DEG C to be dissolved, then adding the mixture to perform even stirring. The rust-proof metal coating is good in rust-proof performance, foaming performance and overall performance and wide in application range.

Owner:FUJIAN HONGGUAN ROADS & BRIDGE ANTI CORROSIVE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com