Organic boron crosslinking agent and guar gum fracturing fluid

A technology of organic boron and cross-linking agent, which is applied in the field of organic boron cross-linking agent and guar gum fracturing fluid containing the cross-linking agent, can solve the problem of weak intermolecular force of guar gum, poor hanging performance, and intermolecular cross-linking. Low linking degree and other problems, to achieve good cross-linking performance and temperature resistance, improve cross-linking performance and temperature resistance, and reduce the amount of cross-linking agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 prepares organoboron crosslinking agent

[0041] Add 31g of boric acid and 120g of ethylene glycol into a four-necked flask equipped with a condenser / water separator, a stirring paddle, a dropping funnel, and a thermometer, and heat up to 65°C under stirring. After all the materials are dissolved, add 37g of n-butyl Alcohol, heated to 115°C with stirring, reacted for 2 hours, until the amount of released water did not change, and the amount of water was about 25g; then added 19g of tetraethylenepentamine dropwise to the four-necked flask, raised the temperature to 130°C, reacted for 2 hours, until the released water The amount of n-butanol does not change anymore, the amount of n-butanol is about 35g, and finally cooled to room temperature to obtain the product.

Embodiment 2

[0042] Example 2 Preparation of fracturing fluid base fluid

[0043] Add 493g of water into the mixer, add 1.50g of instant hydroxypropyl guar gum SRG-1 under stirring, after dissolving for 3 minutes, add 0.5g of sodium gluconate, 2.50g of anti-swelling agent FP-1, 1.5g of drainage aid Agent ME-2, 0.5g sodium carbonate, 0.5g fungicide SK-1 and 0.5g anti-emulsifier SF-1, stirred and dissolved for 2min, let stand for 1h, and prepared fracturing fluid base fluid with guar gum concentration of 0.30%. Fracturing fluid base fluid apparent viscosity 21mPa s (170s -1 ), the pH value is 10.5.

Embodiment 3

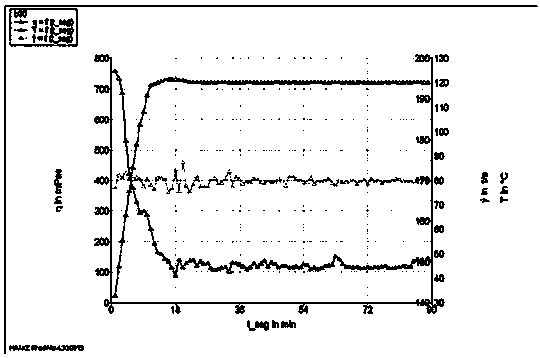

[0044] Example 3 Fracturing Fluid Crosslinking Performance and Temperature and Shear Resistance

[0045] Take 100 mL of the fracturing fluid base fluid prepared in Example 2, add 0.35 g of the organoboron cross-linking agent prepared in Example 1, and obtain hydroxypropyl guar gum boron jelly fracturing fluid, and the cross-linking time is 1 min. The cross-linking jelly can be Hanging glass rods. Using the fracturing fluid temperature and shear resistance test method specified in SY / T 5107-2005 "Water-based Fracturing Fluid Performance Evaluation Method", the fracturing fluid resistance at 120°C was tested with a HAAKE MARS III high temperature rheometer. temperature and shear properties, results such as figure 1 stated, 120℃, 170s -1 The apparent viscosity of the system is 142mPa·s under shear conditions for 90min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com