Electrophoresis particle of polymer dye (pigment) for electronic ink and preparation method thereof

A technology of electrophoretic particles and electronic ink, which is applied in the direction of organic dyes, inks, applications, etc., can solve the problems of poor movement effect and uneven shape of organic pigment particles, and achieve the advantages of overcoming uneven shape, bright colors, and easy availability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

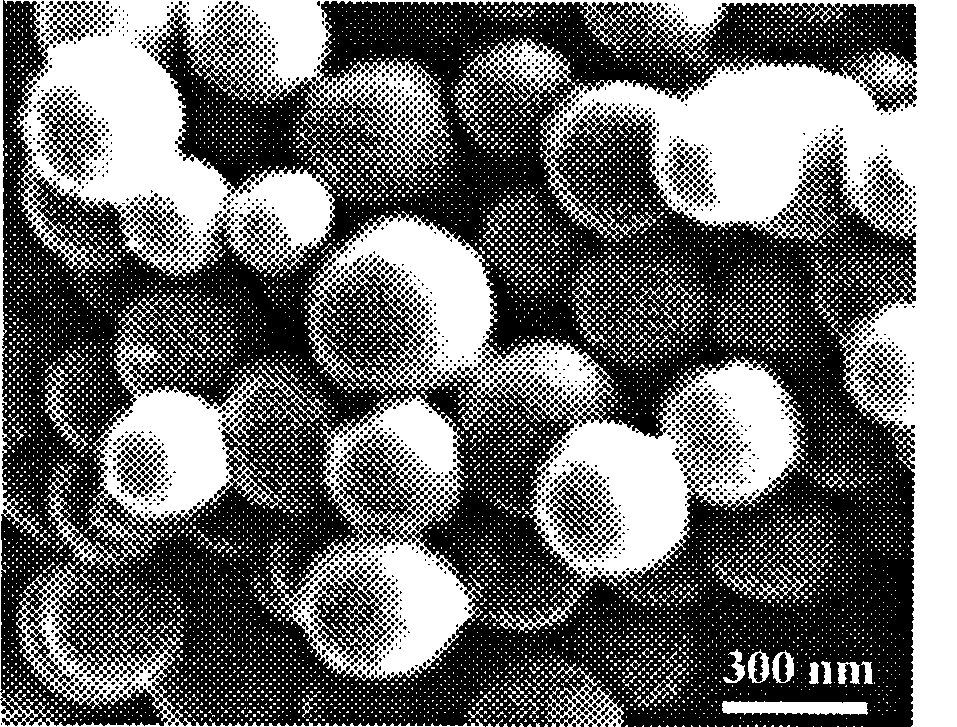

Image

Examples

example 1

[0017] Dissolve 1.0g of Disperse Orange GR (C.I.Disperse Orange 3) in 50mL of dichloromethane, add 3g of acryloyl chloride to the dichloromethane solution of the above dye at a rate of 30 drops / min under the reaction condition of 0°C In the closed flask, stir at 500r / min, after the dropwise addition of acryloyl chloride, raise the temperature to 20°C, and continue stirring for 0.5 hours to prepare a dye solution with polymerizable functional groups;

[0018] The solution prepared in the above steps was washed twice with 0.5M NaOH and HCl solution respectively, and then washed with water for 3 times, and the dichloromethane solvent was evaporated to obtain 0.8 g of the corresponding pigment powder with polymerizable functional groups;

[0019] Take 1g of the pigment prepared in the above steps, dissolve it in 100mL of ethanol, add 5g of styrene, 0.5g of divinylbenzene, and 0.01g of initiator AIBN under the conditions of 80°C and 200r / min, react for 7h under the protection of nit...

example 2

[0021] Dissolve 1.0g of Disperse Red RLZ (C.I.Disperse Red 4) in 50mL of dichloromethane, add 1g of acryloyl chloride to the dichloromethane solution of the above dye at a rate of 40 drops / min under the reaction condition of 0°C In the closed flask, stir at 650r / min, after the dropwise addition of acryloyl chloride, raise the temperature to 10°C, and continue stirring for 1.5 hours to prepare a dye solution with polymerizable functional groups;

[0022] The solution prepared in the above steps was washed twice with 0.5M NaOH and HCl solution respectively, and then washed with water for 3 times, and the dichloromethane solvent was evaporated to obtain 0.9 g of the corresponding pigment powder with polymerizable functional groups;

[0023] Take 1g of the pigment prepared in the above steps, dissolve it in 100mL of ethanol, add 1g of styrene, 0.5g of divinylbenzene, and 0.05g of initiator AIBN under the conditions of 70°C and 300r / min, react for 9h under nitrogen protection, and c...

example 3

[0025] Dissolve 1.0g of disperse violet (C.I.Disperse Red 11) in 50mL of dichloromethane, add 3g of acryloyl chloride to the airtight container of the above-mentioned dye in dichloromethane at a rate of 50 drops / min under the reaction condition of 0°C. In the flask, stir at 600r / min, after the dropwise addition of acryloyl chloride, raise the temperature to 15°C, and continue to stir for 2 hours to prepare a dye solution with polymerizable functional groups;

[0026] The solution prepared in the above steps was washed twice with 0.5M NaOH and HCl solution respectively, and then washed with water for 3 times, and the dichloromethane solvent was evaporated to obtain 0.9 g of the corresponding pigment powder with polymerizable functional groups;

[0027] Take 1g of the pigment prepared in the above steps, dissolve it in 100mL of ethanol, add 3g of styrene, 0.5g of divinylbenzene, and 0.02g of initiator AIBN under the conditions of 65oC and 200r / min, react for 7h under the protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com