Method for chemical modification of surface of graphene oxide and application

A graphene surface, chemical modification technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as poor dispersion and weak interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

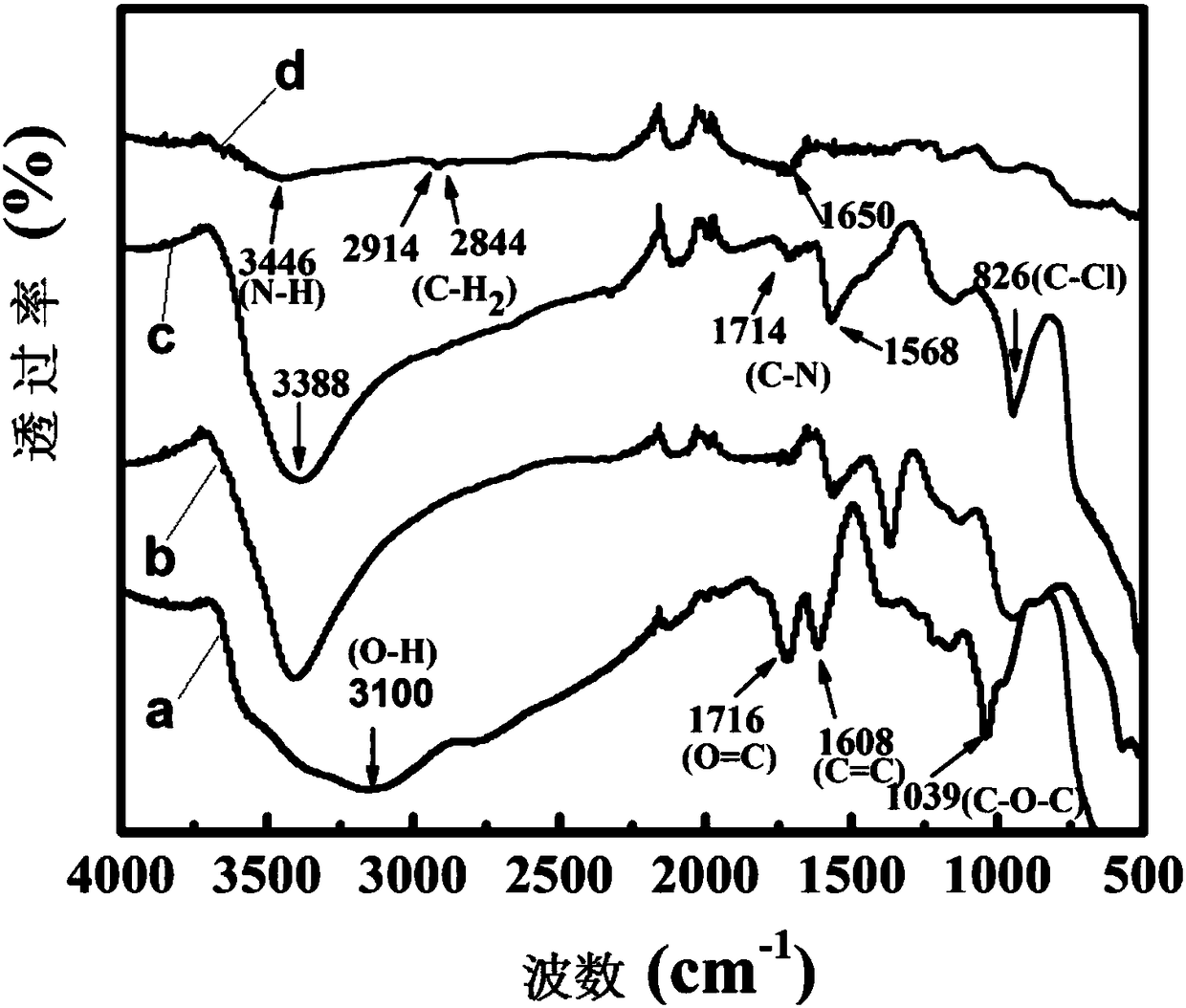

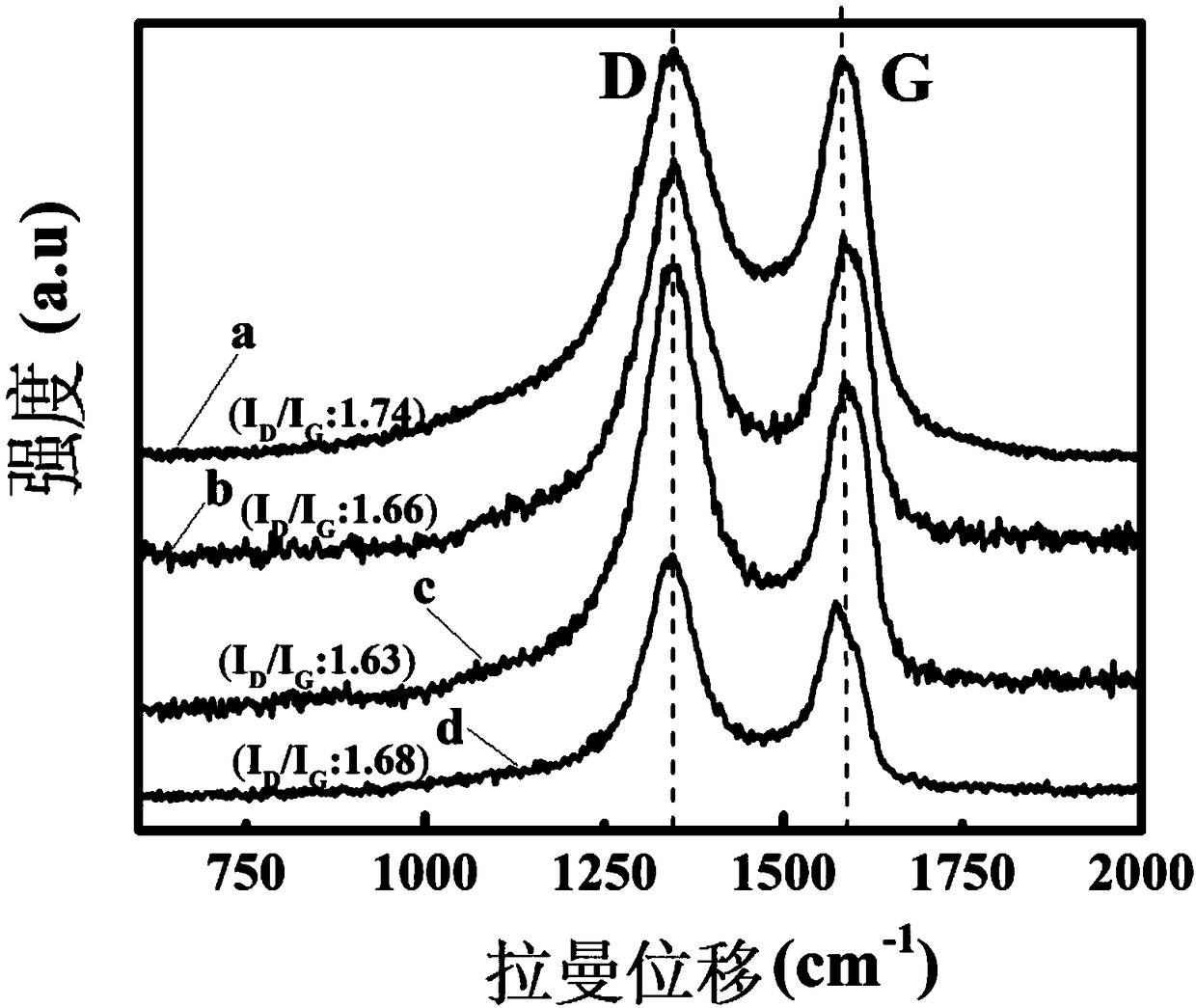

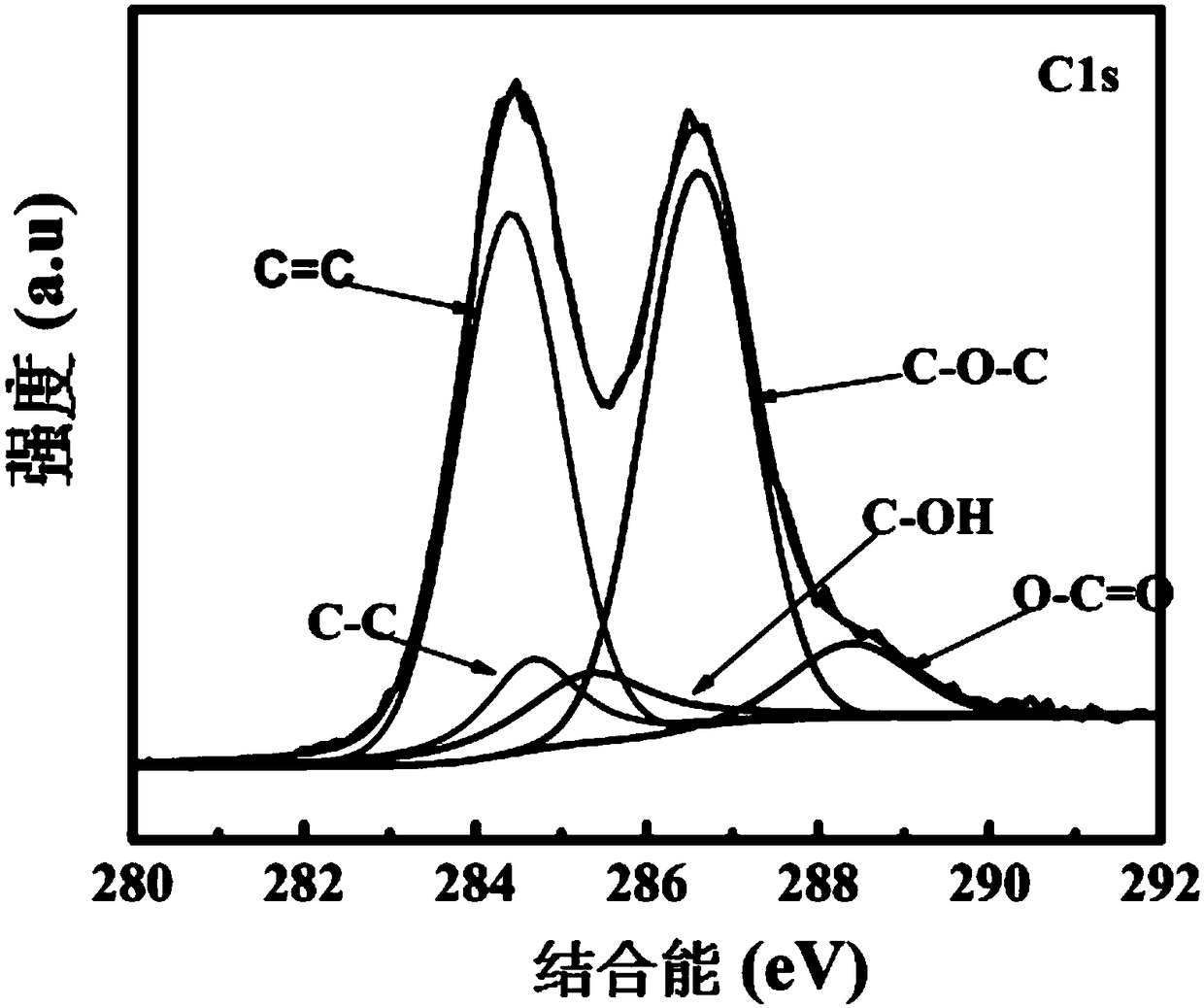

[0076] Specific embodiment one: the method for chemically modifying the surface of graphene oxide in this embodiment is carried out according to the following steps;

[0077] Step 1, preparing graphene oxide:

[0078] ①. Add graphite, sodium nitrate and concentrated sulfuric acid into a three-necked flask, place the three-necked flask in an ice-water bath at 0°C-5°C and stir for 30min-40min at a stirring speed of 300r / min-400r / min. Obtain reaction solution I;

[0079] The massfraction of the concentrated sulfuric acid described in step 1. is 96%~98%;

[0080] The quality of the graphite described in step 1. and the volume ratio of the concentrated sulfuric acid are (6g~8g):(360mL~500mL);

[0081] Step 1. The quality of sodium nitrate described in 1. and the volume ratio of the concentrated sulfuric acid are (2g~4g):(360mL~500mL);

[0082] ②. Add potassium permanganate to the reaction solution I, then place the three-neck flask in an ice-water bath at 0°C to 5°C and stir for...

specific Embodiment approach 2

[0119] Embodiment 2: This embodiment is different from Embodiment 1 in that: freeze-dry at a temperature of -10°C to -5°C for 24h to 36h. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0120] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying process described in Step 3 ③ is: drying in a vacuum oven at 80°C to 90°C for 4h to 6h. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com