Method for preparing large-area semitransparent perovskite thin film by using scraper coating method and application of large-area semitransparent perovskite thin film

A blade coating, perovskite technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of limited large-area preparation, complex process, high energy consumption, etc., and achieve excellent thermodynamic stability, Simple process, effective absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

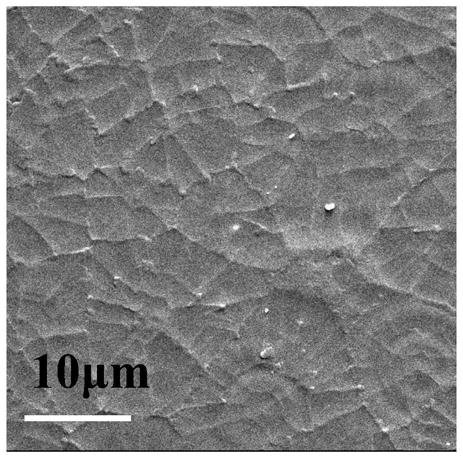

[0040] A method for preparing a large-area, translucent perovskite film using a doctor blade coating method is provided, and the specific steps are as follows:

[0041] 1) Preparation of perovskite precursor solution

[0042] Weigh 256.9mg PbBr 2 , 87.5mg FABr and dissolve it in 800μL DMF and DMSO mixed solution (DMF and DMSO volume ratio is 4:1); continue to dropwise add 40ul of lecithin DMF and DMSO mixed solution, place on a magnetic stirrer and stir Stand by for 2 hours to obtain a perovskite precursor solution of about 0.7M, wherein the concentration of lecithin in the perovskite precursor solution is 0.2mg / mL.

[0043] 2) Coating of perovskite precursor solution

[0044] 5×2.5cm 2 Put the FTO glass substrate into the PLASMA plasma cleaning machine to clean for 5 minutes to enhance the wettability of the FTO glass substrate to the perovskite precursor solution. Set the substrate of the blade coater to a preheating temperature of 150°C, and place the FTO glass substrat...

Embodiment 2

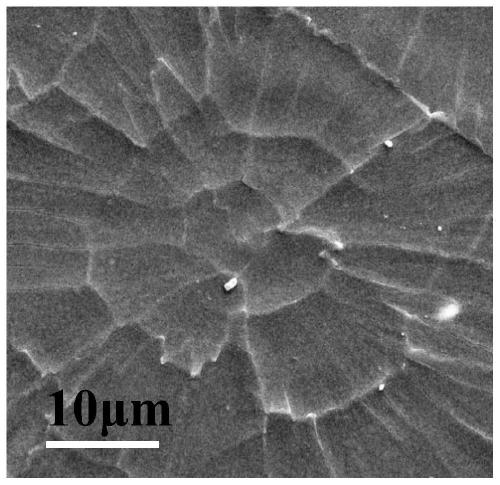

[0048] A method for preparing a large-area, translucent perovskite film using a doctor blade coating method is provided, and the specific steps are as follows:

[0049] 1) Preparation of perovskite precursor solution

[0050] Weigh 256.9mg PbBr 2 , 87.5mg FABr and dissolve it in the mixed solution of 800μL DMF and DMSO (the volume ratio of DMF and DMSO is 4:1), continue to add dropwise the mixed solution of DMF and DMSO of 40ul cetyltrimethylammonium bromide Place it on a magnetic stirrer and stir for 2 hours to obtain a 0.7 M perovskite precursor solution, wherein the concentration of cetyltrimethylammonium bromide in the perovskite precursor solution is 0.2 mg / mL.

[0051] 2) Coating of perovskite precursor solution

[0052] 5×2.5cm 2 Put the FTO glass substrate into the PLASMA plasma cleaning machine to clean for 5 minutes to enhance the wettability of the FTO glass substrate to the perovskite precursor solution. Set the substrate of the blade coater to a preheating tem...

Embodiment 3

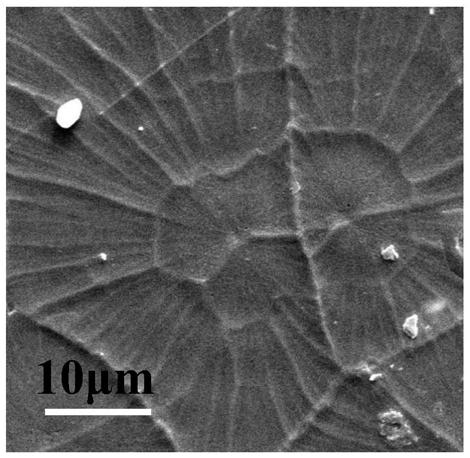

[0058] A method for preparing a large-area, translucent perovskite film using a doctor blade coating method is provided, and the specific steps are as follows:

[0059] 1) Preparation of perovskite precursor solution

[0060] Weigh 256.9mg PbBr 2 , 87.5mg FABr and dissolve it in 800 μL of DMF and DMSO mixed solution (DMF and DMSO volume ratio is 4:1), continue to drop 40ul of DMF and DMSO mixed solution of sodium dodecylsulfonate and place it under magnetic force Stir on the stirrer for 2 hours and wait for use to obtain a 0.7M perovskite precursor solution, wherein the concentration of sodium dodecylsulfonate in the perovskite precursor solution is 0.2 mg / mL.

[0061] 2) Coating of perovskite precursor solution

[0062] 5×2.5cm 2 Put the FTO glass substrate into the PLASMA plasma cleaning machine to clean for 5 minutes to enhance the wettability of the FTO glass substrate to the perovskite precursor solution. Set the substrate of the blade coater to a preheating temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com