Electron collector material and preparation method of electron collector

An electron collection and collector technology, which is applied to the collector of the transit time type electron tube, the manufacture of the electrode system, the manufacture of the discharge tube/lamp, etc., which can solve the difficulty of maintaining the vacuum of the HPM system and the small secondary electron emission coefficient. , vacuum system carbon pollution and other problems, to achieve the effect of high melting point, low atomic number, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

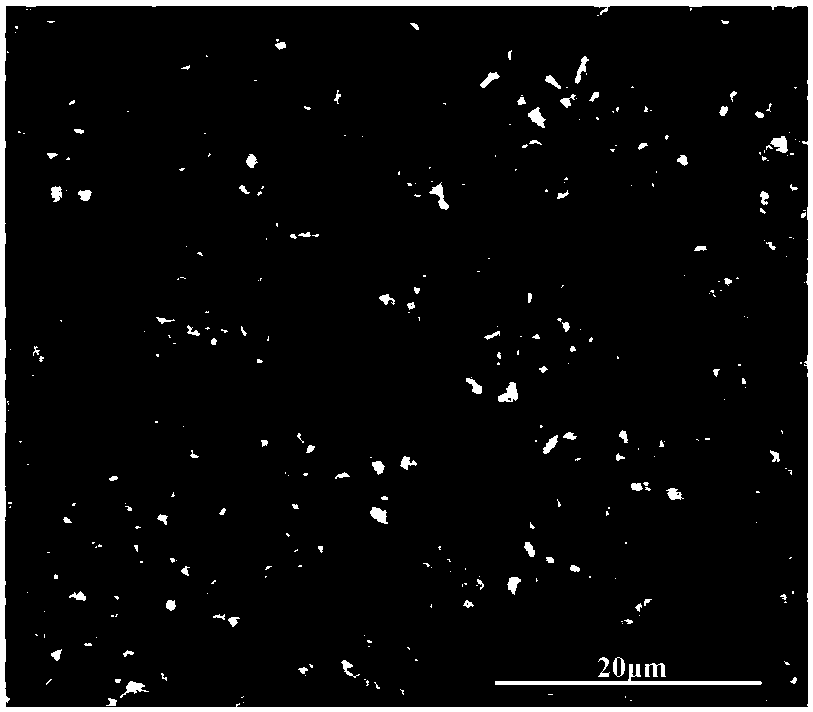

[0040] An electron collector material of the present invention includes a graphite matrix, and also includes TiC that penetrates into the interior of the graphite matrix relative to the surface of the graphite matrix, the TiC is formed by the in-situ reaction of elemental Ti and carbon in the graphite matrix, and the TiC is filled on the surface of the graphite matrix and in the internal pores.

[0041] In this embodiment, the TiC has a composition gradient from the surface of the graphite matrix to the interior of the graphite matrix, with a depth of about 120 μm.

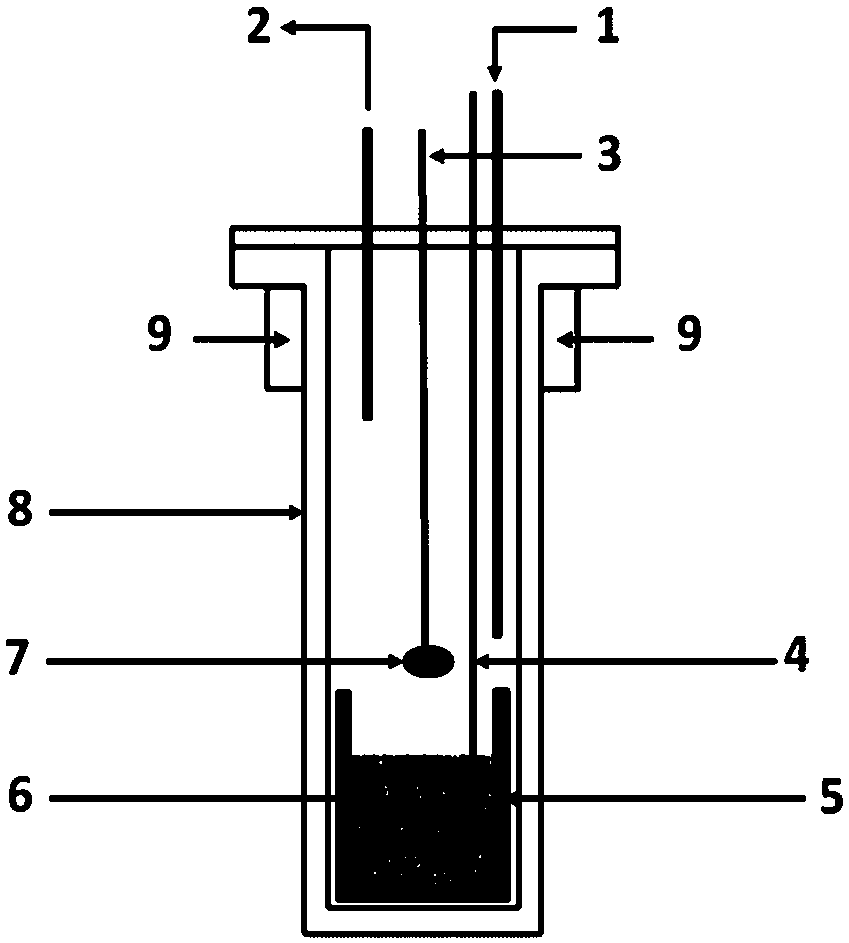

[0042] A preparation method of electron collector of the present invention, comprises the following steps:

[0043] (1) Preparation of graphite collector body:

[0044] Using graphite as a raw material, according to the size requirements of the collector, the graphite block is processed into a flat graphite collector body 7 by conventional machining methods;

[0045] (2) Prepare collector preform:

[0046] (2.1...

Embodiment 2

[0054] An electron collector material of the present invention comprises a graphite matrix, TiC that penetrates into the interior of the graphite matrix relative to the surface of the graphite matrix and a TiC coating that covers the surface of the graphite matrix, and the TiC that penetrates into the interior of the graphite matrix is elemental Ti and carbon in the graphite matrix Formed by in-situ reaction, the TiC coating is formed by the in-situ reaction of elemental Ti and carbon on the surface of the graphite substrate. The thickness of the TiC coating covering the surface of the graphite substrate is 10 μm to 15 μm, and there is a gradient of TiC infiltrating from the surface of the graphite substrate into the interior of the graphite substrate, with a depth of about 400 μ to 430 μm, and is filled in the pores inside the graphite substrate.

[0055] A preparation method of electron collector of the present invention, comprises the following steps:

[0056] (1) Prepara...

Embodiment 3

[0066] An electron collector material of the present invention comprises a graphite matrix, TiC that penetrates into the interior of the graphite matrix relative to the surface of the graphite matrix and a TiC coating that covers the surface of the graphite matrix, and the TiC that penetrates into the interior of the graphite matrix is elemental Ti and carbon in the graphite matrix Formed by in-situ reaction, the TiC coating is formed by the in-situ reaction of elemental Ti and carbon on the surface of the graphite substrate. The thickness of the TiC coating covering the surface of the graphite substrate is 28 μm to 30 μm, and the content of TiC infiltrated from the surface of the graphite substrate to the interior of the graphite substrate has a gradient of decreasing content, with a depth of 415 μm to 430 μm, and is filled in the pores on the surface and inside of the graphite substrate.

[0067] A preparation method of electron collector of the present invention, comprises...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com