Casting process of aluminum alloy slab ingot

A casting process and aluminum alloy technology, applied in the field of aluminum alloy slab ingot casting process, can solve the problems of low production capacity, small order quantity, waste of resources, etc., and achieve the effects of reducing production cost, shortening casting time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

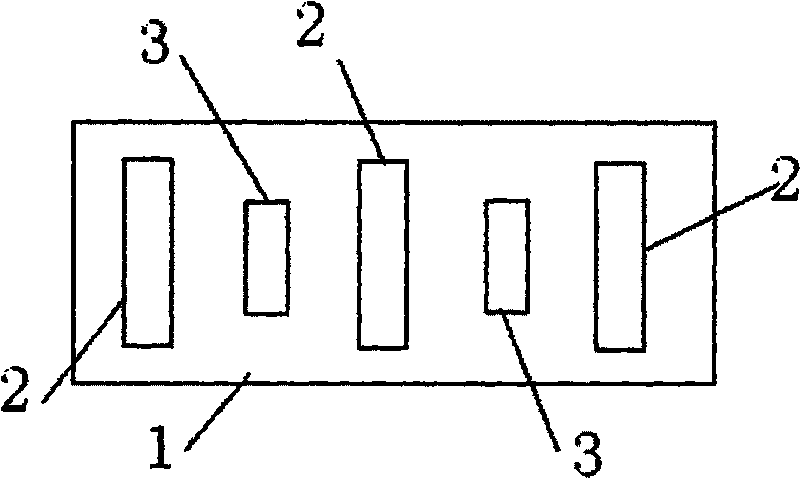

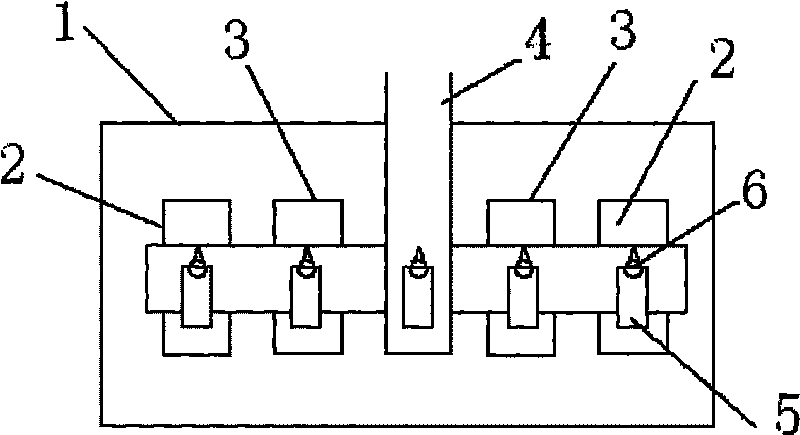

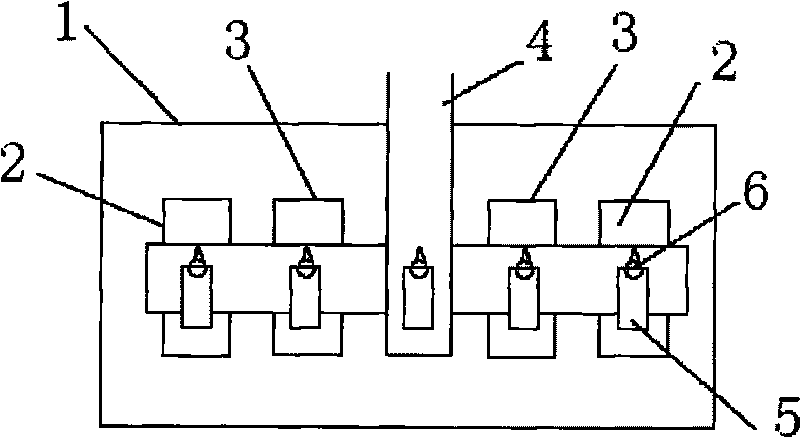

[0031] The aluminum alloy flat ingot casting process of the present embodiment refers to the appended Figure 1-2 , casting 3 aluminum alloy flat ingots with a specification of 560×1310×8400, and 2 aluminum alloy flat ingots with a specification of 620×1150×8200. The specific process is as follows:

[0032] 1. Check devices and instruments

[0033] Check all safety devices and ensure that all instruments are functioning properly;

[0034] Formulate casting process system

[0035] First, compare the casting process parameters of ingots of different specifications cast in the same casting order, namely casting speed, water flow rate, secondary water valve, control pin opening degree, and casting transition section, and find out the same process parameters and different ones by comparison. Process parameters, among them, the casting speed shall be subject to the slowest process of the same casting time, the water flow rate shall be subject to the maximum water flow rate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com