High-strength insulation material pantograph

An insulating material, high-strength technology, used in the field of pantographs, which can solve problems such as blowing bottles, supporting insulator pollution, and flashover breakdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

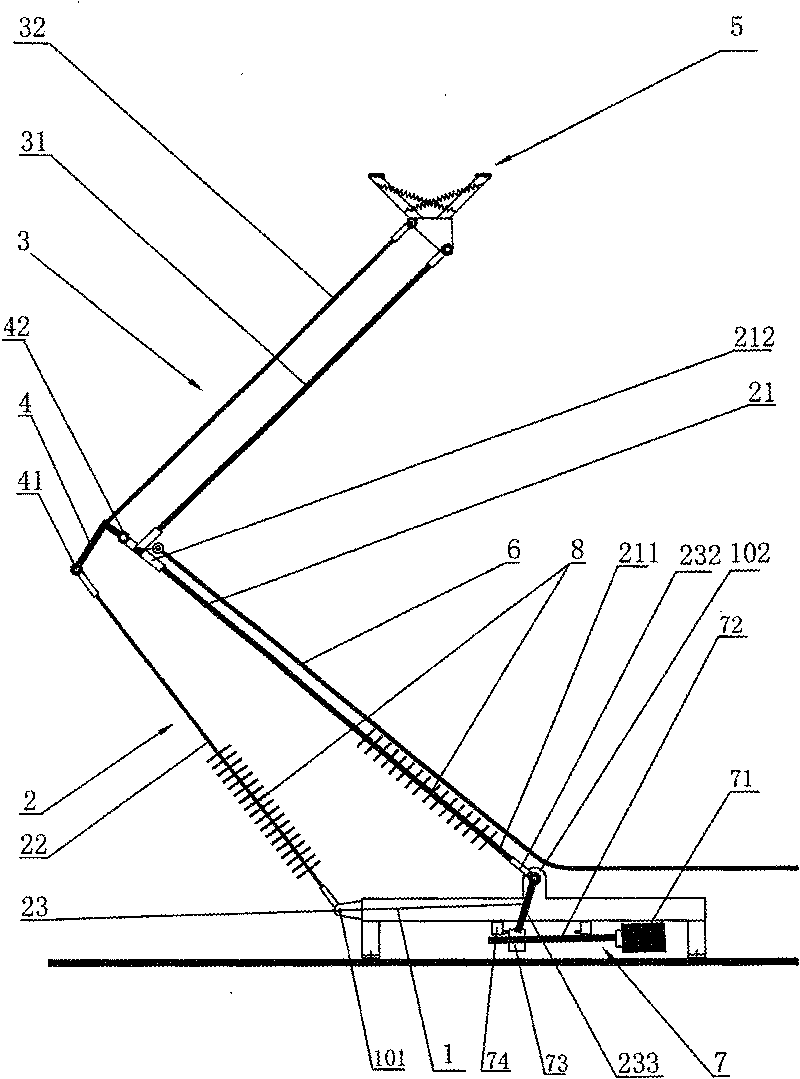

[0033] Such as figure 1 , figure 2 The shown pantograph of high-strength insulating material includes an underframe 1 , a lifting frame 2 , a supporting frame 3 , a hinge seat 4 , a sliding plate mechanism 5 , an insulating cable 6 and a drive system 7 .

[0034] Described chassis 1 (see Figure 9 , Figure 10 ) is made of section steel, the front end is provided with the fourth hinge lug 101, and the top is provided with the fifth hinge lug 102. The underframe 1 is directly fixed to the roof of the locomotive by screws.

[0035] Described lifting frame 2 is made up of lower arm bar 21, push arm 22 and rocking bar seat 23. Described rocker seat 23 (as Figure 7 with Figure 8) is made up of support bar 231, installation boss 232 and rocking arm 233, and the two ends of support bar 231 have installation hole, and the installation boss 232 of support bar 231 middle part also has installation hole, and two rocking arms 233 are located on the support bar, A first hinge lug...

no. 2 approach

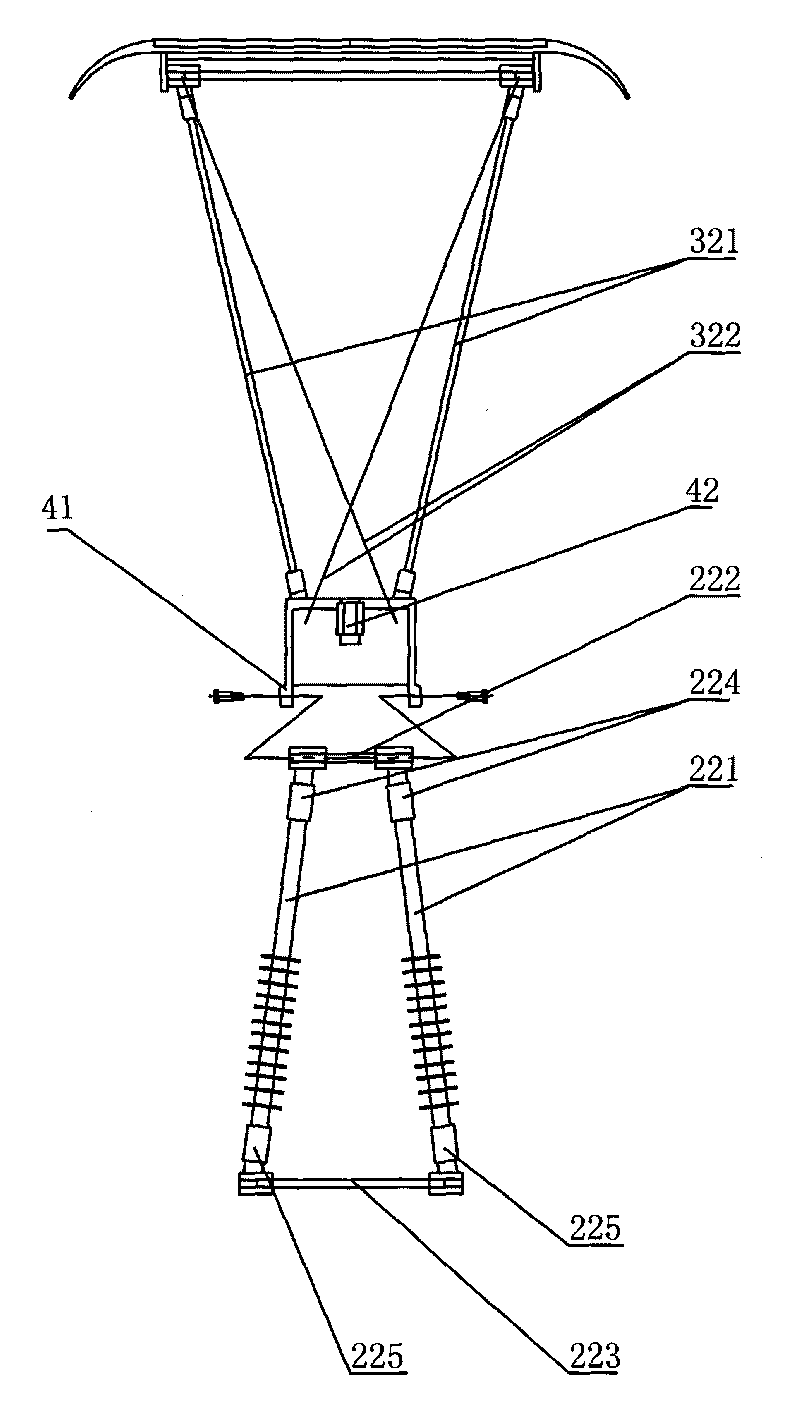

[0047] Such as image 3 , Figure 4 The shown pantograph of high-strength insulating material is composed of an underframe 1, a lifting frame 2, a supporting frame 3, a hinge seat 4, a slide mechanism 5, an insulating cable 6, and a drive system 7.

[0048] Described chassis 1 (see Figure 9 , Figure 10 ) is made of section steel, the front end is provided with the fourth hinge lug 101, and the top is provided with the fifth hinge lug 102. The underframe 1 is directly fixed to the roof of the locomotive by screws.

[0049] Described lifting frame 2 is made up of lower arm bar 21, push arm 22 and rocking bar seat 23. Described rocker seat 23 (as Figure 7 ) is made up of support bar 231, installation boss 232 and rocking arm 233, and the two ends of support bar 231 have installation hole, and the installation boss 232 of support bar 231 middle part also has installation hole, and two rocking arms 233 are located on the support bar, A first hinge lug 2331 is provided on t...

no. 3 approach

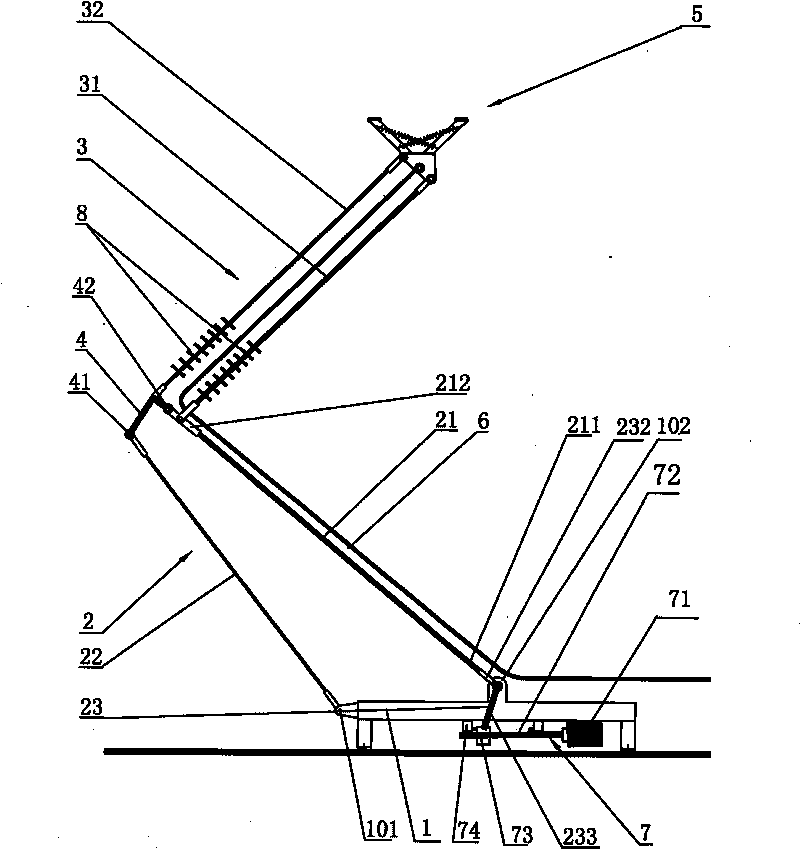

[0061] Such as Figure 5 with Image 6 The shown pantograph of high-strength insulating material is composed of an underframe 1, a lifting frame 2, a supporting frame 3, a hinge seat 4, a slide mechanism 5, an insulating cable 6, and a drive system 7.

[0062] Described chassis 1 (see Figure 9 , Figure 10 ) is made of section steel, the front end is provided with the fourth hinge lug 101, and the top is provided with the fifth hinge lug 102. The underframe 1 is directly fixed to the roof of the locomotive by screws.

[0063] The lifting frame 2 and the supporting frame 3 are made of high-strength insulating materials, such as glass fiber reinforced insulating rods, and the pantograph is insulated from the roof of the locomotive through the lifting frame 2 and the supporting frame 3 .

[0064] Described slide plate mechanism 5 (see Figure 11 ) includes a slide plate 51 and a floating bracket 52, the floating bracket 52 is composed of a spring and a parallelogram mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com