Novel hydraulic type inerter damping device

A shock absorber and hydraulic technology, applied in the direction of shock absorber, liquid shock absorber, spring/shock absorber, etc., can solve the problem of increased damping force, achieve the effect of improving shock absorbing performance and weakening the coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

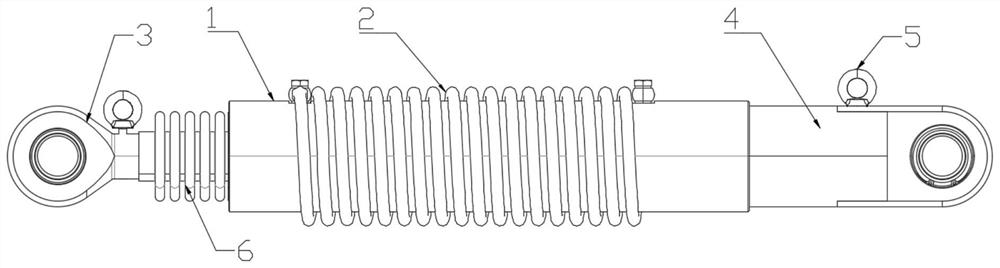

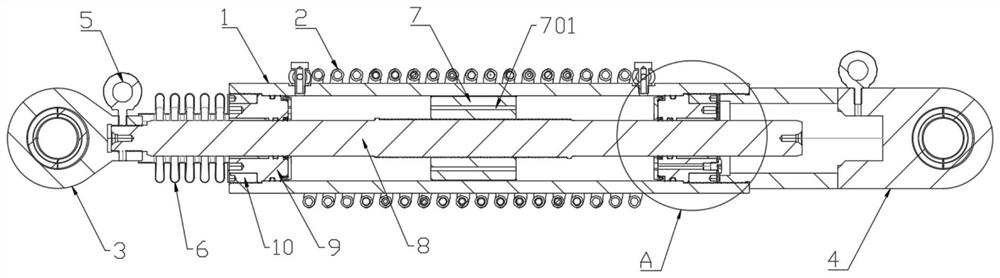

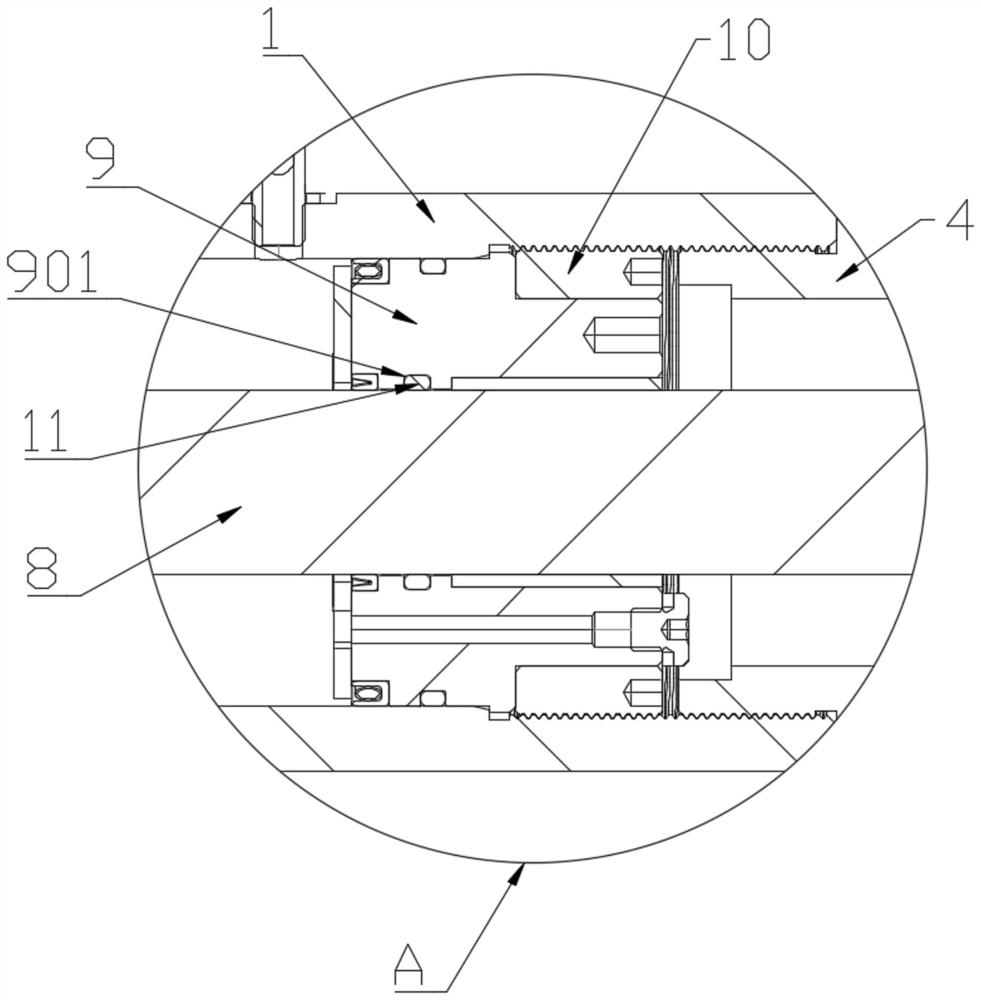

[0025] Such as Figure 1 ~ Figure 4 As shown, a new type of hydraulic inertial shock absorber includes a hydraulic cylinder 1, both ends of the hydraulic cylinder 1 are provided with sealing sleeves 9, and the outer side of the sealing sleeve 9 is equipped with a fastening ring 10, and the fastening ring 10 It is screwed and connected with the inner wall of the hydraulic cylinder 1. The sealing sleeve 9 is fixed in the hydraulic cylinder 1 through the fastening ring 10. The piston rod 8 is inserted into the hydraulic cylinder 1. The piston rod 8 is connected with the hydraulic cylinder 1 through two sealing sleeves 9. The diameter of the two ends of the piston rod 8 is the same as the inner diameter of the sealing sleeve 9, and the inner wall of the sealing sleeve 9 is provided with a sealing groove 901, and a sealing rubber ring 11 is fixedly installed in the sealing groove 901 to prevent leakage. There is a piston 7 in the liquid cylinder 1, the piston 7 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com