Vibration-damping seat

A seat and backrest technology, applied in vehicle seats, seat suspension devices, special positions of vehicles, etc., can solve problems such as motion sickness, poor ventilation of foam blocks, irritability and discomfort, and achieve good applicability and vibration reduction effect. Good, the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

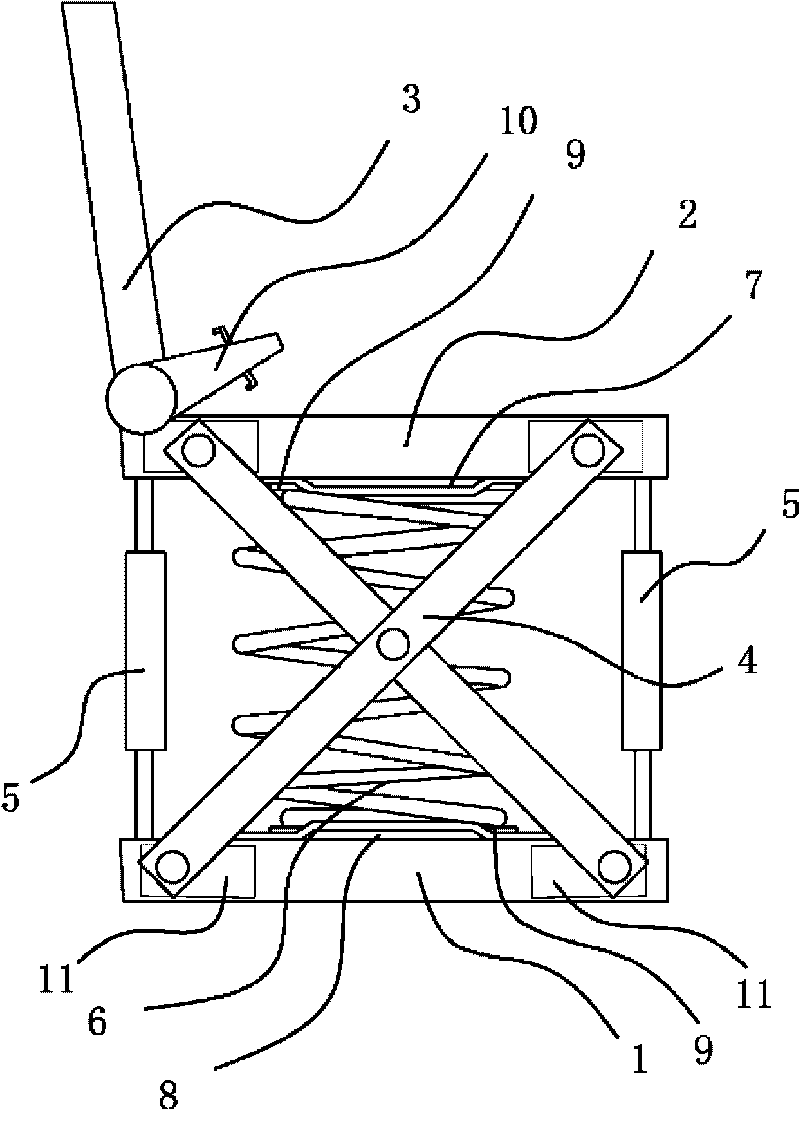

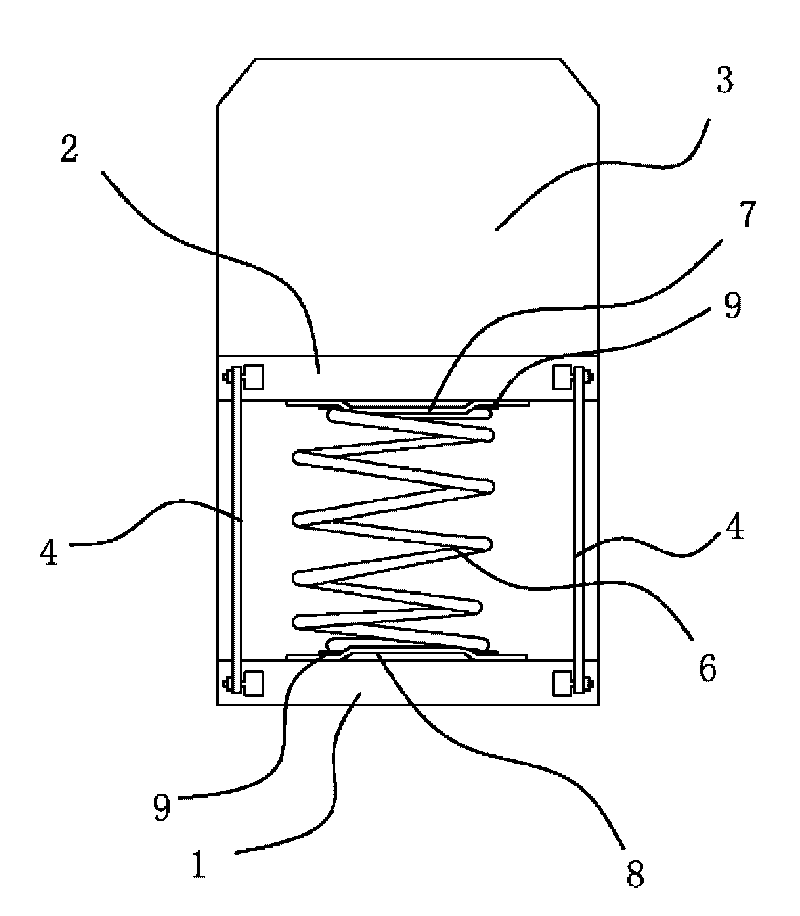

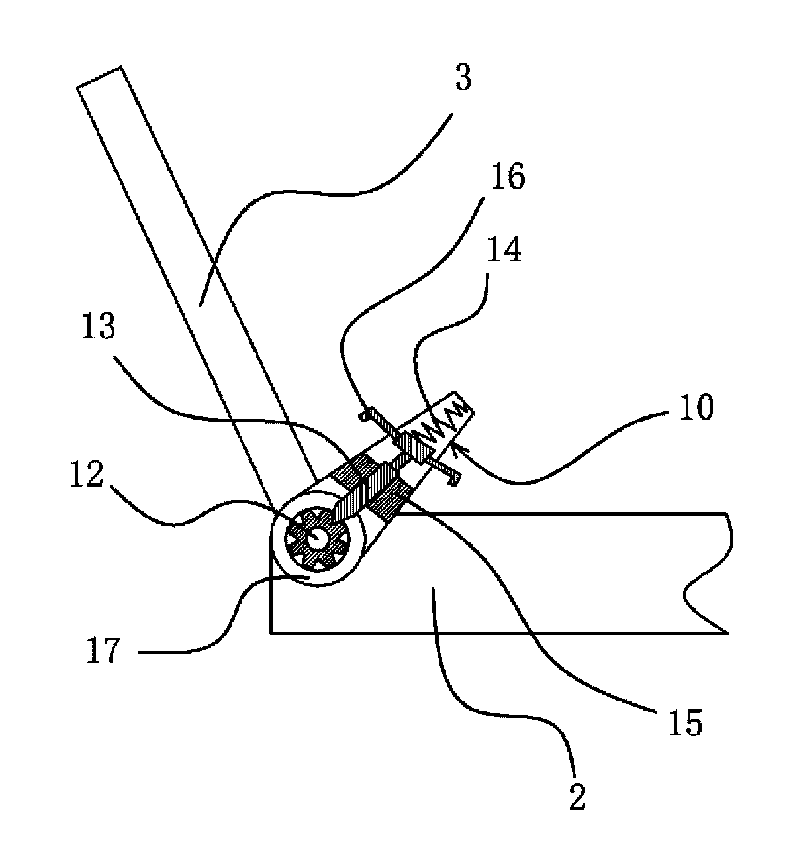

[0022] Such as figure 1 and figure 2 As shown, the damping seat includes a lower support 1, an upper support 2 and a backrest 3 connected to the upper support 2, and a regulator 10 capable of adjusting the elevation angle of the backrest 3 is provided at the joint between the backrest 3 and the upper support 2. As the user's body is different, the required elevation angle of the backrest 3 is also different, and the adjuster 10 can adjust the elevation angle of the backrest 3 according to the actual needs of the user. A spring 6 is arranged between the upper support 2 and the middle part of the lower support 1 , and several dampers 5 are symmetrically distributed on the front and rear sides between the upper support 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com