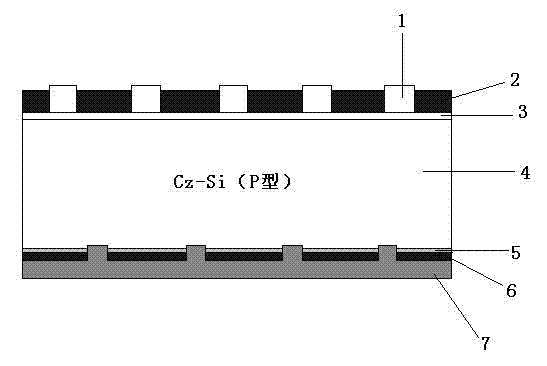

Windowing process of solar crystalline silicon battery

A technology of crystalline silicon battery and window opening technology, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc. Unstable window effect and other problems, to achieve the effect of low thickness uniformity, good applicability, and stable window opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Front-end process: Firstly, monocrystalline silicon wafers are placed in a NaOH solution with a mass concentration of 1.2% at 80°C for 15 minutes to form a pyramidal textured structure on the front and back sides, which are then cleaned with pure water and dried; Phosphorus is diffused on the front side of the chip to form an emitter (prior art), and the diffusion resistance is 70R 方 ; With a concentration of 7% HF solution, the phosphosilicate glass on the surface of the silicon wafer is cleaned and dried; then a layer of nitride is deposited on the front of the silicon wafer by PECVD (enhanced plasma vapor deposition method, prior art) Silicon anti-reflection coating with a thickness of 75nm and a refractive index of 2.0;

[0032] (2) Backside polishing: Put the silicon wafers processed in step (1) into the silicon wafer basket, put them into the polishing solution in the chemical polishing tank for chemical polishing for 5 minutes, the chemical polishing temperat...

Embodiment 2

[0038] (1) Front-end process: Firstly, monocrystalline silicon wafers are placed in a NaOH solution with a mass concentration of 1.2% at 80°C for 15 minutes to form a pyramidal textured structure on the front and back sides, which are then cleaned with pure water and dried; Phosphorus is diffused on the front side of the chip to form an emitter (prior art), and the diffusion resistance is 70R 方 ; With a concentration of 7% HF solution, the phosphosilicate glass on the surface of the silicon wafer is cleaned and dried; then a layer of nitride is deposited on the front of the silicon wafer by PECVD (enhanced plasma vapor deposition method, prior art) Silicon anti-reflection coating with a thickness of 75nm and a refractive index of 2.0;

[0039] (2) Backside polishing: Put the silicon wafers processed in step (1) into the silicon wafer basket, put them into the polishing solution in the chemical polishing tank for chemical polishing for 5 minutes, the chemical polishing temperat...

Embodiment 3

[0051] The difference between this embodiment and Example 1 lies in the formula of the etching slurry: the content of each component in the etching slurry is: concentrated phosphoric acid 15%, terpineol 8%, ethyl cellulose 12%, graphite powder 35% %, polyethylene glycol 30%. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com