Support of light emitting diode and preparation method

A technology for light-emitting diodes and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of poor thermal conductivity, too many molds, and high costs, so as to reduce production costs, simplify manufacturing processes, and improve The effect of suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

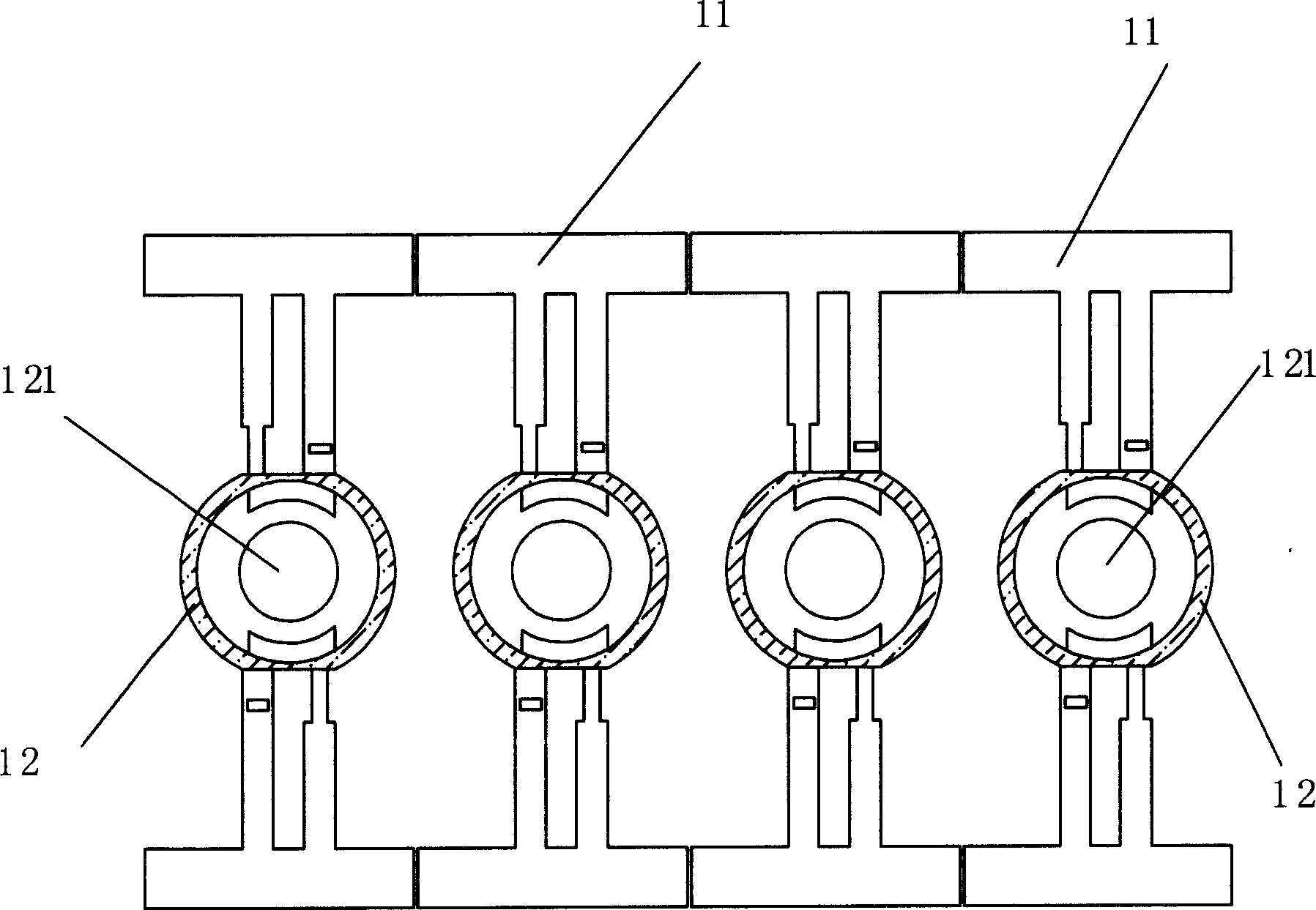

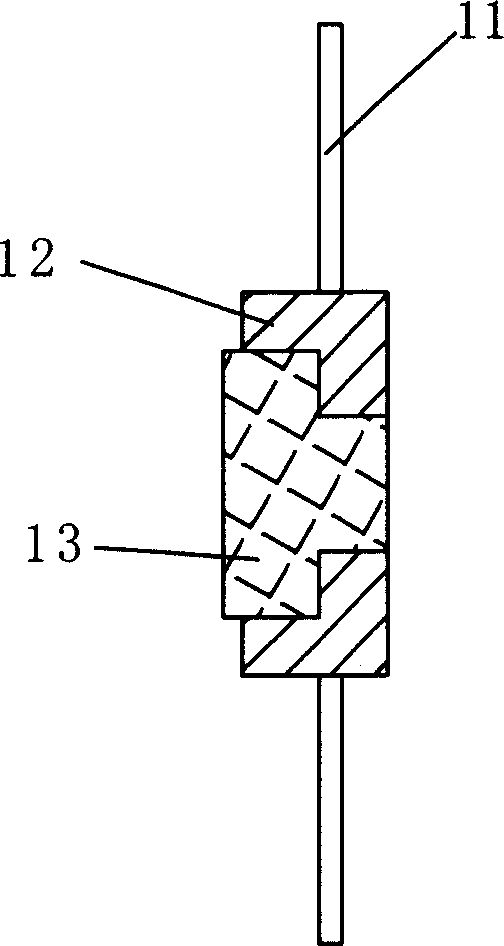

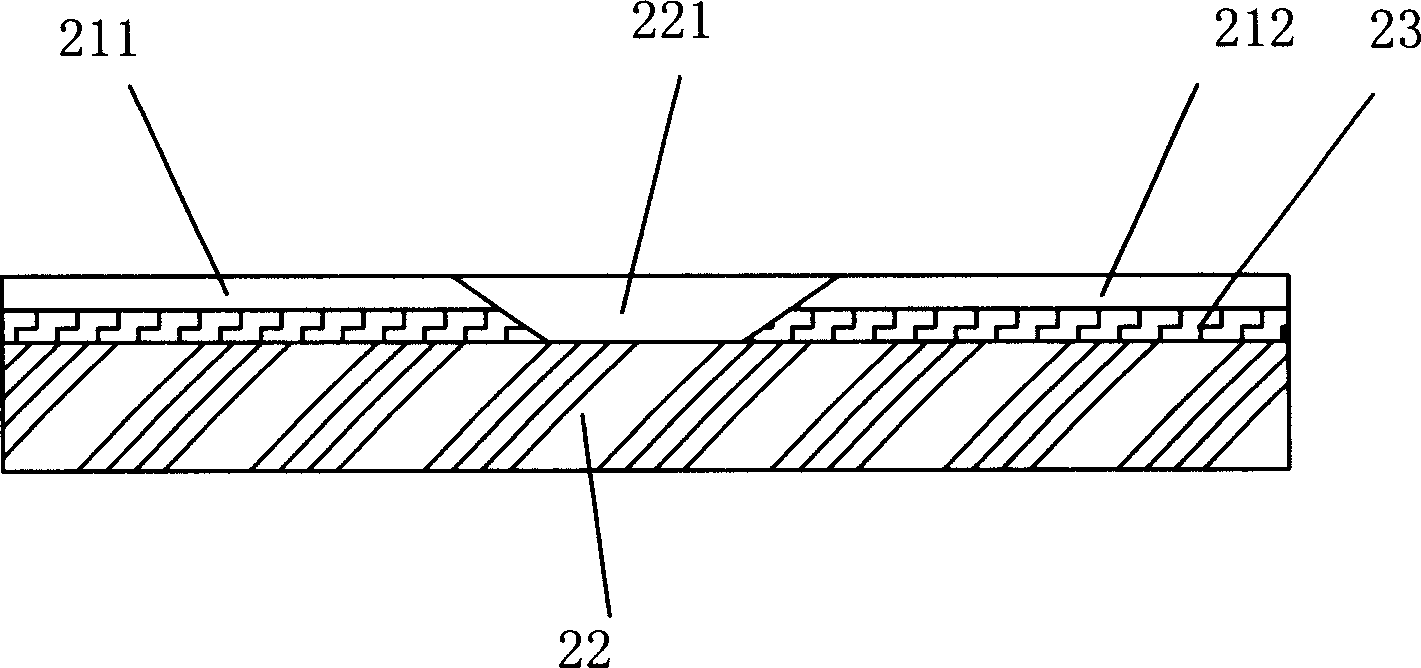

[0027] see Figure 7 to Figure 10 , the manufacturing method of a kind of light-emitting diode support of the present invention comprises following process: 1) make the circuit board 4 with electrode by the organic resin-based metal-clad plate through printed circuit board process; 2) make through-hole 43 on the circuit board 4 ; 3) Fix the copper piece 6 in the said through hole 43 . After the support is formed, the chip can be fixed on the copper piece. In step 1), the electrodes 5 are made by the printed circuit board process on the surfaces of both ends of the circuit board. In this embodiment, the electrodes are formed by etching on the circuit board through the existing printed circuit board process; Electrodes 5 are formed on the top surface 411, the bottom surface 413 of the end portion and the side surface 412 connecting the top and bottom surfaces.

[0028] see Figure 7 to Figure 9 , during mass production, several light-emitting diode brackets can be made on a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com