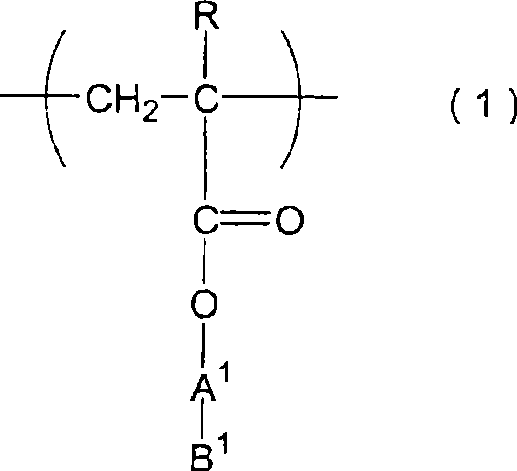

Liquid crystal orientation agent, liquid crystal orientation film and liquid crystal display element

A technology of liquid crystal aligning agent and repeating unit, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problem of insufficient improvement of afterimage performance, and achieve the effects of excellent afterimage resistance and coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

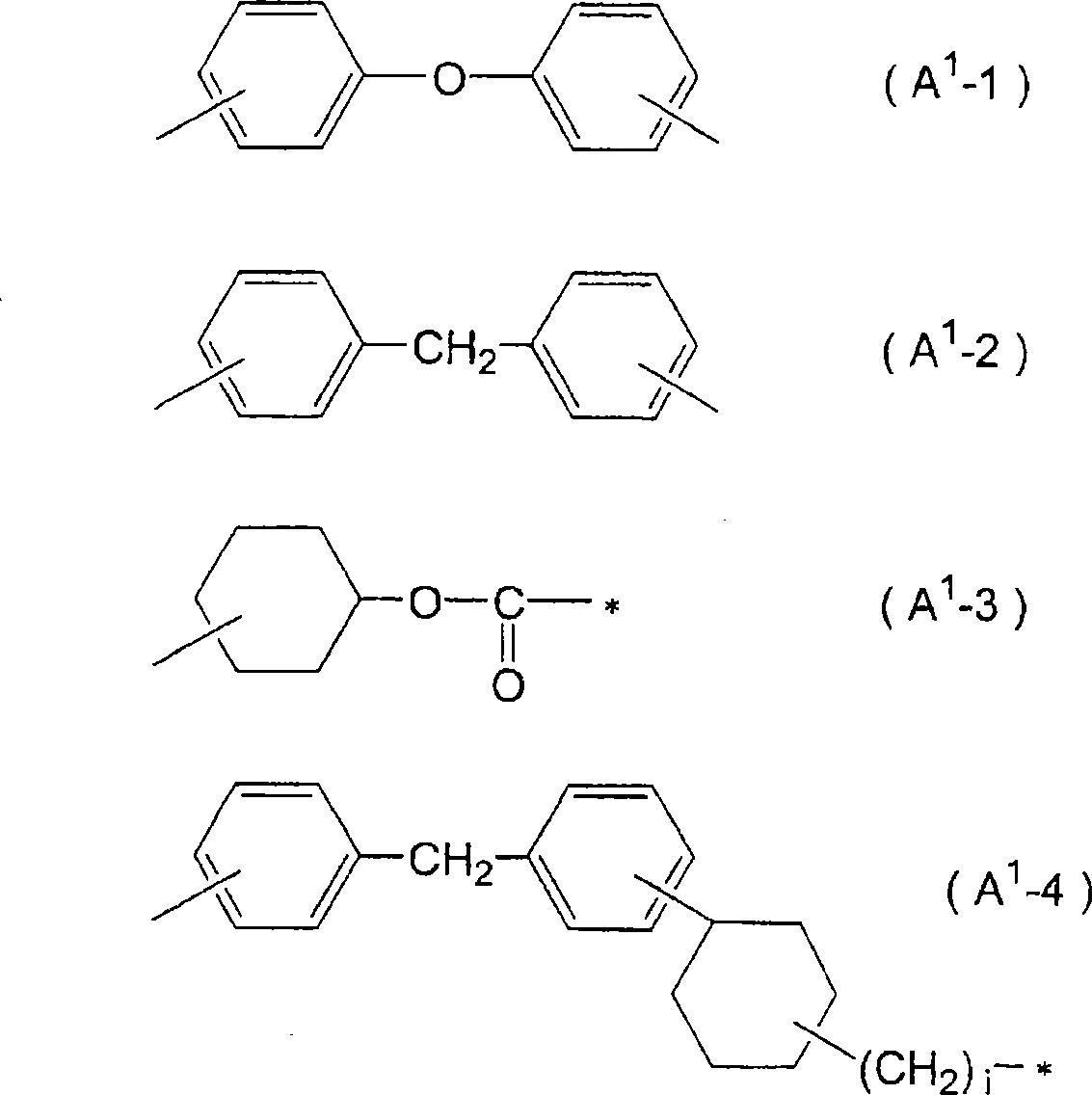

Method used

Image

Examples

Synthetic example 1

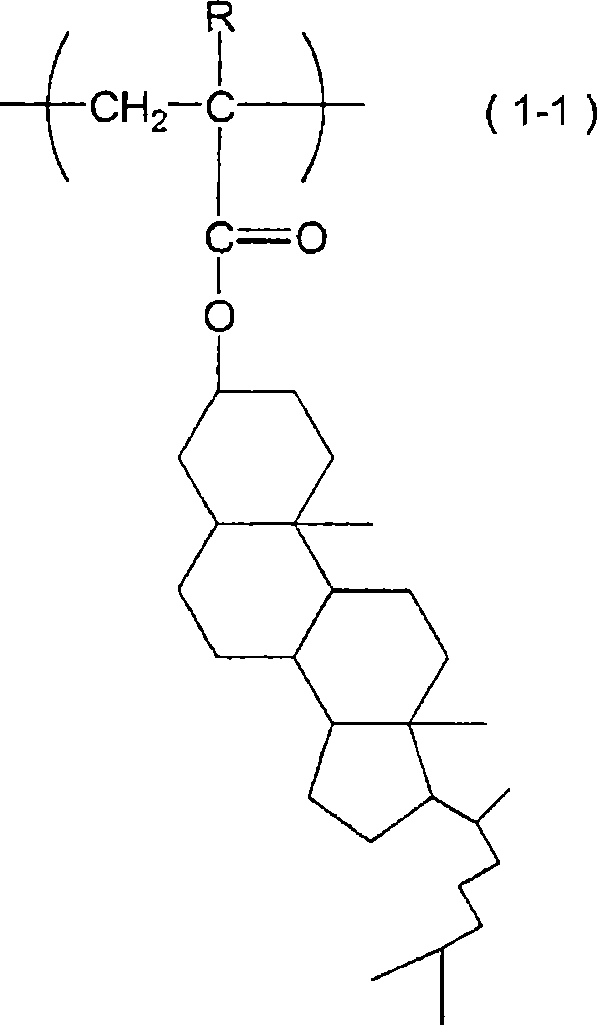

[0225] Synthesis Example 1 (Synthesis of Compound (1'))

[0226] Cholesteryl methacrylate is synthesized according to the following reaction scheme 1.

[0227]

[0228] Reaction scheme 1

[0229] Dissolve 80g of β-cholesterol in 800ml of dehydrated tetrahydrofuran (THF), add 27g of triethylamine, slowly add 36g of methacryloyl chloride dropwise, and stir at room temperature for 3 hours to react. After completion of the reaction, triethylamine hydrochloride was removed by filtration, THF was distilled off under reduced pressure, and 400 ml of chloroform was added. This solution was washed with water, and the organic layer was dried over magnesium sulfate, and then chloroform was distilled off under reduced pressure. Then, recrystallization was performed with ethanol to obtain 54 g of cholestanyl methacrylate as a white solid (yield: 57%).

[0230] In addition, in this Synthesis Example 1, the above operation was repeated according to the above synthesis route as needed, s...

Synthetic example 2

[0231] Synthesis Example 2 (Synthesis (1) of Polymer (1))

[0232] In a four-necked flask equipped with a stirring rod, a three-way valve and a thermometer, 15 g (0.033 moles) of cholestanyl methacrylate prepared in the above-mentioned Synthesis Example 1, glycidyl methacrylate 13g (0.090 mole) of ester, 7.2g (0.084 mole) of methacrylic acid, 7.2g (0.069 mole) of styrene and 7.2g (0.044 mole) of N-cyclohexylmaleimide, then add diethylene glycol as solvent 53 g of ethyl methyl ether, 2.2 g of 2,2'-azobis(2,4-dimethylvaleronitrile) as a polymerization initiator, and 0.96 g of α-methylstyrene dimer as a molecular weight modifier . This was bubbled with a nitrogen stream for about 10 minutes to ventilate the system with nitrogen, and then reacted at 70° C. for 5 hours under a nitrogen atmosphere to obtain a solution containing 48% by weight of the polymer (1-1). The molecular weight of the polymer (1-1) was measured by GPC, Mw=96000, Mw / Mn=7.9, and no peak due to residual monome...

Synthetic example 3

[0233] Synthesis Example 3 (Synthesis (2) of Polymer (1))

[0234] In the above Synthesis Example 2, except that 7.2 g (0.042 moles) of N-phenylmaleimide was used instead of N-cyclohexylmaleimide, the same procedure was carried out as in Synthesis Example 2 to obtain a polymer compound containing 48% by weight. solution of compound (1-2). The molecular weight of the polymer (1-2) was measured by GPC, Mw=108000, Mw / Mn=6.5, and no peak due to residual monomer was identified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com