Wire control braking system and braking method thereof

A technology of brake-by-wire and control system, which is applied in the direction of brake transmission, brake, transportation and packaging, etc., to achieve the effect of simple and easy implementation, overcoming the problem of inability to adjust the gap, and overcoming the self-adaptive adjustment of the pressing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

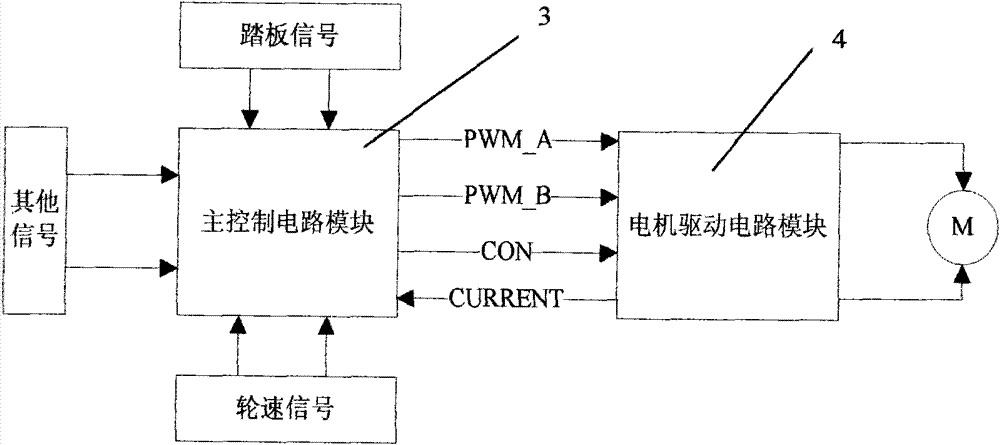

[0021] Such as figure 1 As shown, in the brake-by-wire system, the main control circuit module 3 controls the motor speed, steering and output torque through the PWM_A and PWM_B duty ratio signals, and controls whether the PWM_A and PWM_B output duty ratio signals by enabling the control port CON , use the feedback current CURRENT to judge the motor stall and load conditions. For example, when the feedback current CURRENT is detected to reflect that the friction plate is separated from the brake disc, then control the CON signal to determine whether PWM_A and PWM_B output duty ratio signals.

[0022] In order to realize brake safety control of ABS, ASR, EPS, etc. of brake-by-wire, real-time and accurate provision of ideal brake pressing force is the key to realize the above-mentioned control system. Since the set PWM duty ratio corresponds to the maximum stalling torque that the motor can provide, the larger the PWM duty ratio is set, the greater the stalling torque will be. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com