Hydrojet Magnetic Resin Adsorption Reactor

A magnetic resin and hydraulic jet technology, which is applied in chemical instruments and methods, ion exchange water/sewage treatment, ion exchange, etc., can solve the problem of affecting the normal performance of the adsorption performance of solid magnetic resin particles, the inability to achieve continuous operation, and the separation of resin solutions Difficulties and other problems, to achieve the effects of small footprint, fast adsorption reaction speed, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

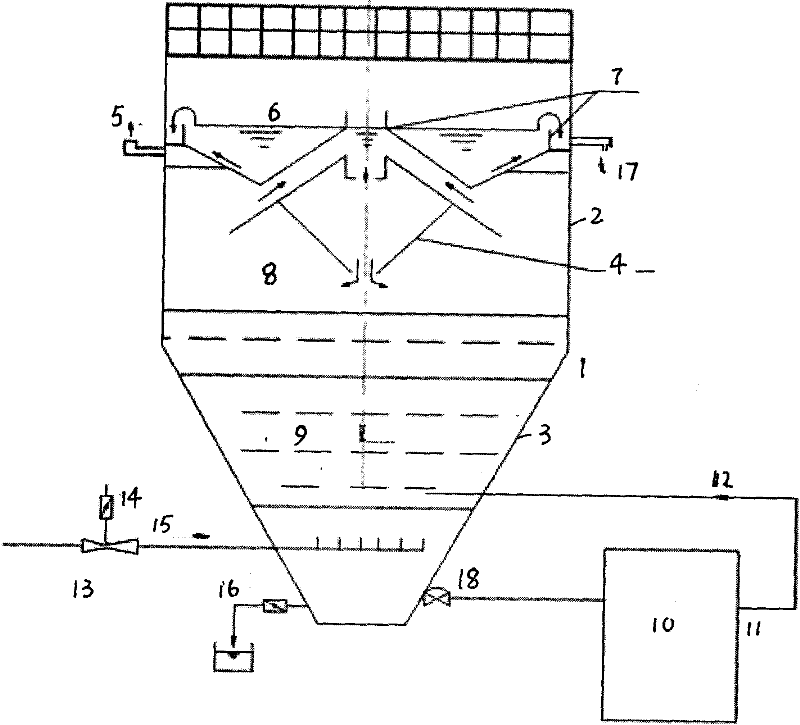

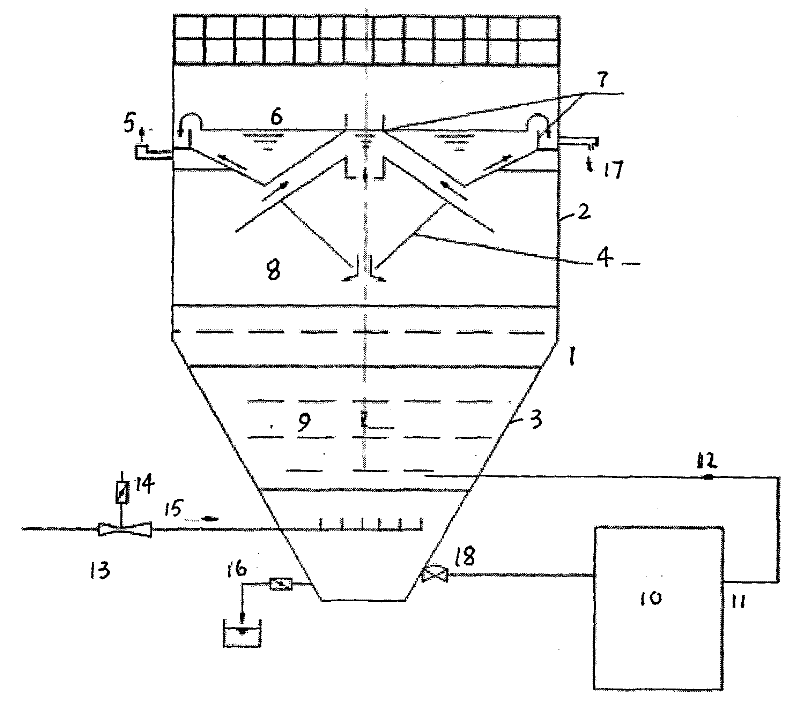

[0020] The interior of the cylinder reactor is filled with 5-20% by volume of magnetic particle resin to form a resin layer, and the diameter of the solid spherical particle magnetic resin is between 60-150 μm. The incoming water enters the interior of the reactor through the hydraulic jet and flows upward through the resin layer to contact. The air bubbles brought by the jet fully contact the sewage and resin, which promotes the full contact between the adsorption groups on the resin surface and the pollutants in the water, and at the same time avoids the magnetic resin. Static attraction adhesion;

[0021] The reactor is a steel structure, the ascending velocity is controlled at 9-15m / h, and the hydraulic retention time is 1-6h, all of which can achieve the purpose of the present invention. The hydraulic jet is composed of three parts: nozzle, suction chamber and diffuser. Using the principle of jet negative pressure, the strong water flow and air are mixed and sprayed to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com