Calcium sulfite particles and preparation method

A calcium sulfite and manufacturing method technology, applied in the direction of calcium/strontium/barium sulfite, etc., can solve the problems of low packing density, low efficiency of immediate chlorine removal, low content of calcium sulfite, etc., and achieve uniform forming and improved The effect of dechlorination effect

Inactive Publication Date: 2010-05-26

上海亚弘过滤器材股份有限公司

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The object of the present invention is to provide a kind of calcium sulfite granule, described this calcium sulfite granule will solve the low content of calcium sulfite in the prior art, low packing density per unit volume, low instant dechlorination efficiency, unit gram The technical problem of low chlorine removal capacity of heavy or unit volume calcium sulfite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0062] materials

[0063] The above formula consumptions are all percentages by weight.

Embodiment 2

[0065] materials

[0066] The above formula consumptions are all percentages by weight.

Embodiment 3

[0068] materials

[0069] materials

[0070] The above formula consumptions are all percentages by weight.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Login to View More

Abstract

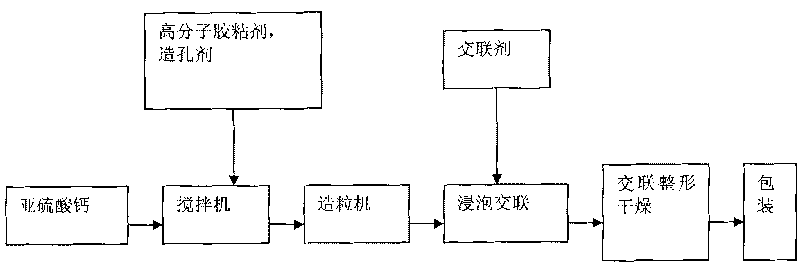

The invention provides calcium sulfite particles. The calcium sulfite particles are in a cylindrical structure, the surfaces of the calcium sulfite particles are provided with pores, and the content of the component of calcium sulfite is more than 90%. The invention also provides a method for preparing the calcium sulfite particles, which comprises the following steps: weighing each substance; preparing a water solution; mixing and stirring evenly; granulating; crosslinking; pre-crosslinking, baking and shaping; and finally, drying and packaging. The invention overcomes the limitation of the prior art and also solves the problem of granulation of the calcium sulfite well. Short cylindrical calcium sulfite the surface of which is in a micropore structure is prepared. Because a plurality of micropores are distributed at the surfaces of the particles, the special structure enables water molecules to fully contact with the calcium sulfite directly and enhances the dechlorination effect greatly.

Description

Technical field: [0001] The invention relates to the field of chemical industry, in particular to a calcium sulfite, in particular to a calcium sulfite particle and a production method. Background technique: [0002] Calcium sulfite is a white crystalline powder with a density of 1.595. It loses crystal water at 100°C and decomposes at 650°C. It is slightly soluble in water. It is slowly oxidized to calcium sulfate in the air and decomposed in acid to produce sulfur dioxide. Calcium sulfite is produced by passing sulfur dioxide into milk of lime or lime water or by reacting sodium sulfite with calcium sulfate. [0003] Calcium sulfite can remove residual chlorine in water, including compound residual chlorine NH 2 CL, NHCL 2 and NCL 3 and free residual chlorine CLO-, HOCL, CL 2 etc. Compared with traditional activated carbon, the dechlorination effect is more efficient, safe, high temperature resistant, and does not breed bacteria. It is widely used in various water rem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01F11/48

Inventor 刘武义王钦华

Owner 上海亚弘过滤器材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com