Channel seepage-guiding and non-return system

A channel and anti-return technology, applied in irrigation pipelines, applications, buildings, etc., can solve the problems of deformation of concrete channels, affecting the service life of concrete anti-seepage channels, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

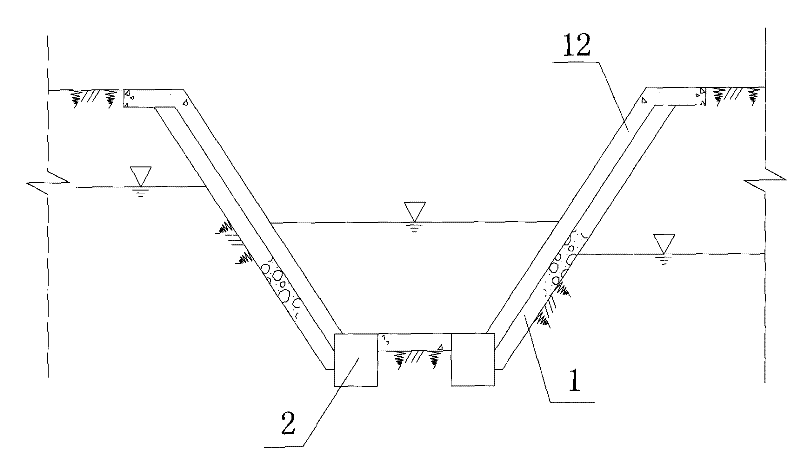

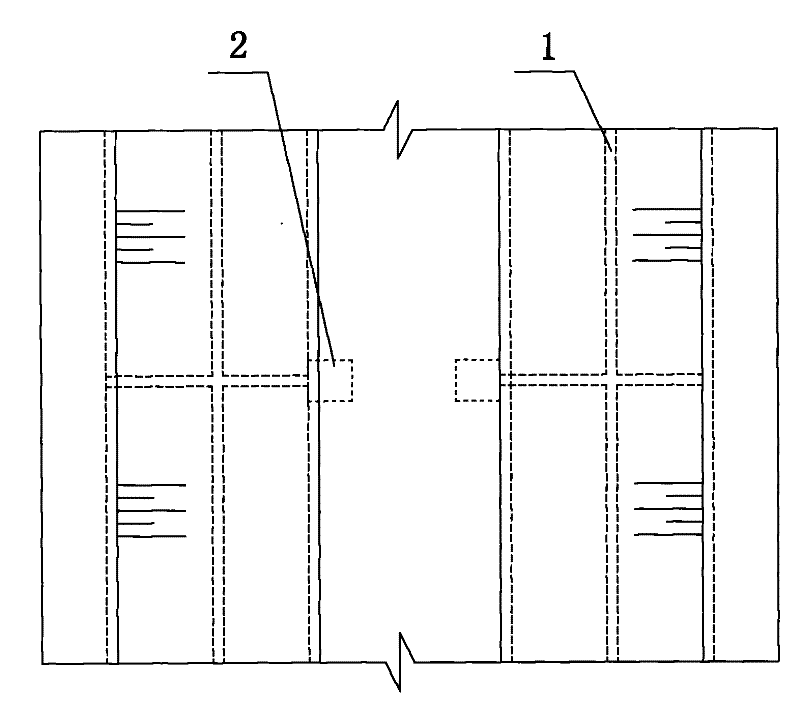

[0023] like Figure 1~5 As shown, a channel seepage anti-reverse system, including vertical and horizontal grid drainage body 1 and seepage anti-reverse device 2;

[0024] The vertical and horizontal grid drainage body 1 is arranged under the concrete anti-seepage panel 12 of channel slope protection; the grid of the vertical and horizontal grid drainage body 1 is filled with sand and gravel filter material; the vertical and horizontal grid drainage body 1 The lower end is connected with the seepage arrester 2;

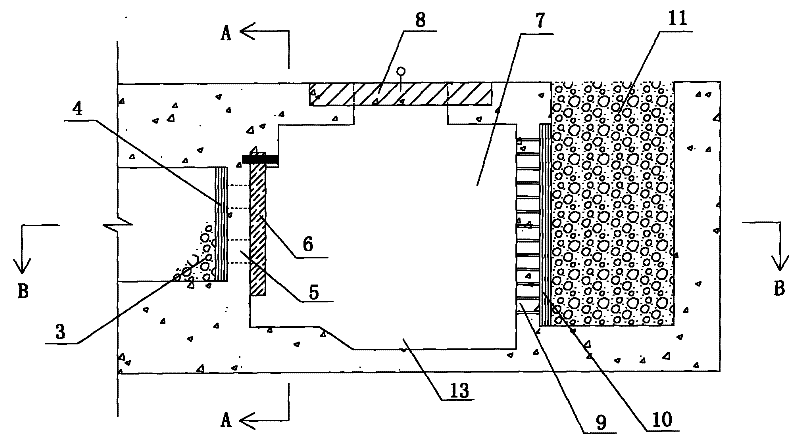

[0025] The seepage arrester 2 is arranged in the groove of the bottom plate of the channel, and has a concrete shell; the top of the seepage arrester 2 is flush with the bottom of the channel; the internal structure of the seepage arrester 2 is horizontally as follows: The first filter layer 3, the first geotextile layer 4, the first porous concrete interlayer 5, the steel wire mesh flexible plastic sheet 6, the water collection chamber 7, the second porous concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com