Double-shaft groove forming machine

A trough forming machine and power shaft technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of complex structure, expensive equipment, shallow groove forming depth, etc., and achieve the effect of ensuring continuity and verticality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

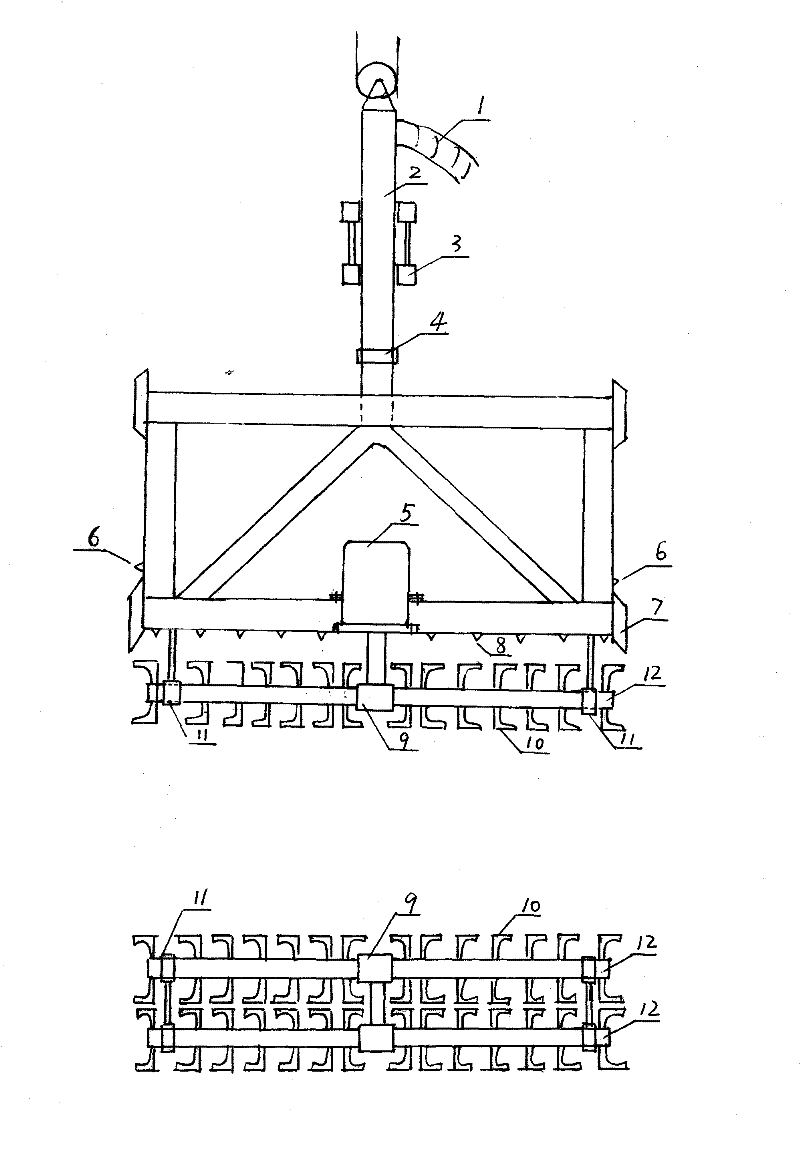

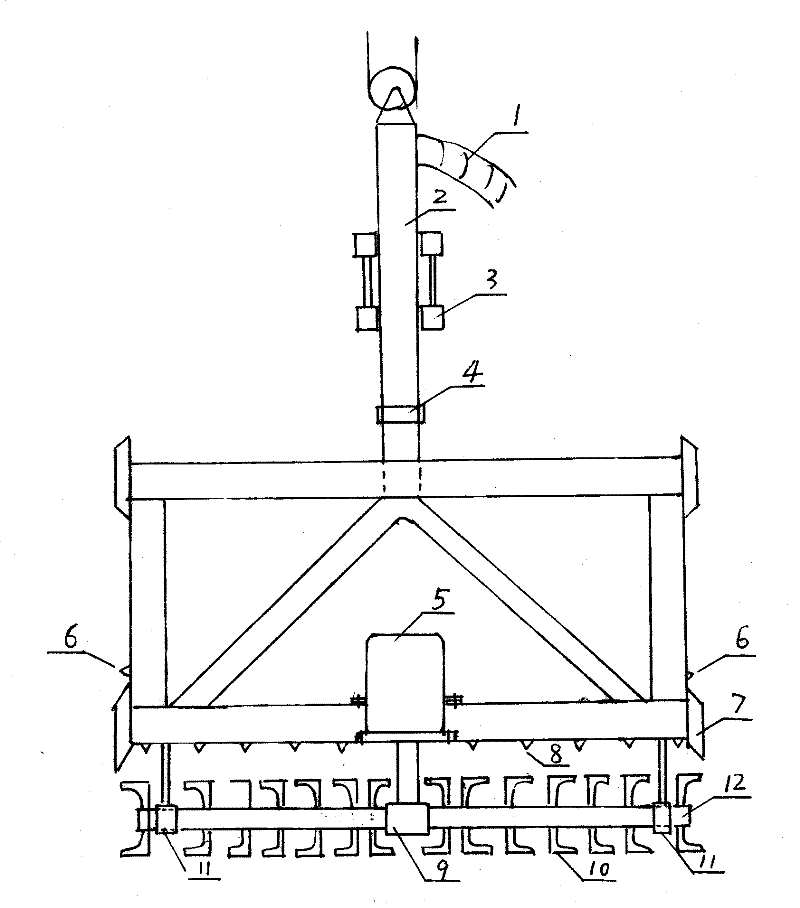

[0015] The accompanying drawing shows a specific embodiment of the present invention, which includes a slurry supply system, a guide system and an excavation system.

[0016] 1. Pulp supply system:

[0017] The slurry supply system is composed of a slurry supply hose 1, a slurry supply pipe 2, a water spray nozzle 8, a side nozzle 6, a high pressure slurry pump and other pipelines.

[0018] The slurry supplied by the high-pressure mud pump is sprayed from the water spray nozzle. The slurry sprayed from the water spray nozzle and the rotating scimitar cut the formation to make slurry. The slurry containing mud sand overflows from the tank and naturally flows back to the sedimentation tank, where it settles. After that, the slurry returns to the storage tank, and then the high-pressure mud pump in the storage tank supplies slurry to the tank, and so on.

[0019] The function of the side spray nozzle is to flush the mud partitions on both sides of the double-numbered trough section, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com