Electroconductibility single-hole diluting method for detecting seepage speed

A technology of seepage velocity and conductivity, which is applied in fluid velocity measurement, velocity/acceleration/shock measurement, measuring devices, etc., and can solve problems such as prone to radioactive accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

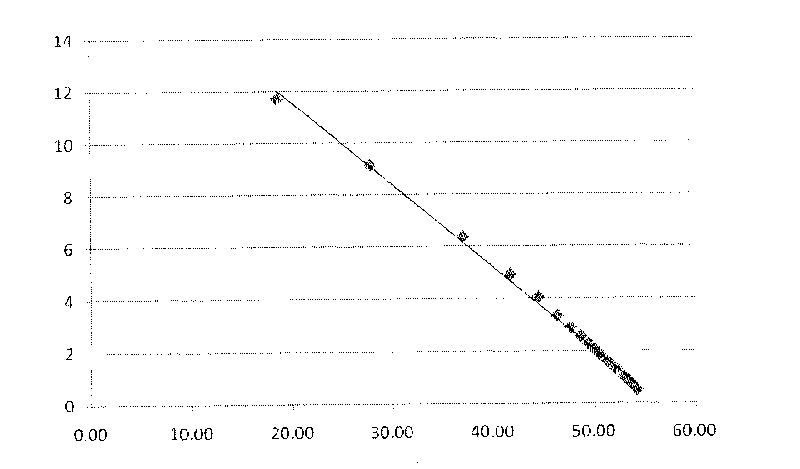

[0062] The conductivity single-hole dilution method for measuring seepage velocity includes: selecting the position of the measuring hole and drilling the hole, selecting the tracer according to the different conductivity of the water body of the drilling hole on the spot, and measuring the relationship between the conductivity and the concentration of the tracer solution in the laboratory. The tracer solution is put into the hole, the conductivity of the water body in the hole is measured, and the seepage flow rate is calculated by using the change rate of the measured conductivity.

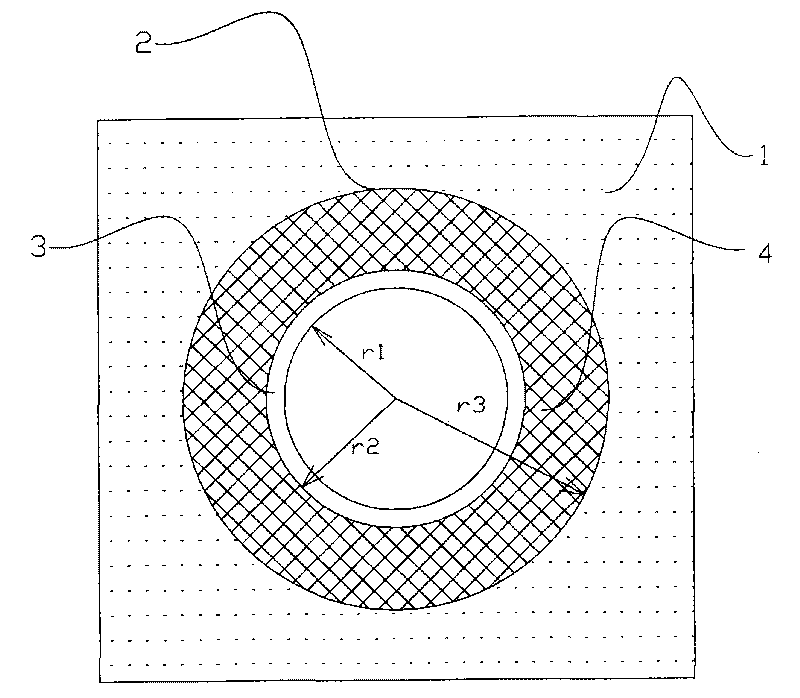

[0063] Select the geologically stable area to be measured, and drill holes at the position of no broken zone. The hole depth is below the estimated aquifer 1. The measuring hole 2 has a built-in filter tube 3; the filter tube 3 is equipped with a gravel layer 4, see figure 1 ;

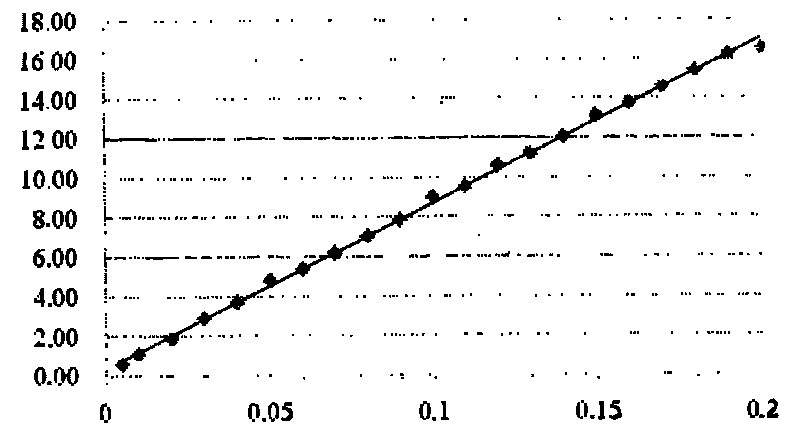

[0064] The tracer was selected according to the different conductivity of the drilling water body on site, and the mea...

Embodiment 2

[0077] The conductivity single-hole dilution method for measuring seepage velocity includes: selecting the position of the measuring hole and drilling the hole, selecting the tracer according to the different conductivity of the water body of the drilling hole on the spot, and measuring the relationship between the conductivity and the concentration of the tracer solution in the laboratory. The tracer solution is put into the hole, the conductivity of the water body in the hole is measured, and the seepage flow rate is calculated by using the change rate of the measured conductivity.

[0078] In the area to be measured, select geologically stable, no broken zone to drill holes, the hole depth is below the estimated aquifer 1, and the measuring hole 2 has a built-in filter tube 3; the filter tube 3 has no gravel layer outside;

[0079] The tracer was selected according to the different conductivity of the drilling water body on site, and the measured conductivity of the drilling...

Embodiment 3

[0089] The conductivity single-hole dilution method for measuring seepage velocity includes: selecting the position of the measuring hole and drilling the hole, selecting the tracer according to the different conductivity of the water body of the drilling hole on the spot, and measuring the relationship between the conductivity and the concentration of the tracer solution in the laboratory. The tracer solution is put into the hole, the conductivity of the water body in the hole is measured, and the seepage flow rate is calculated by using the change rate of the measured conductivity.

[0090] In the area to be measured, select geologically stable, no broken zone to drill holes, the hole depth is below the estimated aquifer 1, and the measuring hole 2 has a built-in filter tube 3; the filter tube 3 has no gravel layer outside;

[0091] The tracer was selected according to the different conductivity of the drilling water body on site, and the measured conductivity of the drilling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com