Electrical operating mechanism for switchgear

A technology of using electric operation and switching equipment, applied in the field of electric operation mechanism, can solve the problems such as the inability to meet the requirements of use, and achieve the effects of excellent transmission characteristics, small size and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

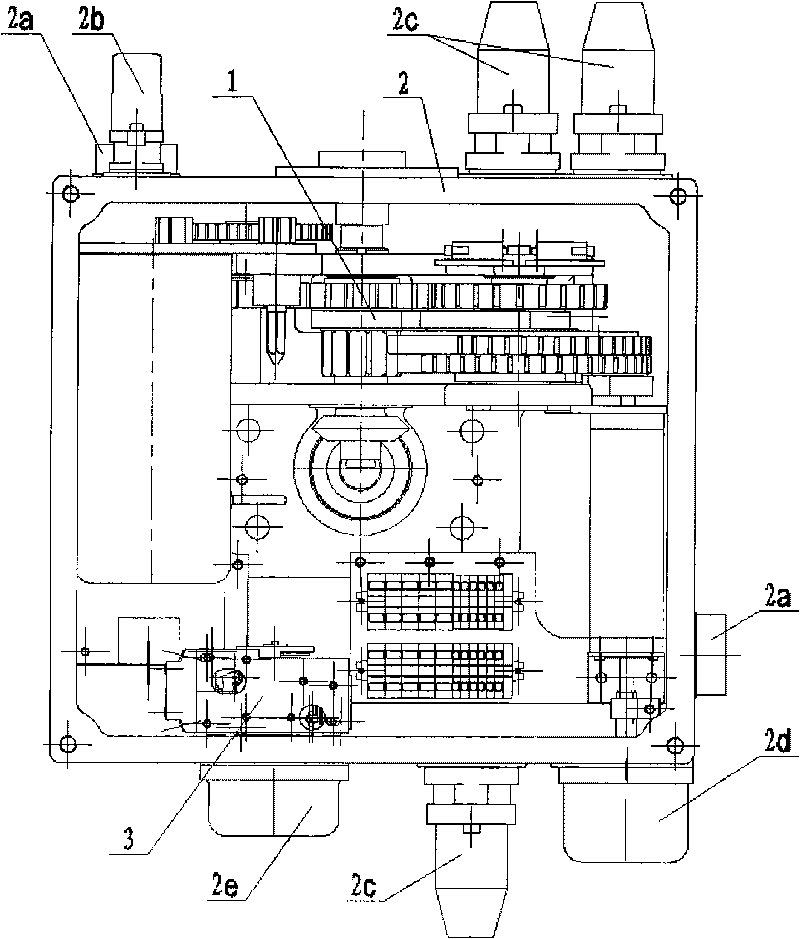

[0031] like figure 1As shown, the present invention is mainly made up of core 1, mechanism box 2 and manual operation interlocking device 3. The core 1 and manual operation interlocking device 3 are fixed in the mechanism box 2, and the mechanism box 2 is provided with a box Ventilation window 2a for internal and external ventilation, connectors 2b and 2c for leading and introducing electrical connection wires of the mechanism, opening and closing position indicator 2d, protective cover 2e for manual operation interlocking device.

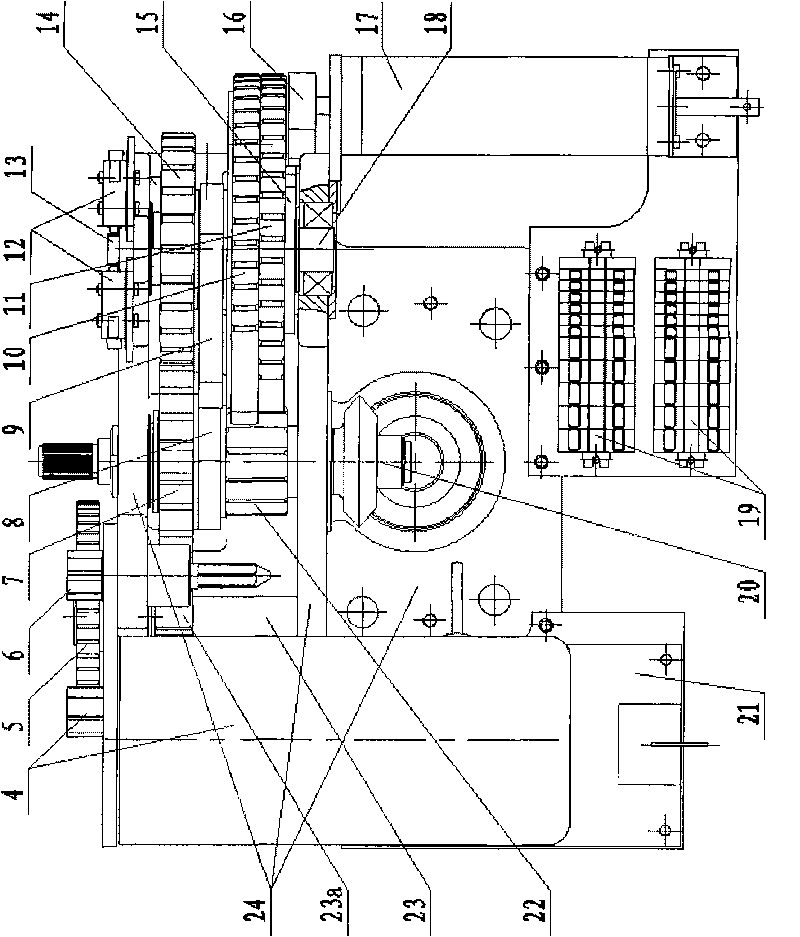

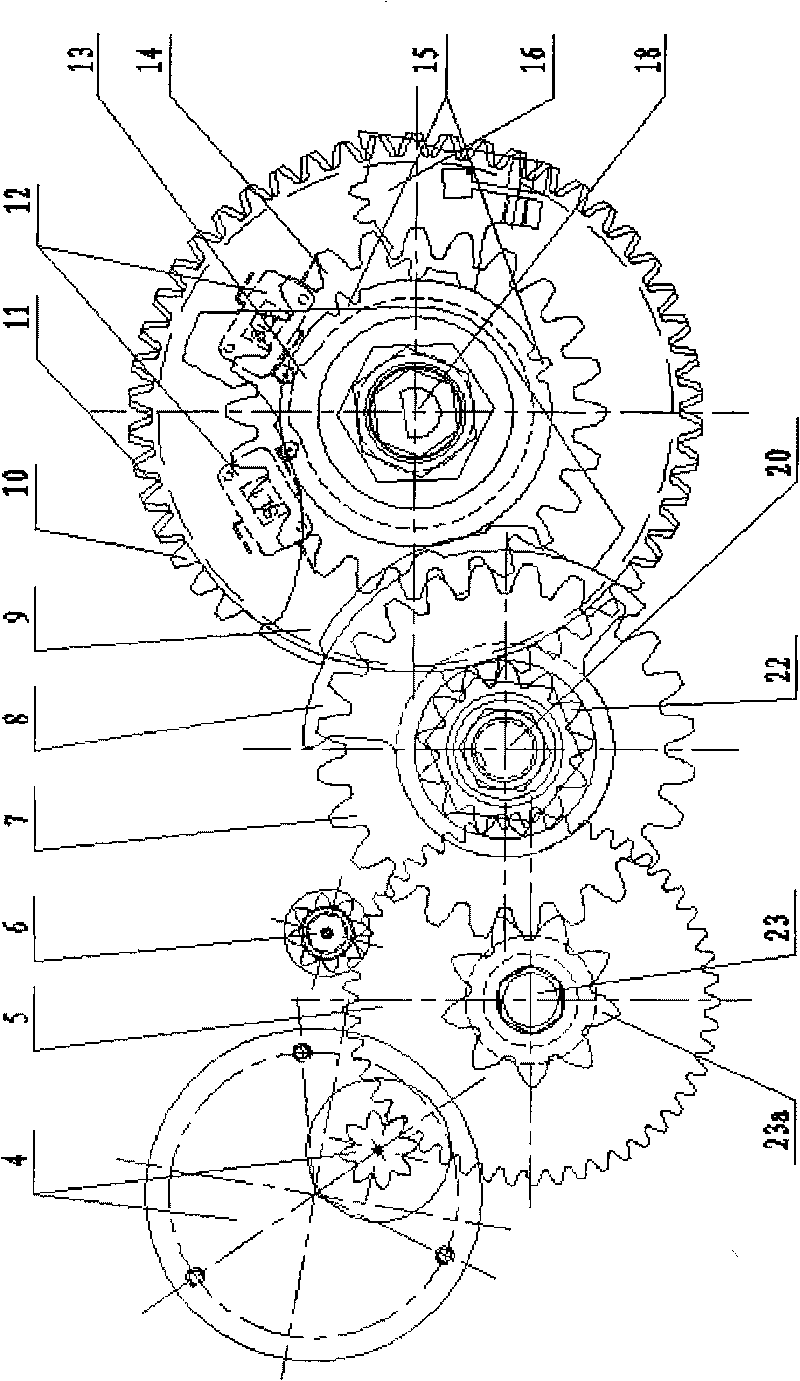

[0032] In this embodiment, the steering of the output shaft of the mechanism is counterclockwise for opening and clockwise for closing. like Figure 4 shown.

[0033] like figure 2 , image 3 As shown, the mechanism core part includes a cast aluminum mechanism bracket 24 on which a main shaft 18 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com